Sputtering device and sputtering method

A sputtering, sputtering gas technology, used in sputtering, ion implantation, vacuum evaporation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

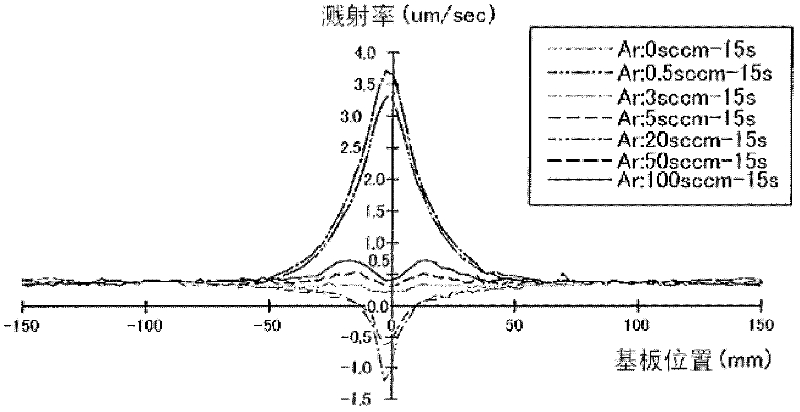

Examples

Embodiment Construction

[0028] Embodiment of the invention

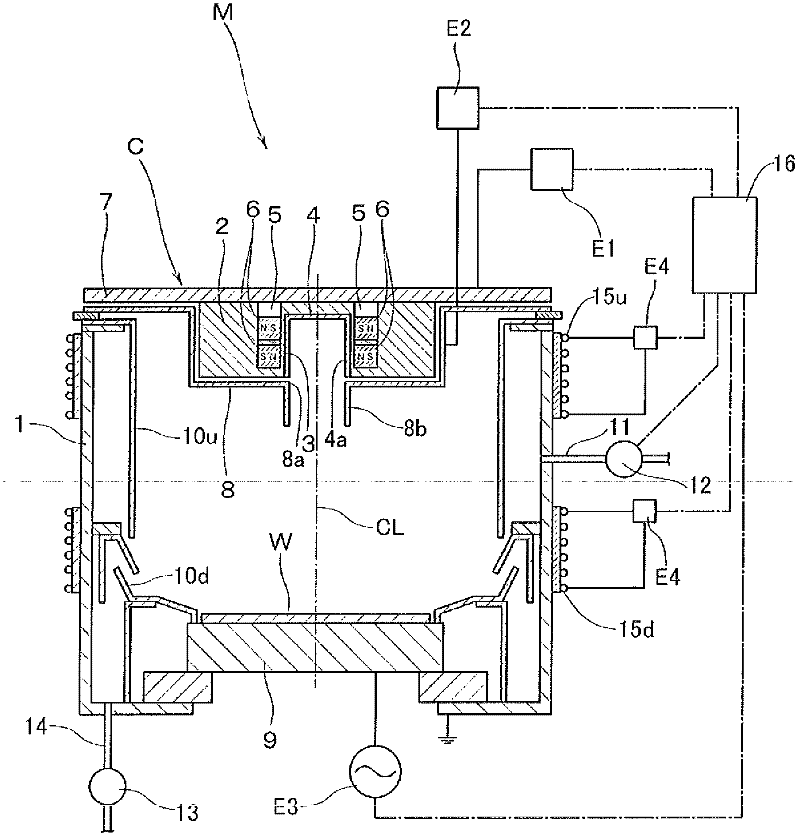

[0029] Hereinafter, with reference to the drawings, a sputtering apparatus having a cathode unit in an embodiment of the present invention will be described. Such as figure 1 As shown, the sputtering device M has a vacuum chamber 1 that can form a vacuum gas environment, and the top of the vacuum chamber 1 is equipped with a cathode unit C. In addition, in the following description, the top side of the vacuum chamber 1 is referred to as "upper", and the bottom side thereof is referred to as "lower" for description.

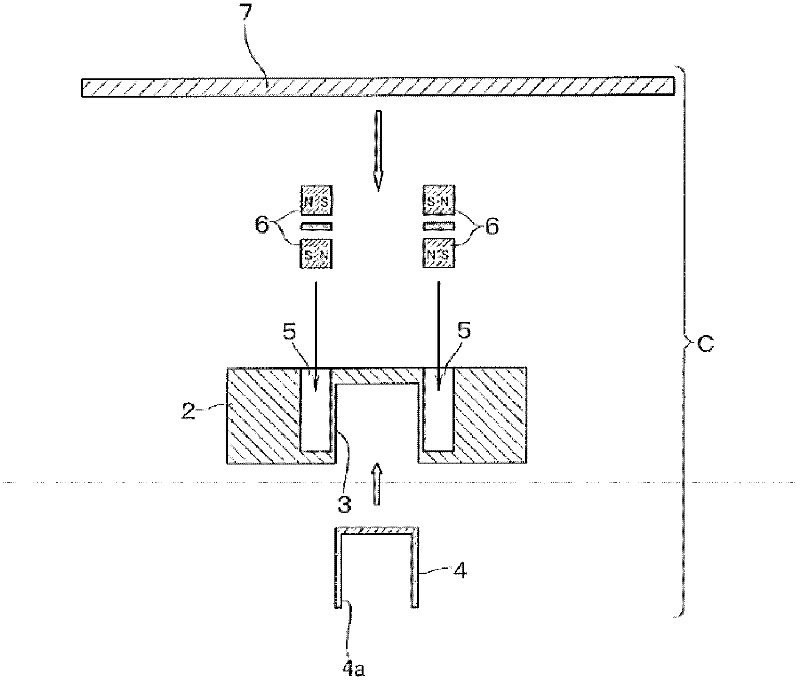

[0030] Such as figure 2 As shown, the cathode unit C has a cylindrical bracket 2 made of a conductive material, for example, the same material as the target material described later. A recess 3 is formed in the center of the lower surface of the bracket 2. The opening area of the recess is set as The target 4 is inserted into the recess 3 within the range of

[0031] The target 4 selects a suitable material according to the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com