Focal plane detection device for projection lithography

A detection device and projection light technology, which are used in photoplate-making process exposure devices, microlithography exposure equipment, optics, etc., can solve the problems of high imaging quality requirements of CCD lenses and limited measurement range, and achieve high-precision focal plane measurement. , The effect of improving the focus detection measurement range and reducing the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

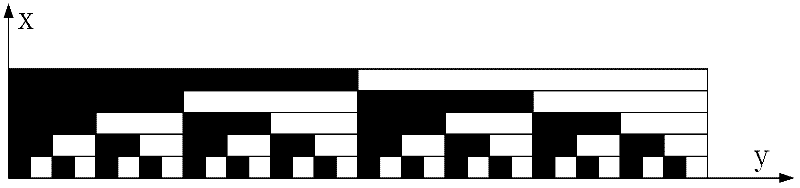

[0019] The invention uses a binary coded grating instead of a traditional slit to realize large-scale and high-precision focal plane detection.

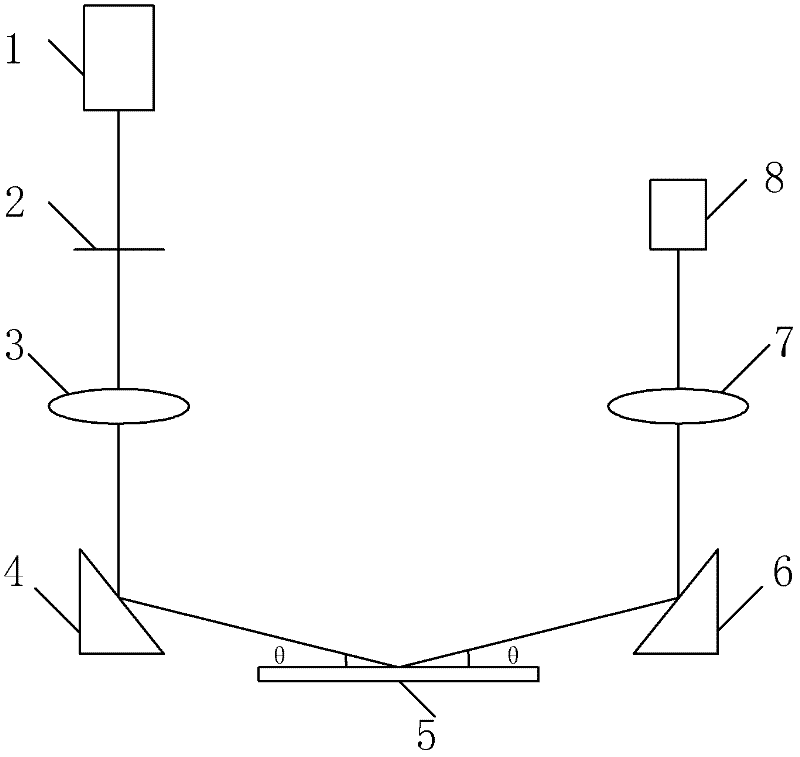

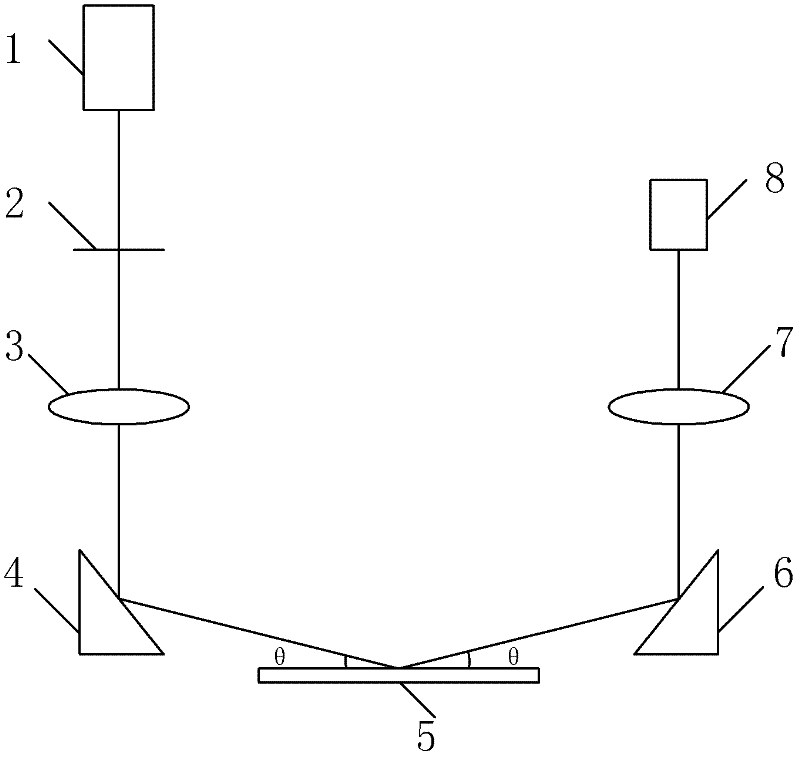

[0020] The present invention is composed of an illumination source 1, an absolute coding grating 2, a projection imaging system 3, a first reflector 4, a surface to be measured 5, a second reflector 6, a focus detection mark amplification system 7 and a detection device 8. The light emitted by the illumination source 1 is irradiated on the absolute coded grating 2, and the light modulated by the absolute coded grating 2 passes through the projection imaging system 3 and is projected and imaged by the mirror 4 onto the surface to be measured 5, and after being reflected by the surface to be measured 5 , enters the focusing mark magnification system 7 through the mirror 6 and is received by the detection device 8 . The detector 8 is used to receive the absolute coded grating image whose position changes with the height of the surface t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com