Ultra-low loss and ultra-low temperature OPGW (optical fiber composite overhead ground wire) and production method thereof

An ultra-low optical cable technology, applied in the direction of fiber mechanical structure, etc., can solve problems such as lack, and achieve the effects of good usability, low attenuation loss, and reasonable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

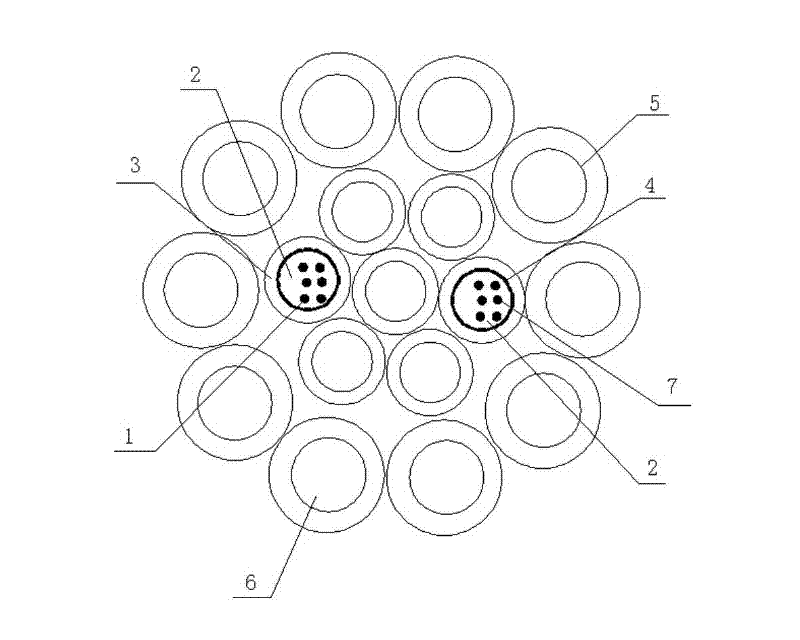

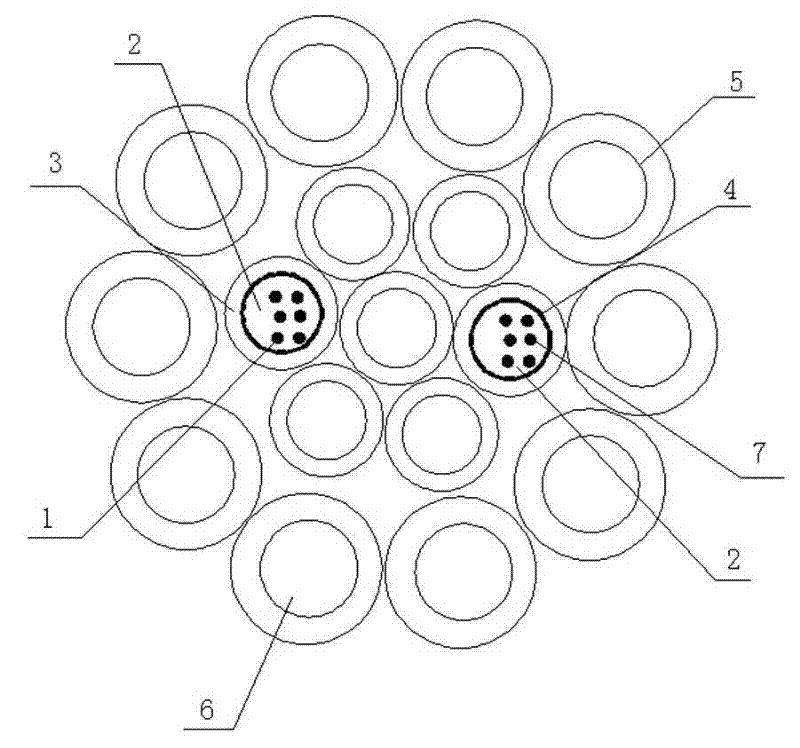

[0033] Refer to attached figure 1 , ultra-low loss, ultra-low temperature OPGW optical cable includes ultra-low loss optical fiber (ULL optical fiber) 1, G652D optical fiber, low-temperature fiber paste 2, first stainless steel tube 3, second stainless steel tube 4, inner high-strength aluminum-clad steel wire 5 and Outer high-strength aluminum-clad steel wire 6. An ultra-low loss optical fiber (ULL optical fiber) 1 is installed in the first stainless steel tube 3, and is uniformly filled with low-temperature fiber paste 2 to form the first stainless steel optical fiber unit, and a G652D optical fiber 7 is installed in the second stainless steel tube 4, and is evenly filled The second stainless steel optical fiber unit is composed of low-temperature fiber paste 2, and the outer diameters of the first stainless steel optical fiber unit and the second stainless steel optical fiber unit are φ2.5˜φ2.7 mm. The first stainless steel optical fiber unit and the second stainless stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com