Anti-counterfeiting stamp and machining method thereof

A seal and imprint technology, which is applied in the field of anti-counterfeiting seals and their processing, can solve the problems that the seal is not easy to compare, the amount of anti-counterfeiting information is low, and the pattern of the seal is easy to imitate, so as to achieve easy cracking, less anti-counterfeiting information, and safety. low sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

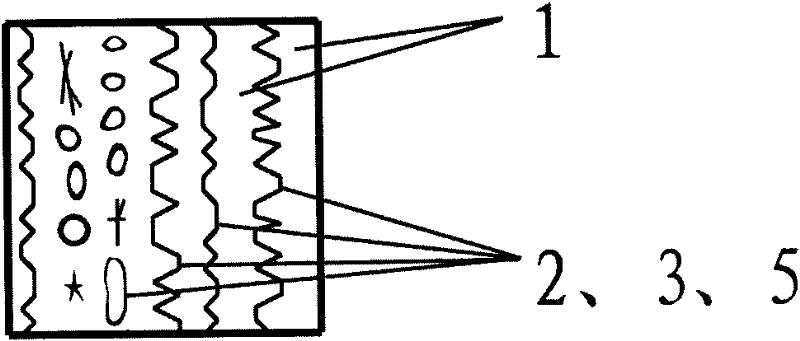

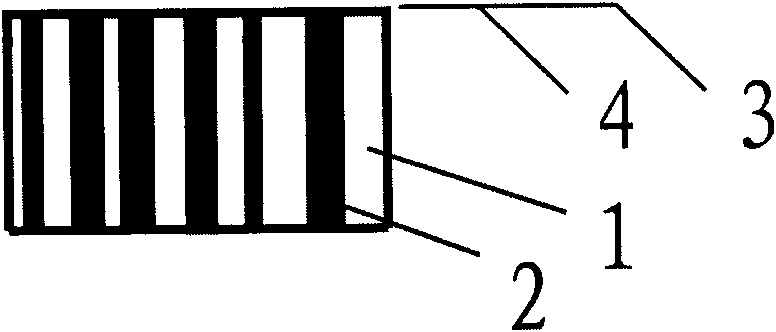

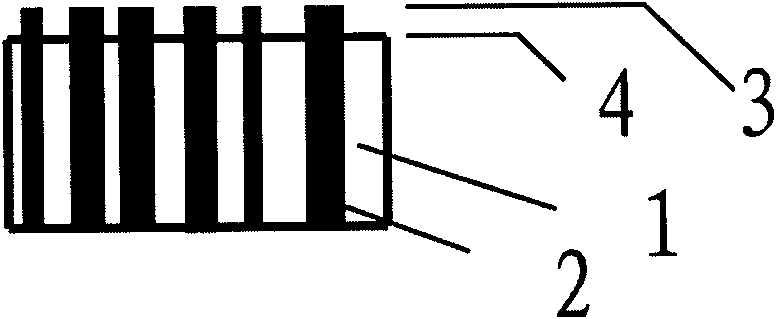

[0026] Embodiment one sees appendix figure 1 , 2 , 3, 4, 5, the printing material (2) is 0.025 mm ~ 0.3 mm thick titanium alloy foil and 0.25 mm thick stainless steel capillary through mechanical rolling and surface treatment, and the PVC sheet and the printing material ( 2) Carry out vacuum hot-melt compounding, use a hot air welding torch to melt and remove the base material (1) PVC with poor heat resistance close to the end surface of the base material (4), and remove the printed material (2), so that The end surface (3) of the printed material is higher than the end surface (4) of the substrate, and the end surface (3) of the printed material forms a printed pattern (5), thereby obtaining an anti-counterfeit seal. The anti-counterfeit seal is bonded together with the ordinary seal body (6), so that the height of the end surface (7) of the ordinary seal is lower than the end surface (3) of the printing material, and a combined anti-counterfeit seal is obtained.

Embodiment 2

[0027] Embodiment two sees attached figure 1 , 2 3. Put the substrate (1) PMMA sheet and the printed material (2) 0.025 mm to 0.3 mm thick stainless steel foil into vacuum hot-melt composite, divide the composite material with chloroform to close the end surface of the substrate (4) The base material (1) PMMA is dissolved and removed, while the stamping material (2) stainless steel foil is retained, and the end face of the stamping material (3) constitutes the stamping (5), thereby obtaining an anti-counterfeit seal.

Embodiment 3

[0028] Embodiment three sees attached figure 1 , 2 3. The printing material (2) is stainless steel foil with a thickness of 0.025 mm to 0.3 mm and a stainless steel capillary with a thickness of 0.25 mm. Put the substrate (1) cement or uncured phenolic resin in a small container, and place the Insert the material (2) stainless steel foil and capillary, directly make the printing material (2) slightly higher than the surface of the substrate (1), and beat and vibrate the small container to make the substrate (1) settle, manually remove the end surface of the printing material (2) (3) the substrate (1), the substrate (1) is solidified, and the end surface (3) of the printed material forms the printed pattern (5), thereby obtaining the anti-counterfeit seal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com