Novel grinder workbench

A workbench and grinding machine technology, which is applied in the direction of grinding machines, grinding machine parts, machine tools suitable for grinding workpiece planes, etc., can solve problems such as poor flexibility, achieve improved safety, better working results, and improved cleaning efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

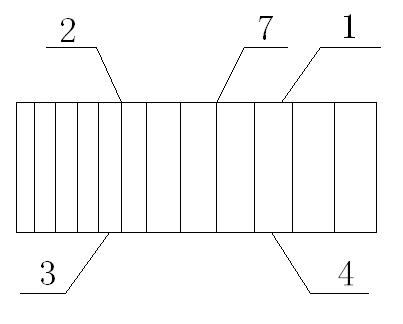

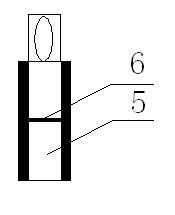

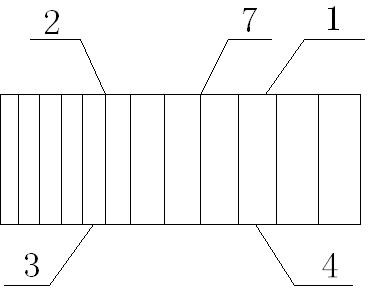

[0010] Such as figure 1 , a new type of grinder workbench, comprising a bracket suction cup 1 and a high-efficiency cleaning brush 5, one end of the bracket suction cup 1 is equipped with a high-efficiency cleaning brush 5, a magnetic strip 1 2 and a magnetic strip 2 7 are laid on the bracket suction cup 1, the magnetic Strip one 2 is thinner than magnetic strip two 7, and high-efficiency cleaning brush 5 is provided with telescopic joint 6 in the middle. The first magnetic strip 2 and the second magnetic strip 7 can be adjusted at will, only the inner core needs to be programmed in advance. The magnetic strips of the present invention are thick and dense. After power-on, the magnetic strips have strong or weak suction, and different fixed intervals can be produced. The small workpiece grinding area 3 and the wide tool grinding area 4 can be selectively placed in different Specification workpieces are ground.

[0011] Such as figure 2 , cooperate with the flat high-efficie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com