Quartz sand filter and air-water backwashing method thereof

A quartz sand filter, filter technology, applied in gravity filters, chemical instruments and methods, loose filter material filters, etc. The effect of saving backwash water consumption, effective and thorough cleaning, and less backwash water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

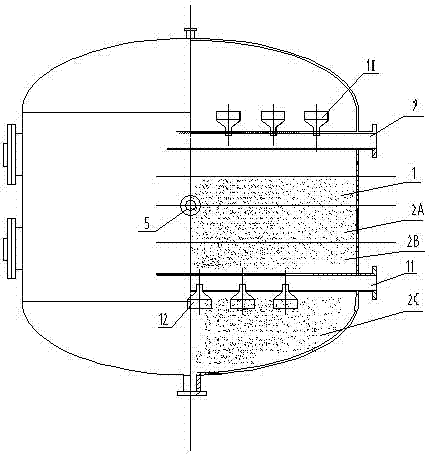

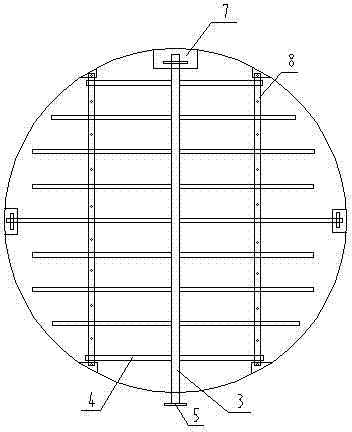

[0028] This embodiment is a quartz sand filter with a structure such as figure 1 and figure 2 As shown, the filter is provided with a quartz sand layer inside, and the quartz sand layer is the filter layer 1, the first supporting layer 2A, the second supporting layer 2B and the third supporting layer 2C from top to bottom, and the filter cartridge A water inlet pipe is arranged above the filter layer 1 at the top of the body, and a water outlet pipe is arranged in the support layer at the bottom of the filter cylinder body. A layer of air intake pipe is provided at the interface between the filter layer 1 and the first supporting layer 2A inside the quartz sand filter. The air intake pipe is composed of the main air intake pipe 3 and the auxiliary air pipe 4 connected to the main air intake pipe 3. The main air intake pipe 3 An air inlet 5 is provided on the outer wall of the quartz sand filter, and an air outlet 6 is opened on the auxiliary air pipe 4 . The main air intake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com