Method and product for two-phase flow heat exchange and heat collection in vacuum heat-collecting pipes

A vacuum heat collecting tube and heat collecting tube technology, which is applied to solar heat collectors, solar heat collectors using working fluid, heating devices, etc. , the effect of less heat exchange links and short suction distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

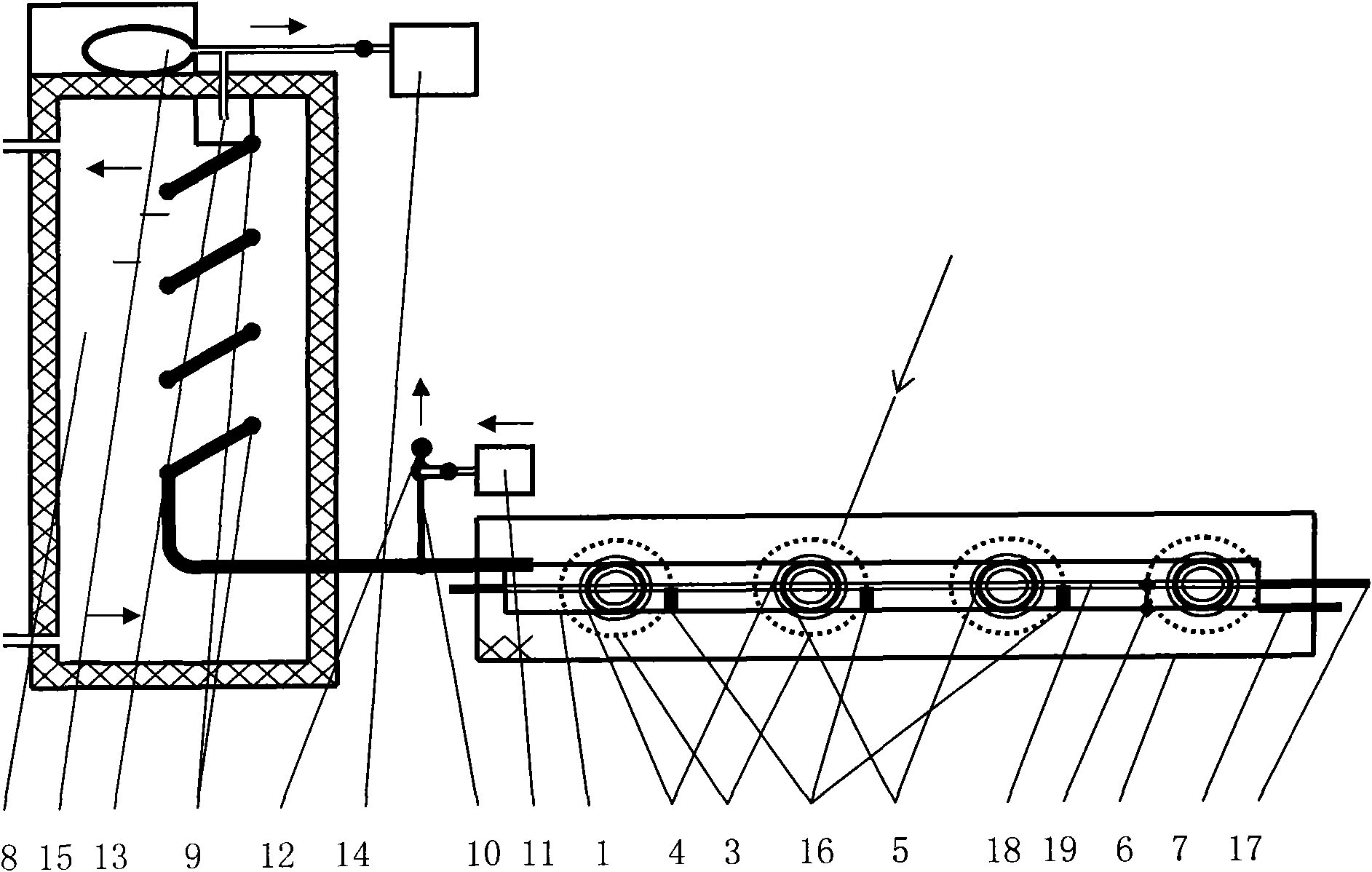

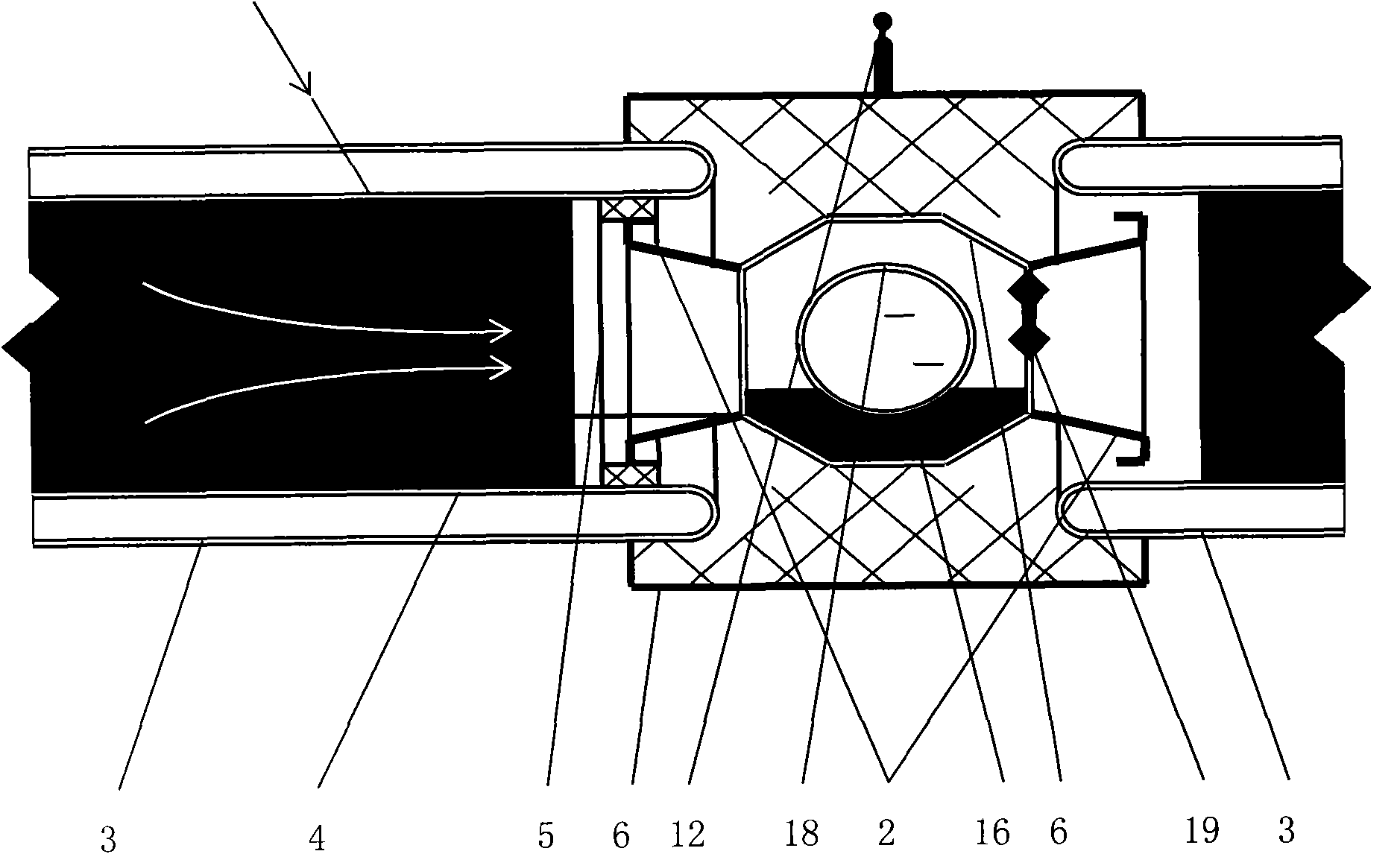

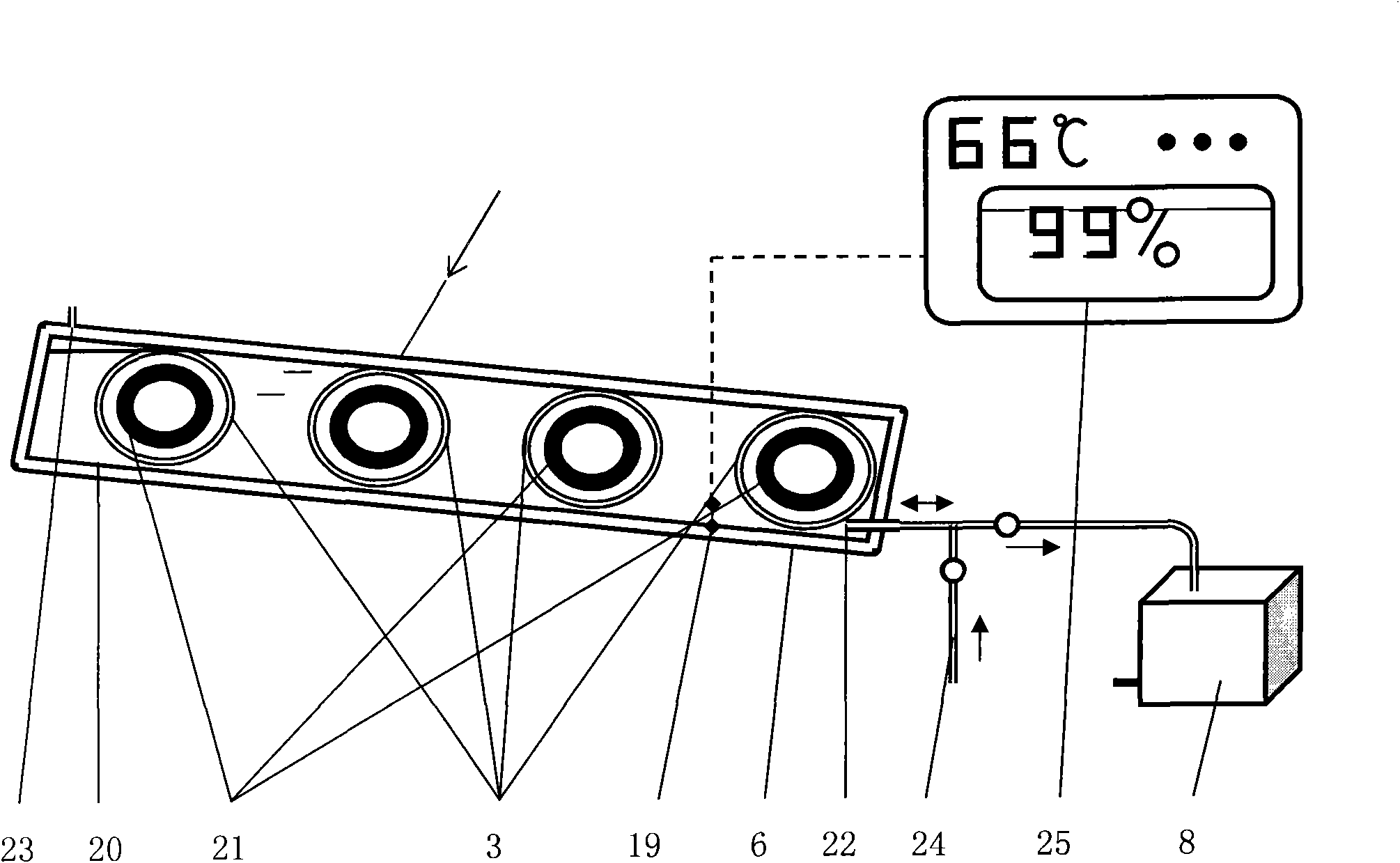

[0029] figure 1 with figure 2 A first embodiment of the present invention is collectively given. figure 1 with figure 2 Among them, two rows of trumpet-shaped connecting barges 2 are welded on both sides of the united main pipe 1, and the port of the barge 2 has a flanging, and the flanging of the barge 2 is connected with the glass tube 4 in the heat collecting tube 3 with a sealing ring 5 to form a A heat collection device for two-phase flow heat exchange in a vacuum heat collection tube. The union main pipe 1 is provided with a casing 6, and the casing 6 is filled with heat insulating material. One end of the united main pipe 1 is connected with a drainage barge 7; the other end protrudes and communicates with the cold end 9 of the two-phase flow heat exchange coil in the heat storage tank 8, and communicates with the external water source 11 and the drain through the water supply barge 10. The pressure valve 12 is connected. The top of the cold end 9 communicates wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com