Plate implanted body node aluminum alloy space truss structure

A space truss and aluminum alloy technology, which is applied to truss structures, truss bridges, truss beams, etc., can solve the problems of undiscovered aluminum alloy space truss structures, achieve reasonable force, good formability, and improve earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further described below in conjunction with accompanying drawing.

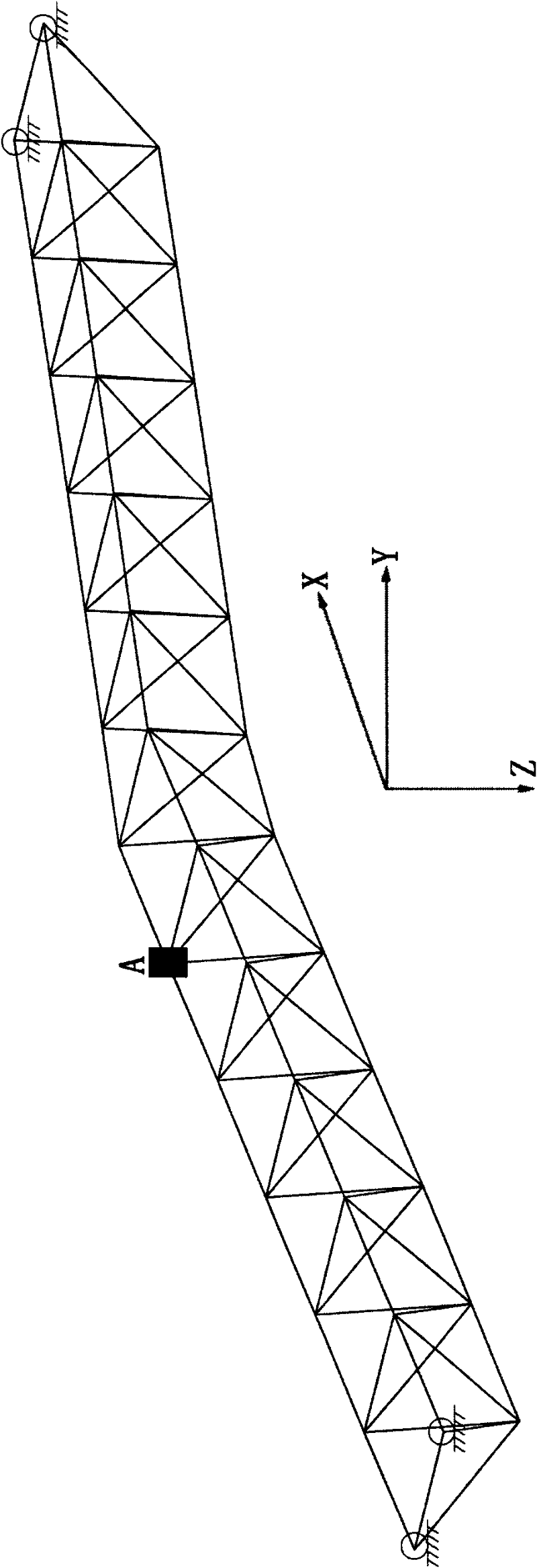

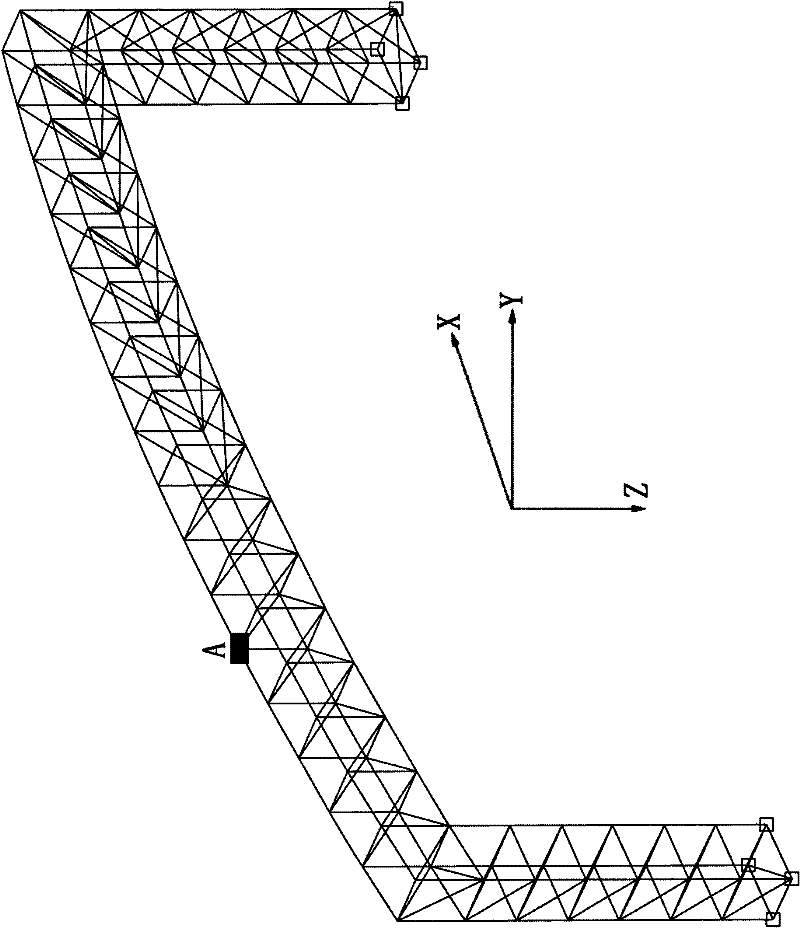

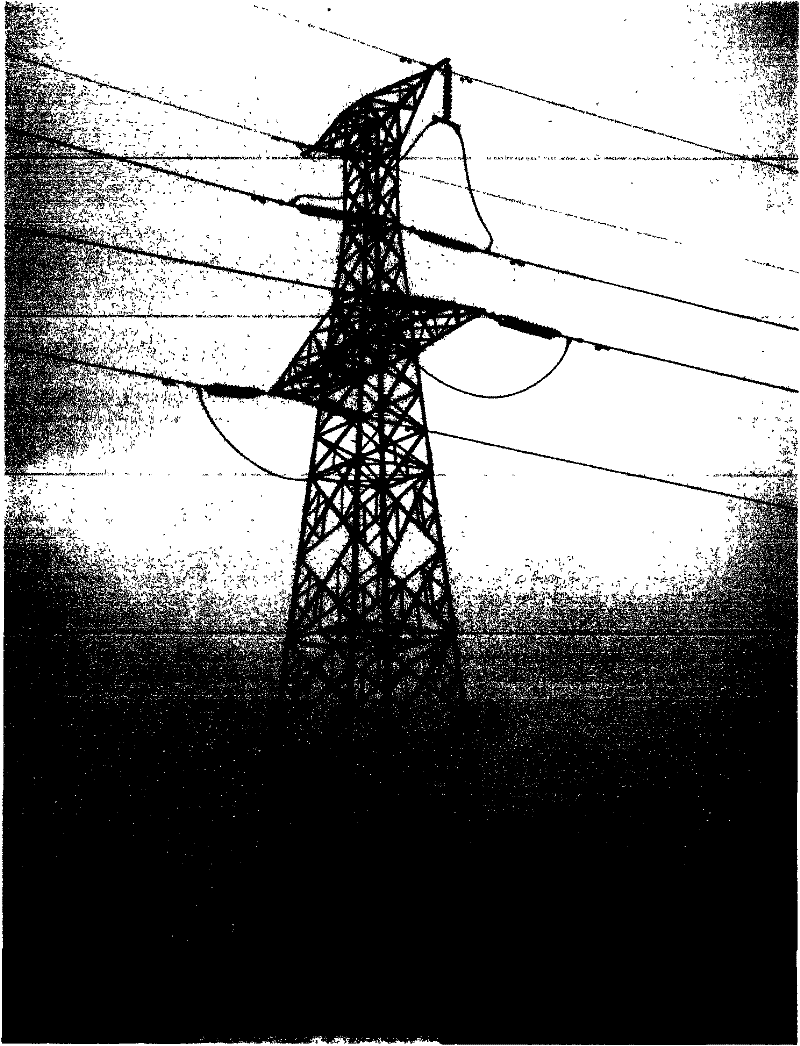

[0030] Figure 1 and Figure 2 are the plate-planted body-node aluminum alloy space truss structures composed according to the rule of "three non-coplanar chain rods fix the space and one new node", and all the node bodies and all the rods are made of aluminum alloy made. Its span can be large or small, and it is often used in large-span factory buildings, exhibition halls, gymnasiums, bridge projects and tower projects.

[0031] It can be seen from Figure 4 that each rod end of all the rods of the space truss has an opening for the implantation of the limb plate of the node body. The node body (1) is provided with a limb board U(5) in the X(2) direction of the truss, a limb board V(6) in the Y(3) direction, and a limb board W in the Z(4) direction (7), a total of three limbs. The U(5) direction limb plate on the node body is implanted in the X(2) direction on the truss to meet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com