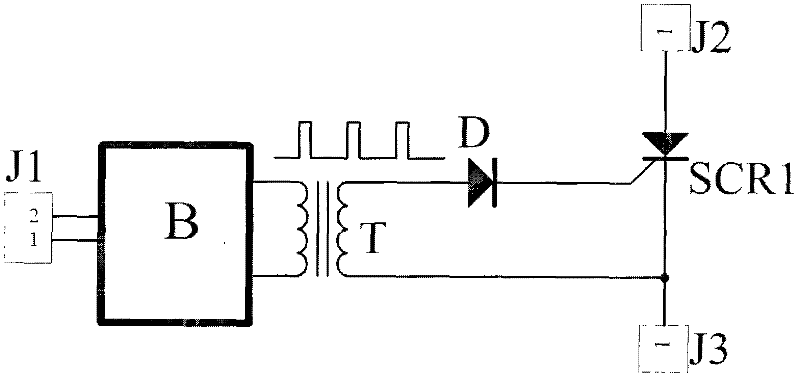

Trigger energy saving apparatus and thyristor switch

An energy-saving device and thyristor technology, applied in electronic switches, electrical components, pulse technology, etc., can solve the problems of poor linearity of thyristor output current waveform, large power supply capacity, and increased volume, and achieve low triggering energy consumption and triggering drive energy consumption. Low, triggers the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

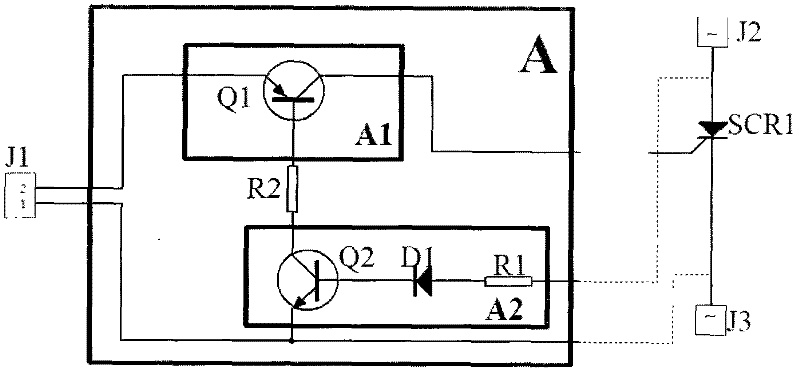

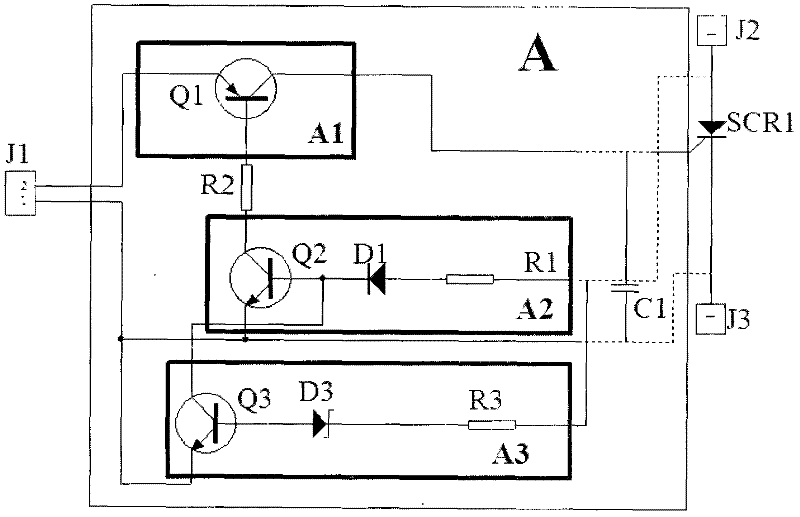

[0028] as attached figure 2 As shown, J1 is the trigger signal input terminal, the input trigger signal is connected to the thyristor SCR1 through the trigger energy-saving device (A), and the trigger energy-saving device (A) includes an electronic switch (A1), a voltage detection circuit (A2), an electronic switch ( A1) connected in series with the trigger circuit of the thyristor SCR1 to be controlled; the input terminal of the voltage detection circuit (A2) is connected to both ends of the thyristor SCR1, and the output terminal of the voltage detection circuit (A2) is connected to the electronic switch (A1) through a current limiting resistor R2 (Note: R2 is a non-essential component, and it can be used when the electronic switch (A1) or the voltage detection circuit (A2) has a built-in current-limiting component, such as transistors Q1 and Q2, which use built-in current-limiting resistors).

[0029] Electronic switch (A1): Built-in transistor Q1 (note: attached figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com