Omnibearing automatic welding device

An automatic welding, all-round technology, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of non-dense connection, underfill, undercut, etc., and achieve the effect of improving welding speed and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

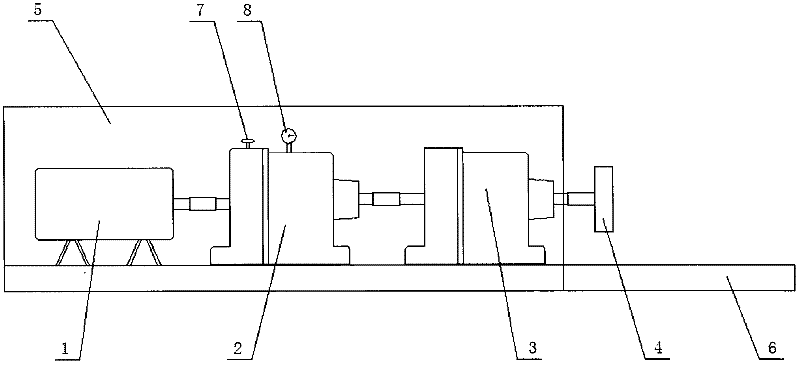

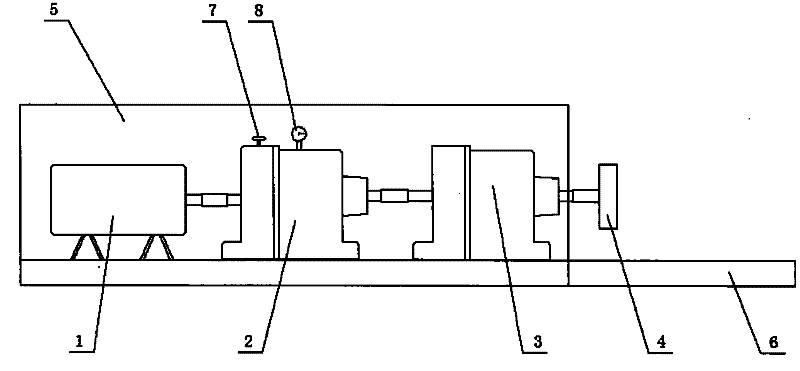

[0013] An all-round automatic welding equipment, including a motor 1, a transmission shaft, a gear-type adjustable reducer 2, and a turbine-type speed-adjustable reducer 3. One end of the motor 1 is connected with a power switch, and the motor 1 is connected to the gear-type adjustable reducer through the connecting shaft. The adjustable speed reducer 2 is connected; the gear type adjustable speed reducer 2 is connected to the turbine type speed control reducer 3, its speed is 20-800r / min, and there is a fixture 4 behind the turbine type speed control reducer 3, the connection method for horizontal connections;

[0014] A rectangular workbench 5 is provided outside the motor 1, the gear-type reducer 2 and the turbine-type speed-regulating reducer 3, and the motor 1, the gear-type adjustable reducer 2, and the turbine-type speed-regulating reducer 3 are arranged inside the workbench 5, Protect the safety of the machine and staff; there is a protruding table at the bottom of the...

specific Embodiment 2

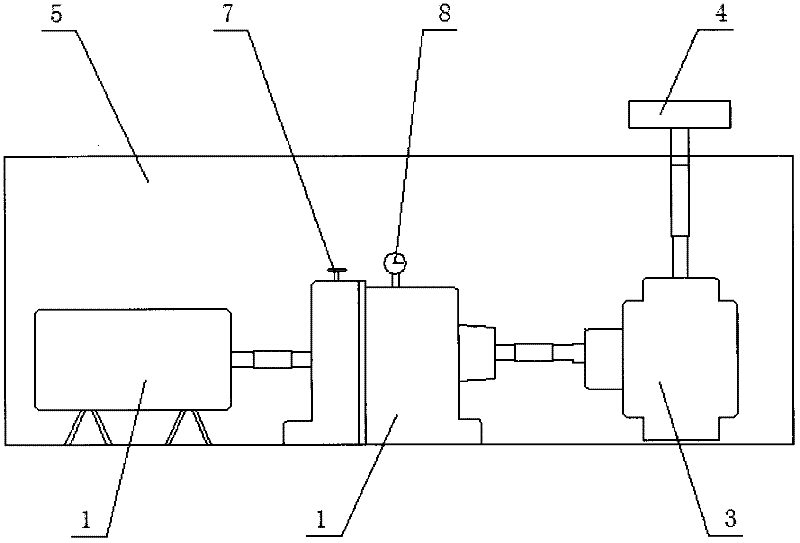

[0017] An all-round automatic welding equipment, including a motor 1, a transmission shaft, a gear-type adjustable reducer 2, and a turbine-type speed-adjustable reducer 3. One end of the motor 1 is connected with a power switch, and the motor 1 is connected to the gear-type adjustable reducer through the drive shaft. The adjustable speed reducer 2 is connected; the gear type adjustable speed reducer 2 is connected to the turbine type speed control reducer 3, its speed is 20-800r / min, and there is a fixture 4 behind the turbine type speed control reducer 3, the connection method for vertical connection;

[0018] There is a rectangular workbench 5 outside the motor 1, the gear-type adjustable reducer 2 and the turbine-type speed-adjustable reducer 3, and the motor 1, the gear-type adjustable reducer 2, and the turbine-type speed-adjustable reducer 3 are arranged on the workbench 5 Inside, it protects the safety of the machine and workers; the top of the rectangular workbench is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com