Decelerating wear-resisting device and boiler furnace equipped therewith

A boiler furnace and anti-wear technology, which is applied in the direction of burning fuel in a molten state, lighting and heating equipment, fluidized bed combustion equipment, etc., can solve the problems of wearing of the heating surface and incompatibility of the anti-wear device, so as to increase the strength and avoid Large-scale modification, eliminating the effect of airflow lateral turbulence wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0041] One aspect of the present invention provides a deceleration and anti-wear device, which can be used to protect the heating surface in a circulating fluidized bed boiler.

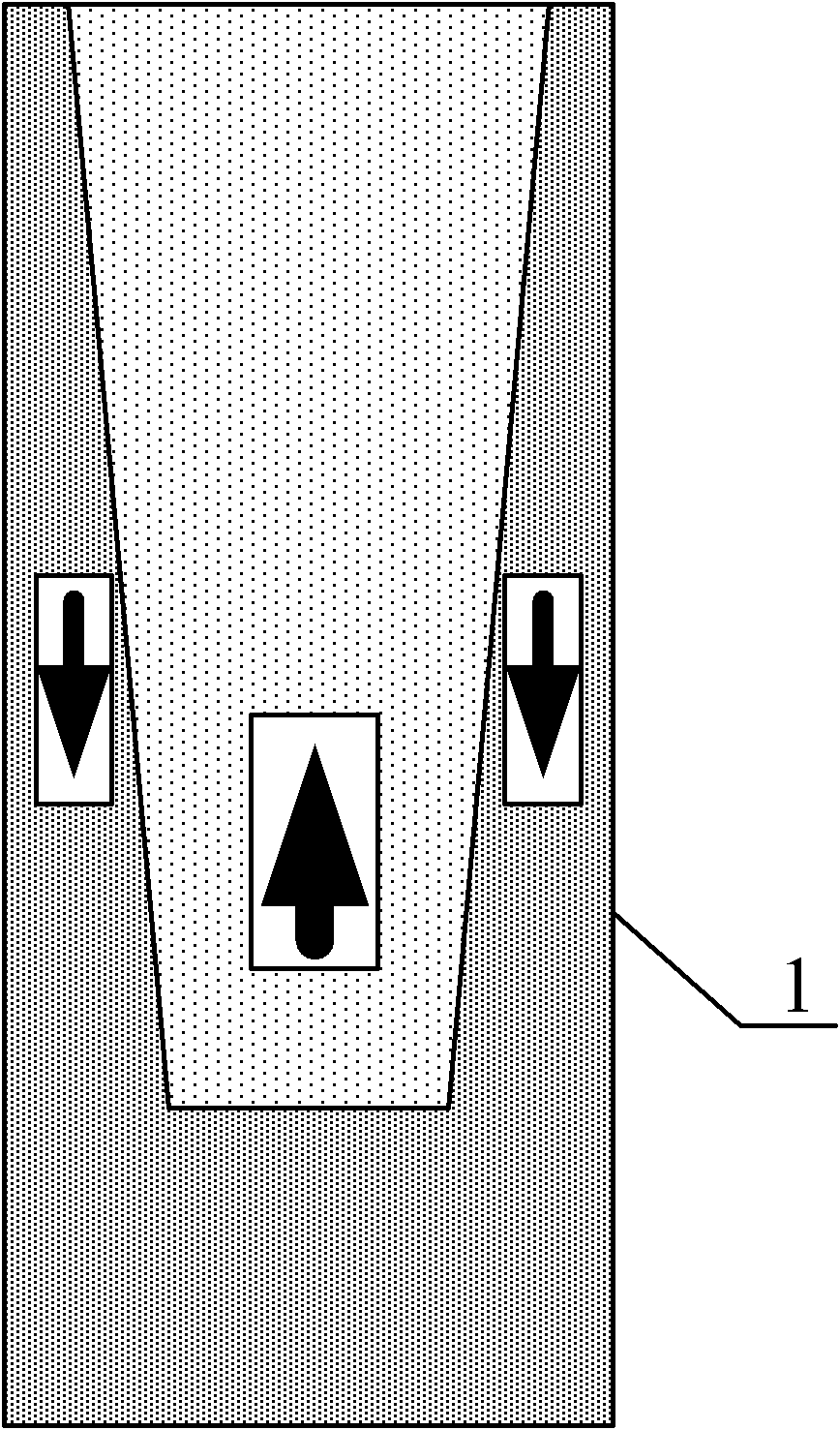

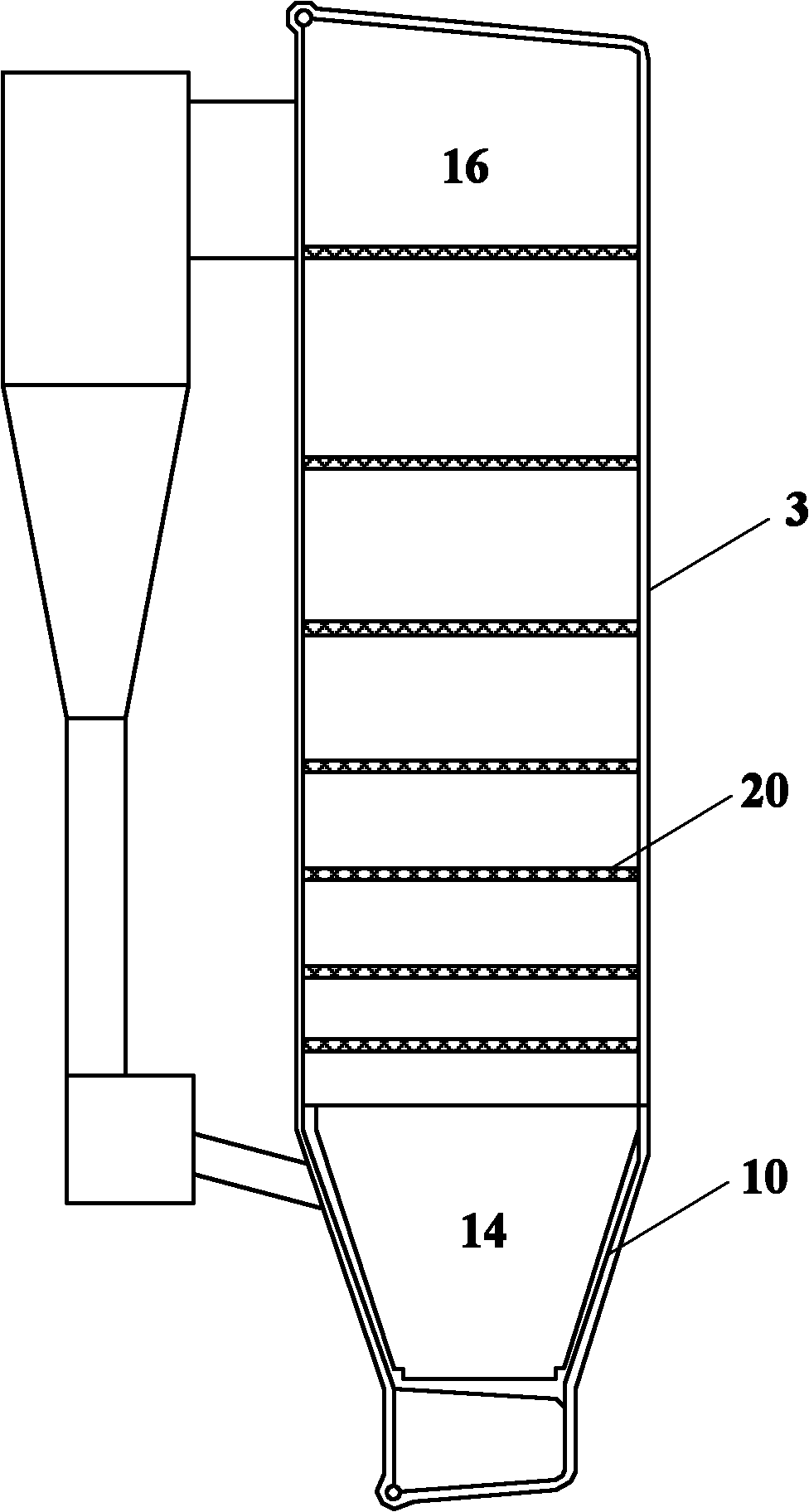

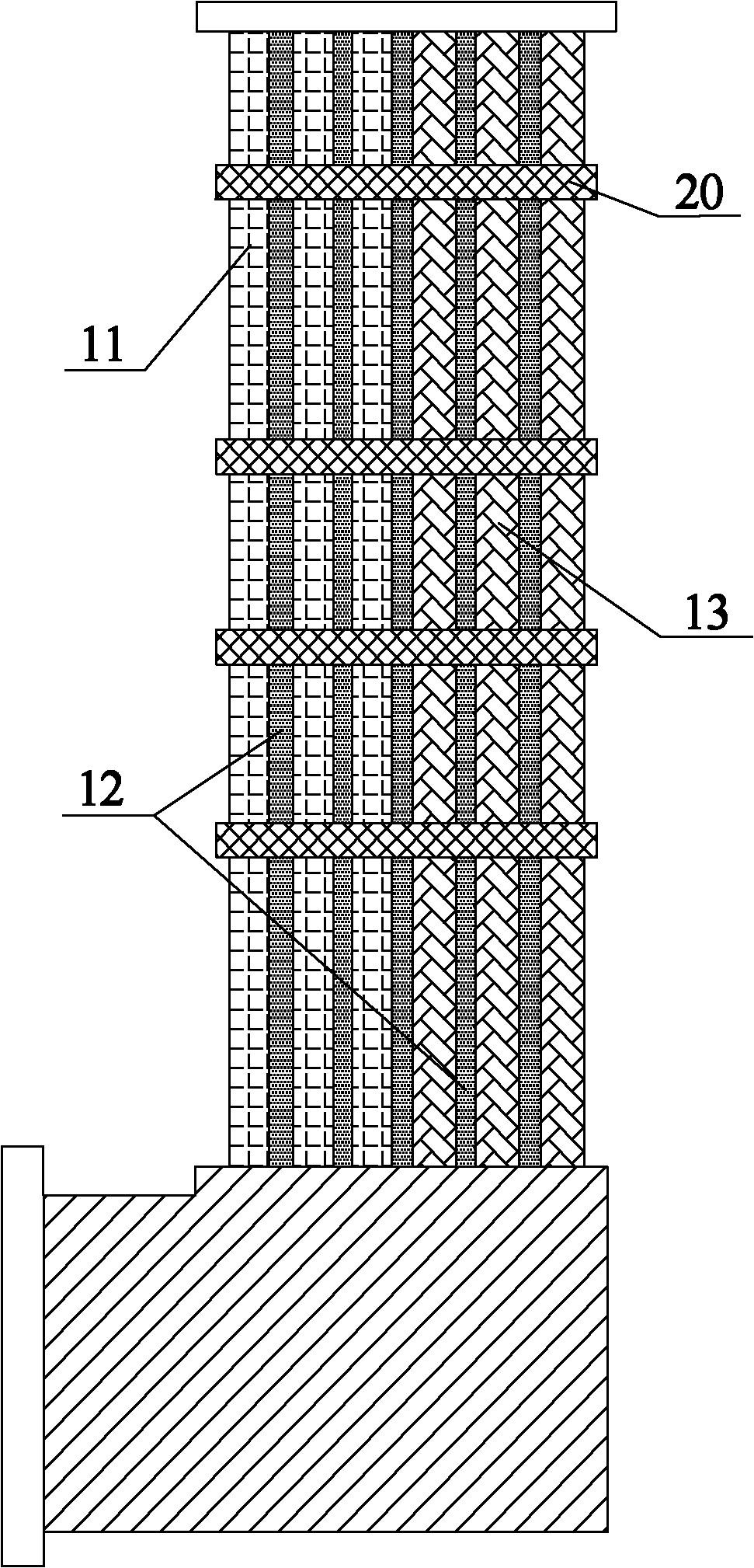

[0042] Such as figure 2 , image 3 and Figure 4 As shown, the deceleration and anti-wear device includes deceleration and anti-wear shrouds 20 , and the deceleration and anti-wear shrouds 20 are arranged on the heating surface at a certain interval along the height direction of the furnace 10 of the circulating fluidized bed boiler. The wear-reducing shroud 20 includes a shroud main body 21, pins 25, and a tortoise shell net 23, wherein the pins 25 are welded to the water wall cooling pipe 11 forming the water wall, the screen heating surface cooling pipe 13 forming the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com