Real-time detection method for defect points of cloth

A real-time detection and cloth technology, applied in the field of textile production, can solve the problems of high missed detection rate, slow detection speed, low detection accuracy, etc., achieve high accuracy, fast detection speed, and reduce the amount of computation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

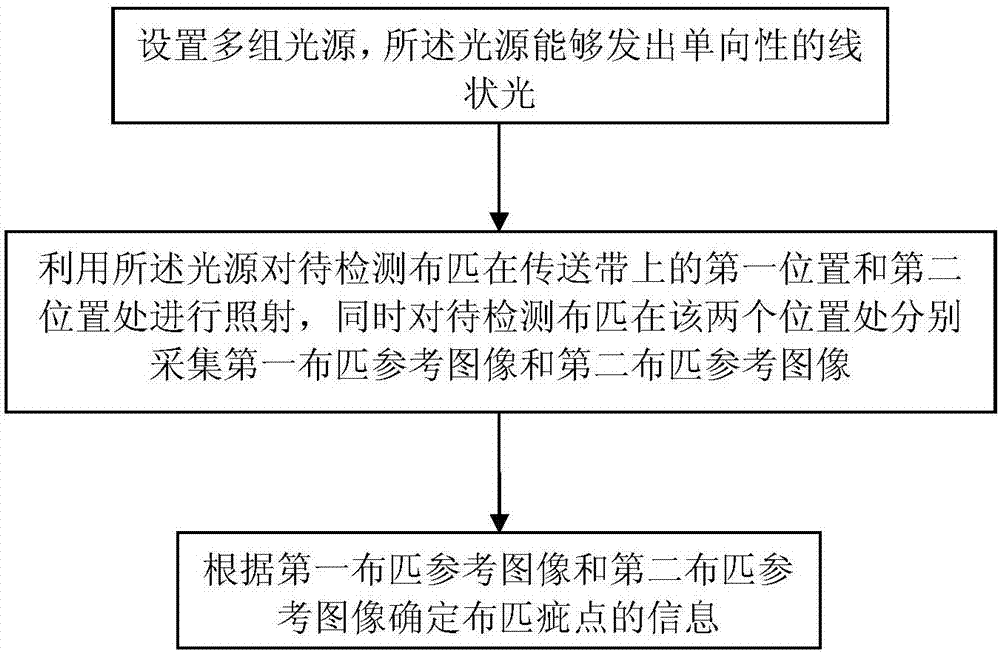

[0045] Such as figure 1 As shown, the present invention provides a kind of real-time detection method of cloth defect, detects the defect protruding from the surface of the cloth to be detected, where the defect to be detected is its surrounding area (the size of the surrounding area depends on the actual pattern of the cloth or the weaving The process is determined, for example, for a cloth that is completely flat and has no convex and concave changes, the area is a defect of 1 mm or more on a circle with a diameter of 1 cm, wherein the cloth to be inspected is conveyed on a conveyor belt, and the method includes:

[0046] (1) Multiple groups of light sources are set, and the light sources can emit unidirectional linear light;

[0047] (2) using the light source to irradiate the cloth to be detected at a first position and a second position on the conveyor belt, and simultaneously collect a first cloth reference image and a second cloth reference image at the two positions of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com