Industrial production device for thermosetting resin coated controlled-release fertilizer

A production device and resin coating technology, applied in fertilization devices, applications, agriculture, etc., can solve the problems of low heat utilization rate, slow curing time, low production efficiency, etc., to improve heat utilization rate, high production effect, heat low damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

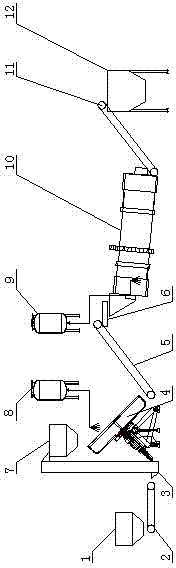

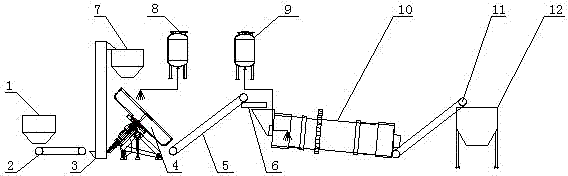

[0016] like figure 1 As shown, an industrialized production device for thermosetting resin-coated controlled-release fertilizer includes a preheating device 1. The preheating device 1 can use a vibrating fluidized bed for preheating or a silo with a heating coil. The outlet of the preheating device 1 is equipped with an electronic weighing scale 2 and a belt conveyor. The end of the belt conveyor is connected to the elevator 3, and the outlet of the elevator 3 is connected to the entrance of the heating bin 7. The outlet of the heating bin 7 is equipped with a direct heating disc 4 for direct heating. The outlet of the disk 4 enters the heating drum 10 through the conveyor belt 5 and the screening machine 6, and the outlet of the heating drum 10 is connected to the finished product bin 12 through the finished product belt conveyor 11.

[0017] The production device includes a resin metering and spraying device 8 and a curing agent metering and spraying device 9, the nozzle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com