Method for determining anti-clogging performance of porous asphalt mixture

A technology of asphalt mixture and measurement method, which is applied in the direction of suspension and porous material analysis, measuring device, material inspection product, etc., can solve the problems of optimizing anti-clogging performance, good porous asphalt mixture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

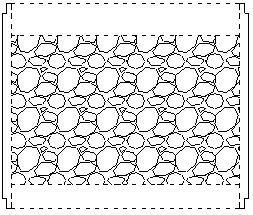

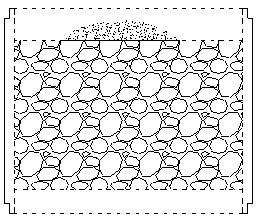

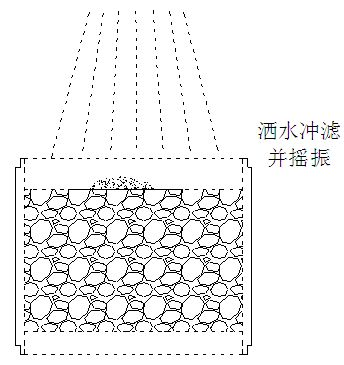

[0022] According to the technical scheme of the present invention, this embodiment provides a method for measuring the anti-clogging performance of porous asphalt mixture. The method first forms a standard Marshall test piece according to the compaction method, without demoulding, and first adopts a corresponding water permeability coefficient measuring device. Measure the water permeability coefficient (initial water permeability coefficient) of the porous asphalt mixture specimen, and then evenly spread a certain quality and a certain gradation of fine material on the surface of the specimen, shake and evenly spray a certain amount of water for flushing, and then measure the water permeability again. Water seepage coefficient (residual water seepage coefficient) of the specimen after filtration. The ratio of residual water permeability coefficient to initial water permeability coefficient (residual water permeability) can be calculated, and the anti-clogging performance of po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com