Sheet cutter and belt working apparatus

A technology of processing tools and cutting devices, which is applied in metal processing and other directions, can solve problems such as falling off and dangerous situations, and achieve the effect of safe separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

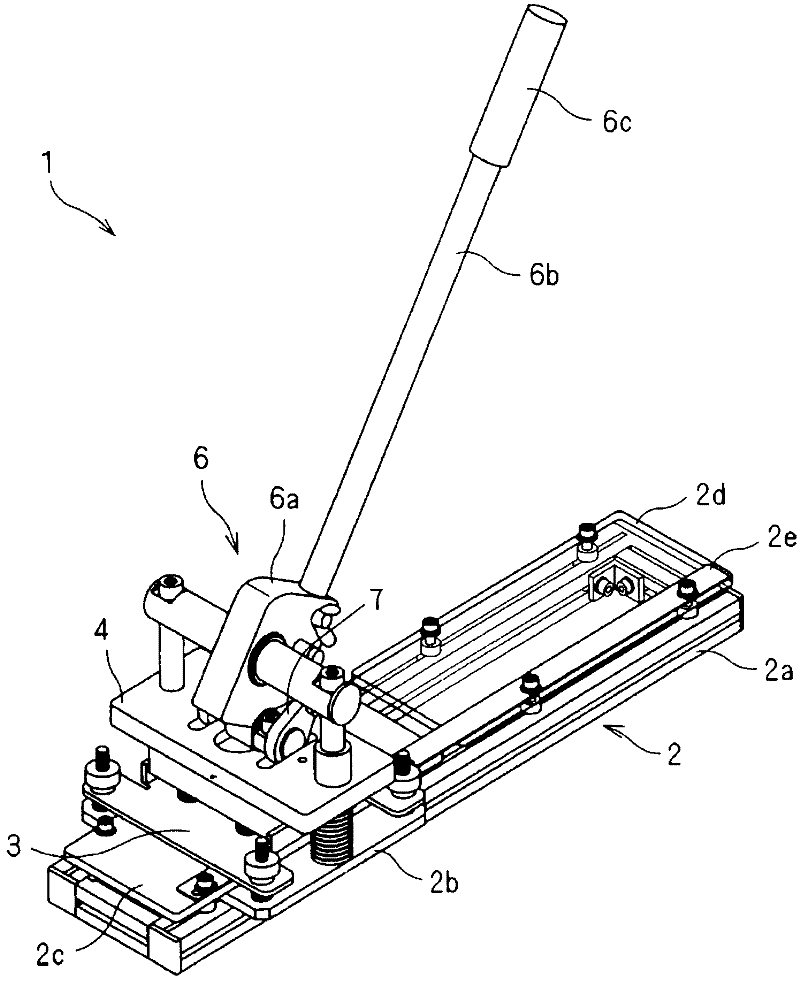

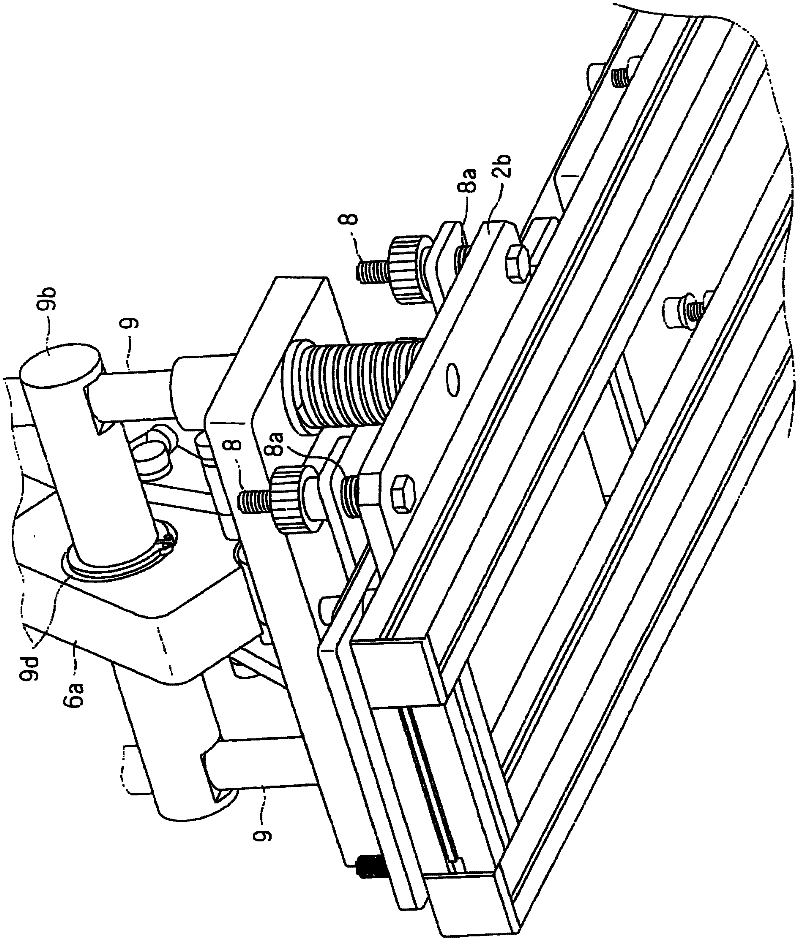

[0024] Hereinafter, a tape processing tool according to an embodiment of the present invention will be described in detail with reference to the drawings. In addition, although the cutting object of the sheet|seat cutting apparatus of this invention is a sheet, it is substantially the same as a tape processing tool.

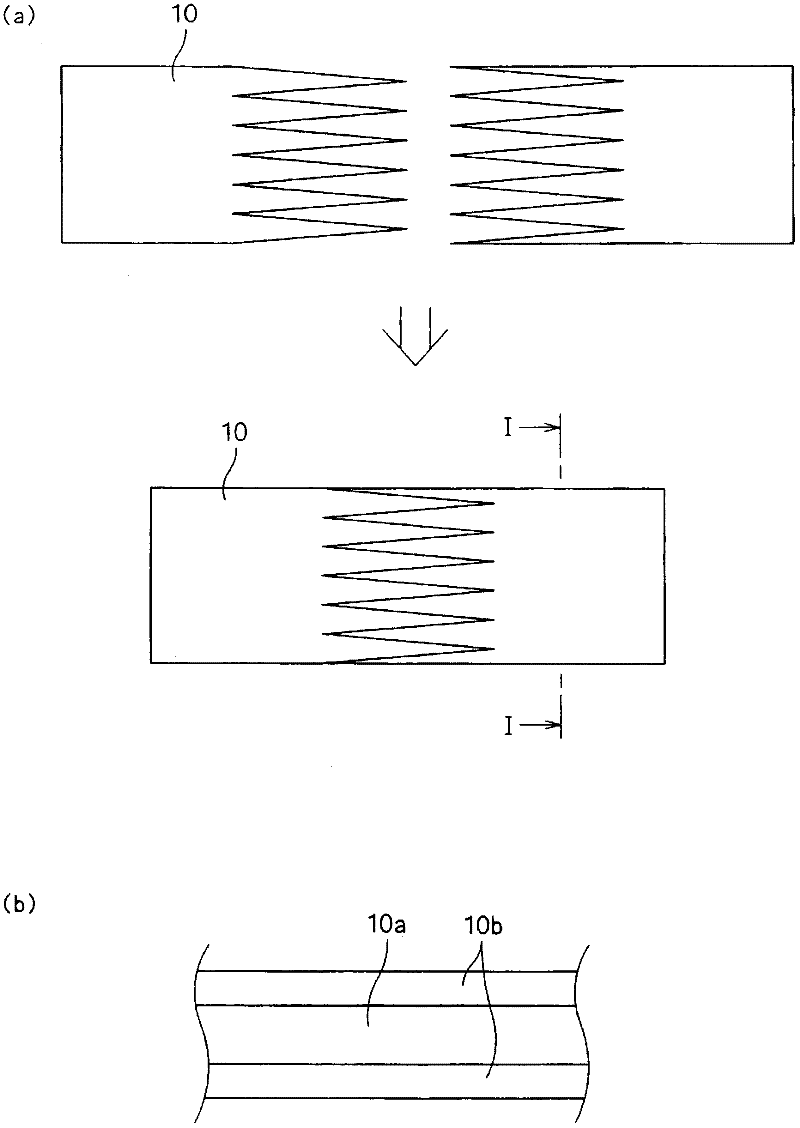

[0025] First, refer to figure 2 (a) and (b) illustrate the tape 10 cut by the tape processing tool of the present invention.

[0026] figure 2 The belt 10 shown in (a) and (b) is a long sheet with a predetermined width, and is specifically a belt used for conveying apparatuses, such as a belt conveyor and a printing machine. like figure 2 As shown in (b), the belt 10 is composed of a core material 10a and outer layers 20b laminated on both surfaces of the core material 10a. The core material 10a is formed of canvas, non-woven fabric, etc., and the outer layer 10b is formed of natural rubber, various synthetic rubbers, or thermoplastic elastomers or thermoplas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com