High pressure valve and control method

A technology for high-pressure valves and valve seats, applied in valve details, valve devices, valve operation/release devices, etc., can solve problems such as large energy consumption, and achieve the effect of avoiding thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

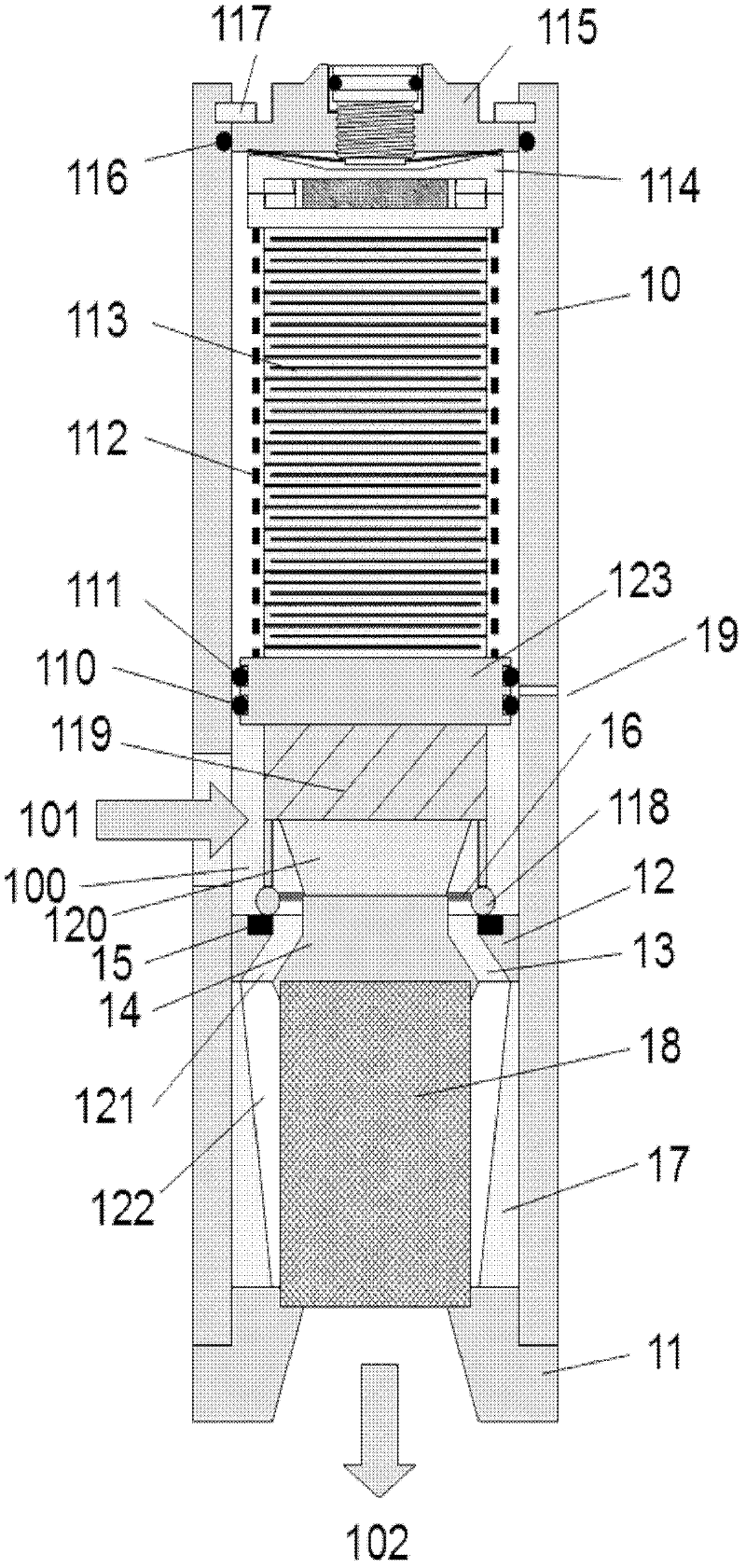

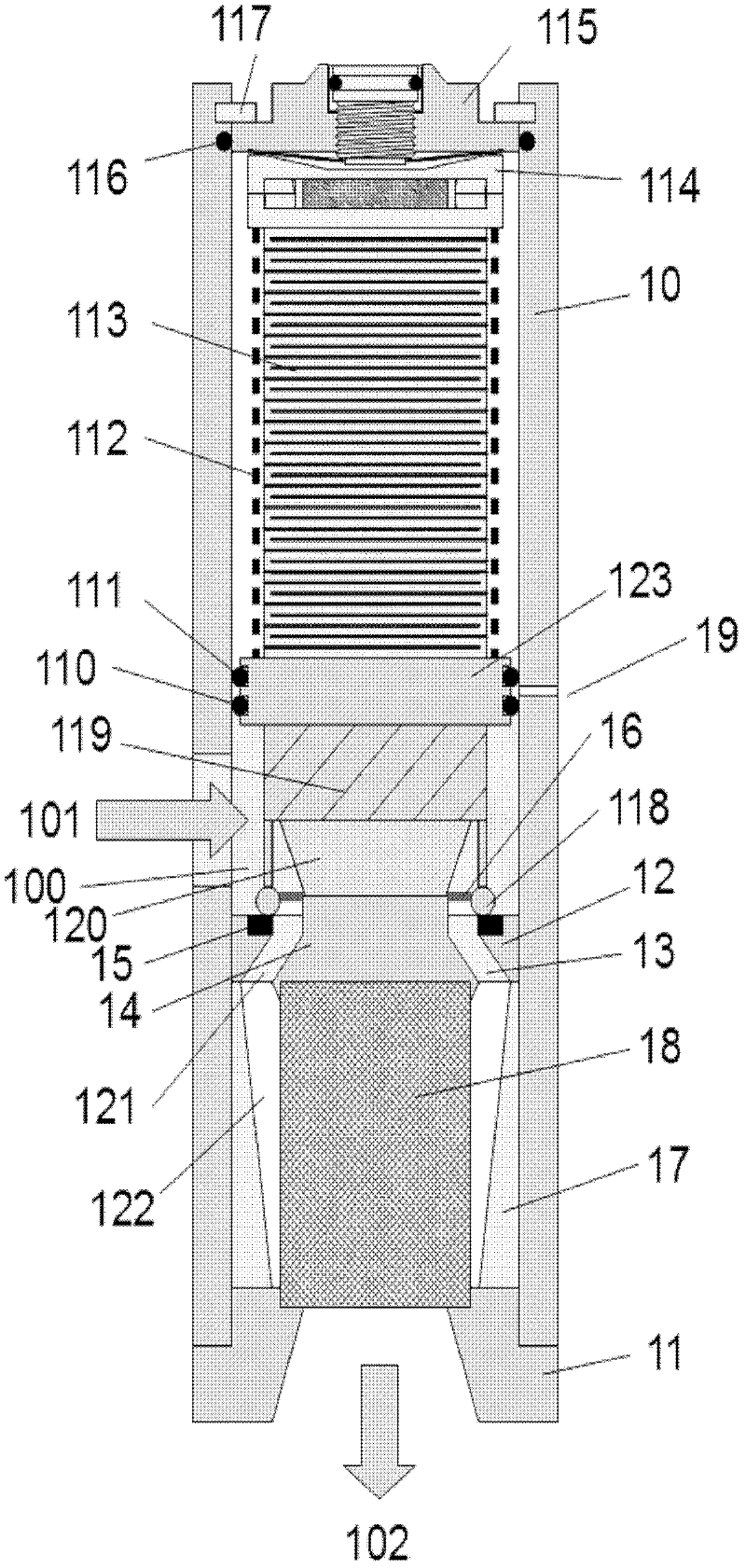

[0023] figure 1 is a schematic diagram of one embodiment of a piezo-controlled high pressure valve, externally comprising a conduit 10 having an inlet conduit 101 , an outlet conduit 102 and a fine adjustment screw 50 on a mechanical fine adjustment element 115 . Inside the pipeline 10 , it includes a mechanical precision adjustment element, a mechanical thermal expansion element 114 , a piezoelectric actuator 113 , a pretensioned pipeline 112 , a buffer disk 123 , a connecting and unloading amplifier 119 , and a valve structure 118 . The valve seat 115 and the flow measuring net 18 surround in series. The mechanical fine adjustment element 115 is secured to the pipe 10 by a spring ring 117 and sealed by a surrounding O-ring 116 . The buffer disk 123 is located between the piezoelectric actuator 113 and the high pressure chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com