Power automatic conversion connection system of tyre crane with double power supplies

An automatic conversion and tire crane technology, applied in the direction of circuits, connections, collectors, etc., can solve problems such as low efficiency, potential safety hazards, and high labor intensity, and achieve the effects of improving reliability, avoiding adverse effects, and facilitating transfer operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

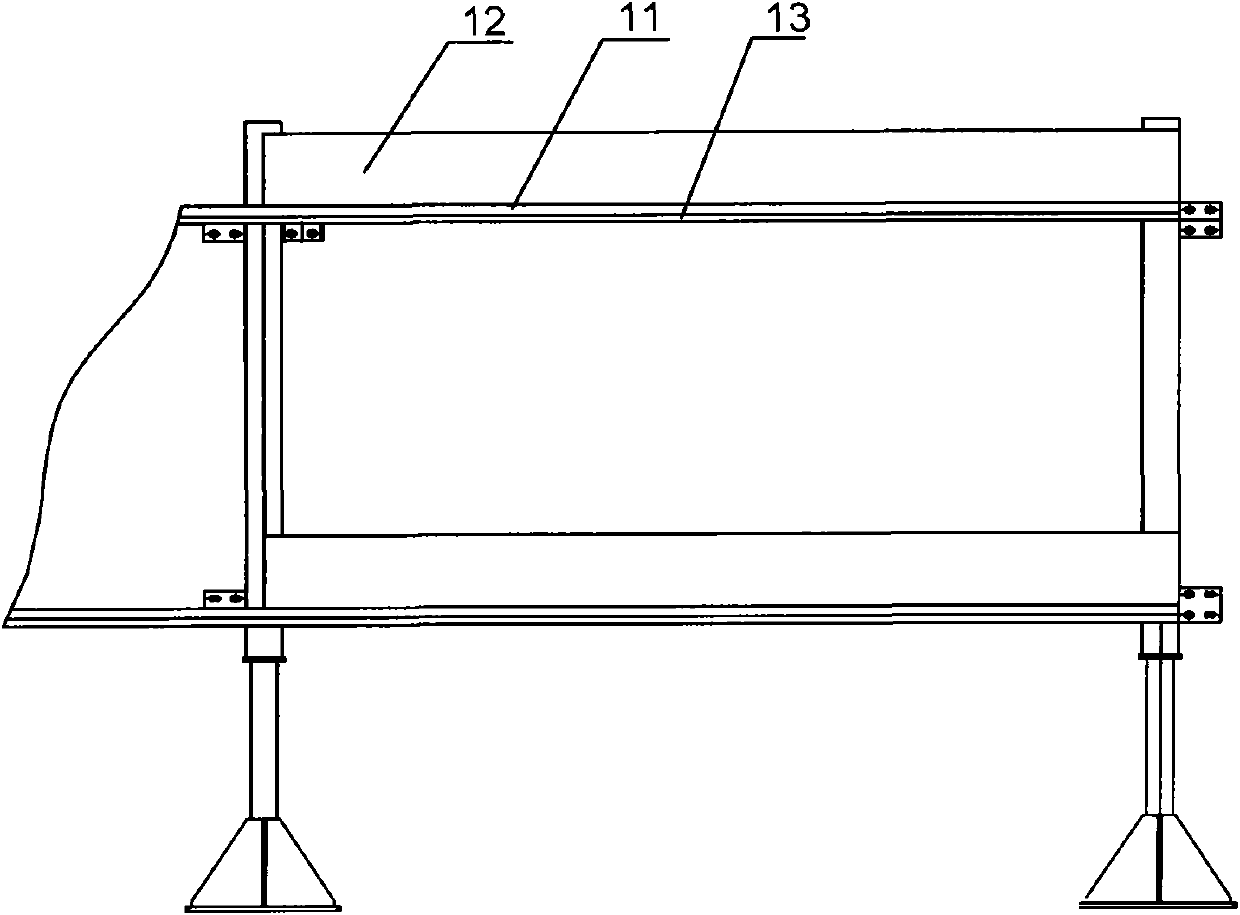

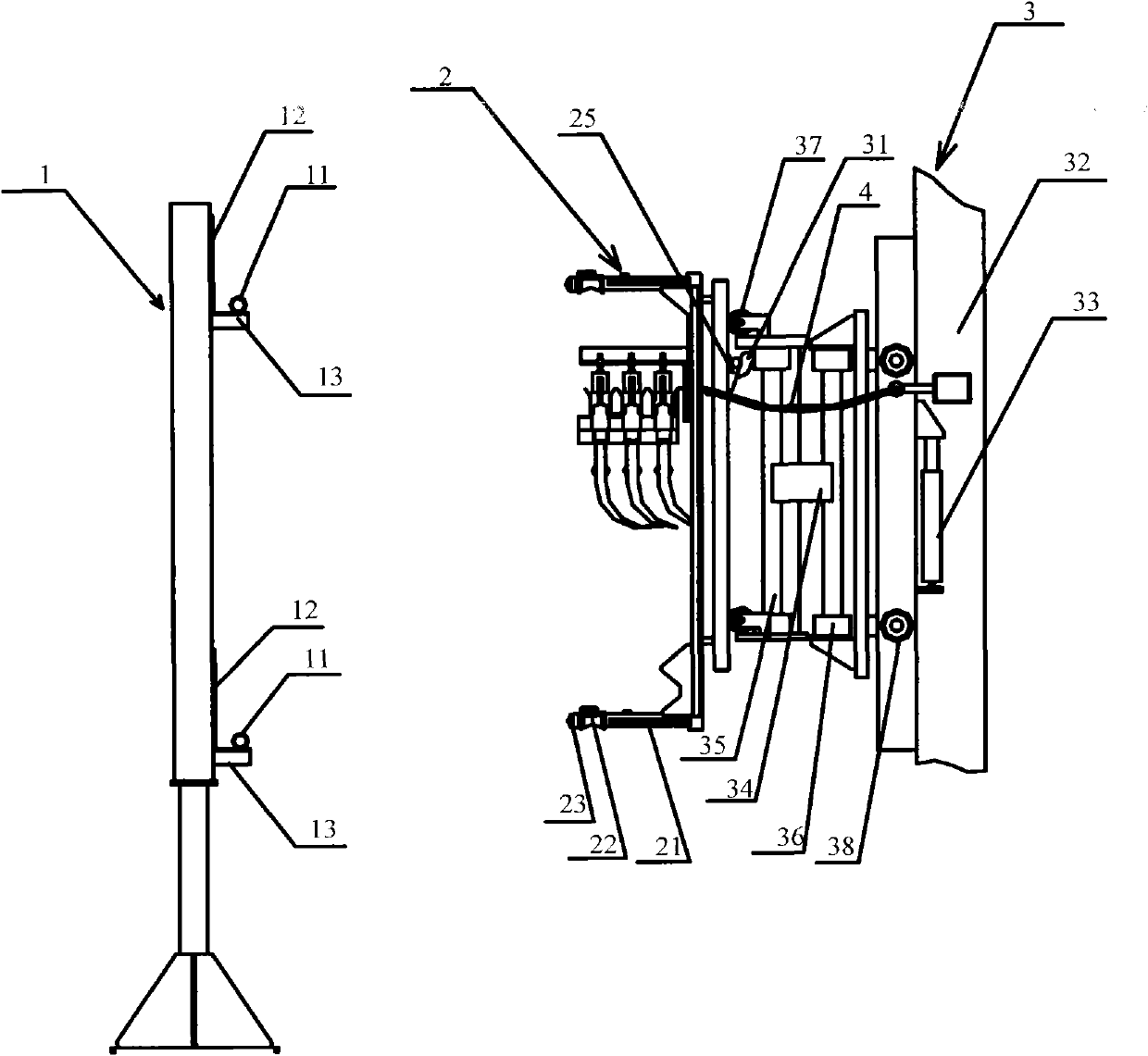

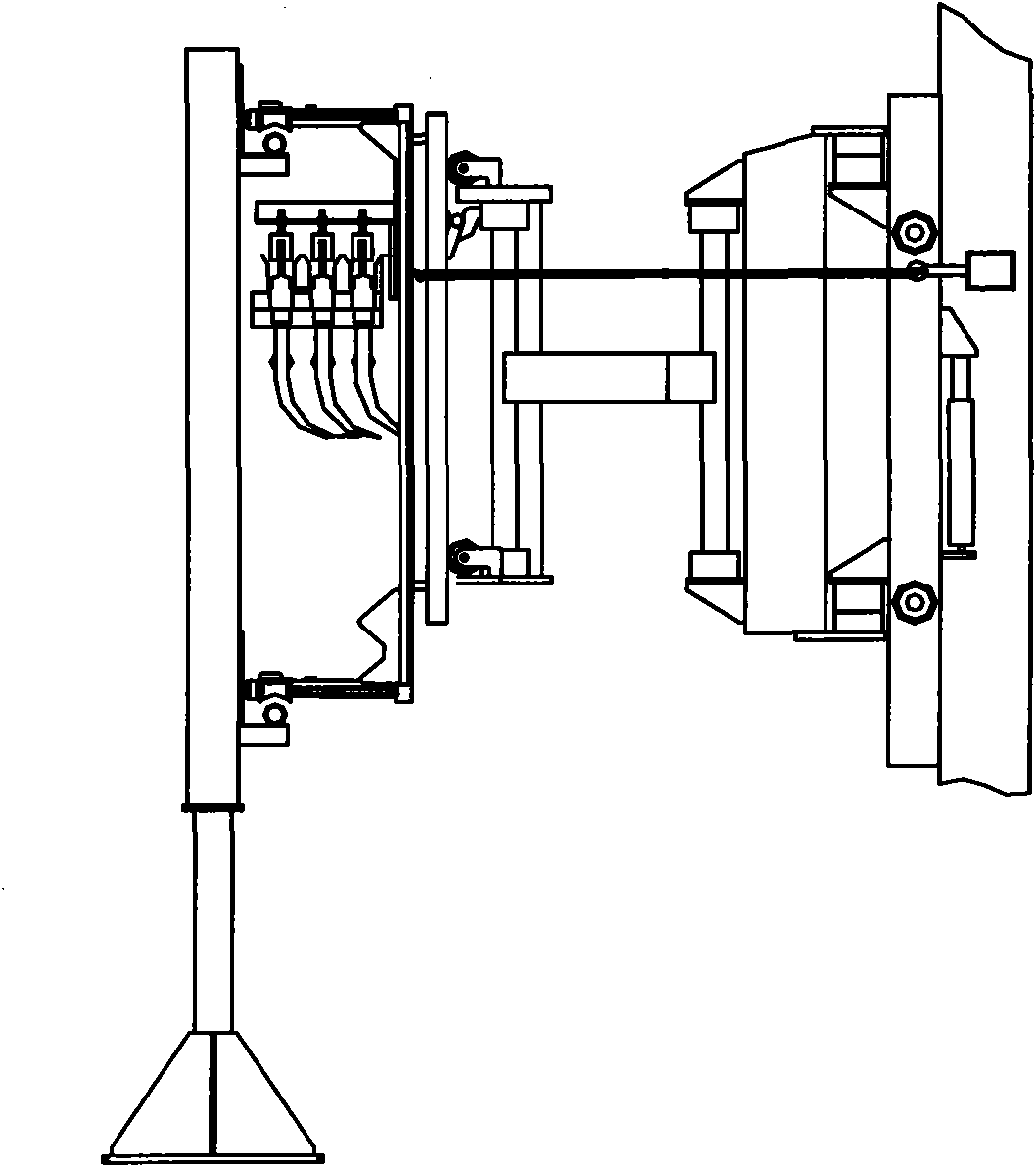

[0026] Embodiment one, see figure 1 As shown, the power automatic conversion and connection system of the dual power supply tire crane in this embodiment improves the structure of the existing trolley wire support 1 and the current collector trolley 2, and installs it on the tire crane equipped with a diesel generator set. The connection mechanism 3 cooperates with the design and realization together. Wherein, a guide rail 11 for supporting the walking of the current collecting trolley 2, a guide rail supporting plate 13 for supporting the guide rail 11, and a guide plate for positioning the horizontal movement of the current collecting trolley are installed on the trolley line support 1 12. combine figure 1 , figure 2 shown. In this embodiment, the guide rail 11 can be realized by using a circular conduit. Preferably, two upper and lower guide rails 11 are installed in parallel on the trolley wire support 1, and a guide rail supporting plate 13 is installed under each gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com