Plasma processing device and method

A plasma and processing device technology, which is applied in the fields of plasma, semiconductor/solid-state device manufacturing, discharge tubes, etc., can solve the problem that the etching selectivity ratio of Low-k film and SiC layer cannot be fully ensured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

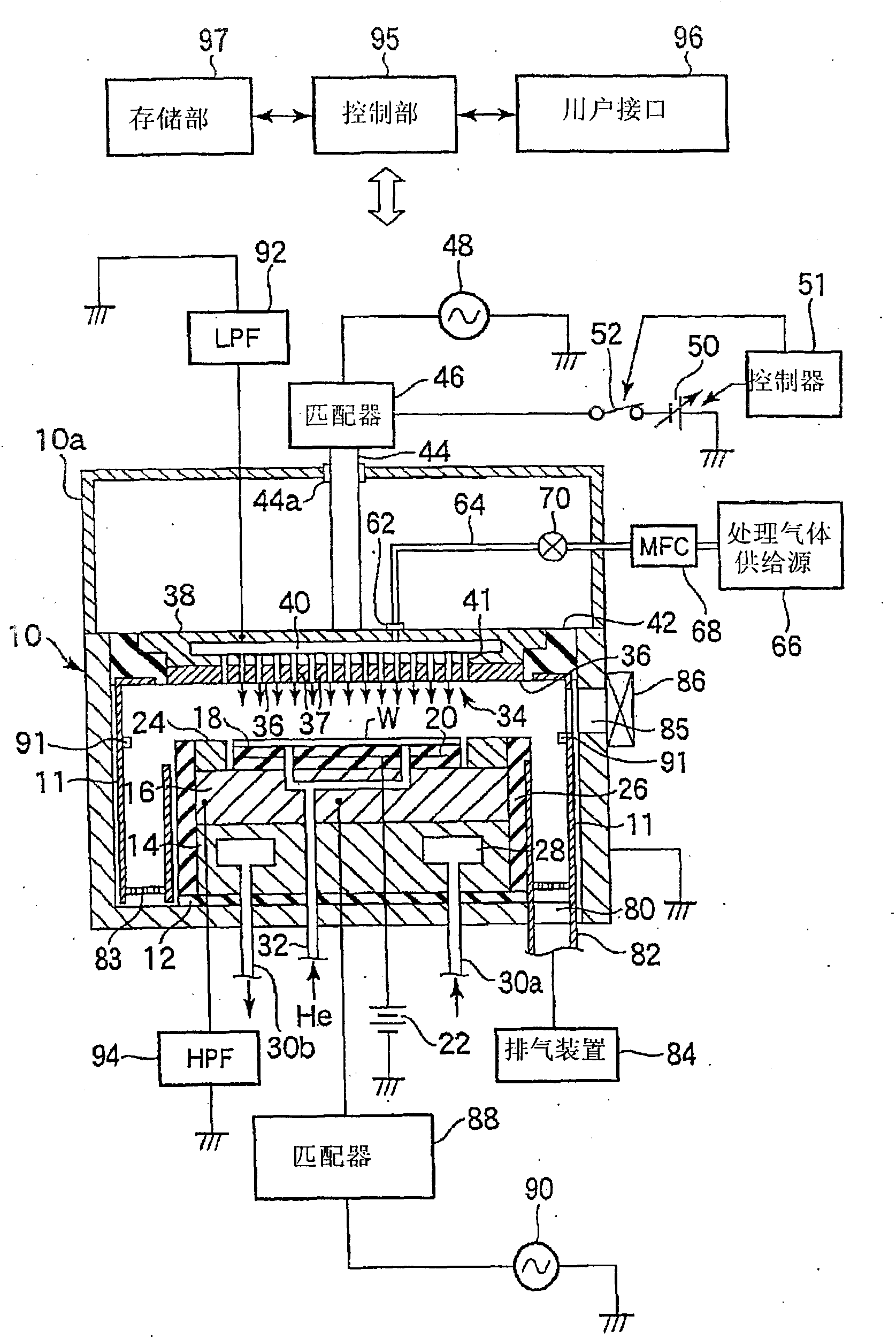

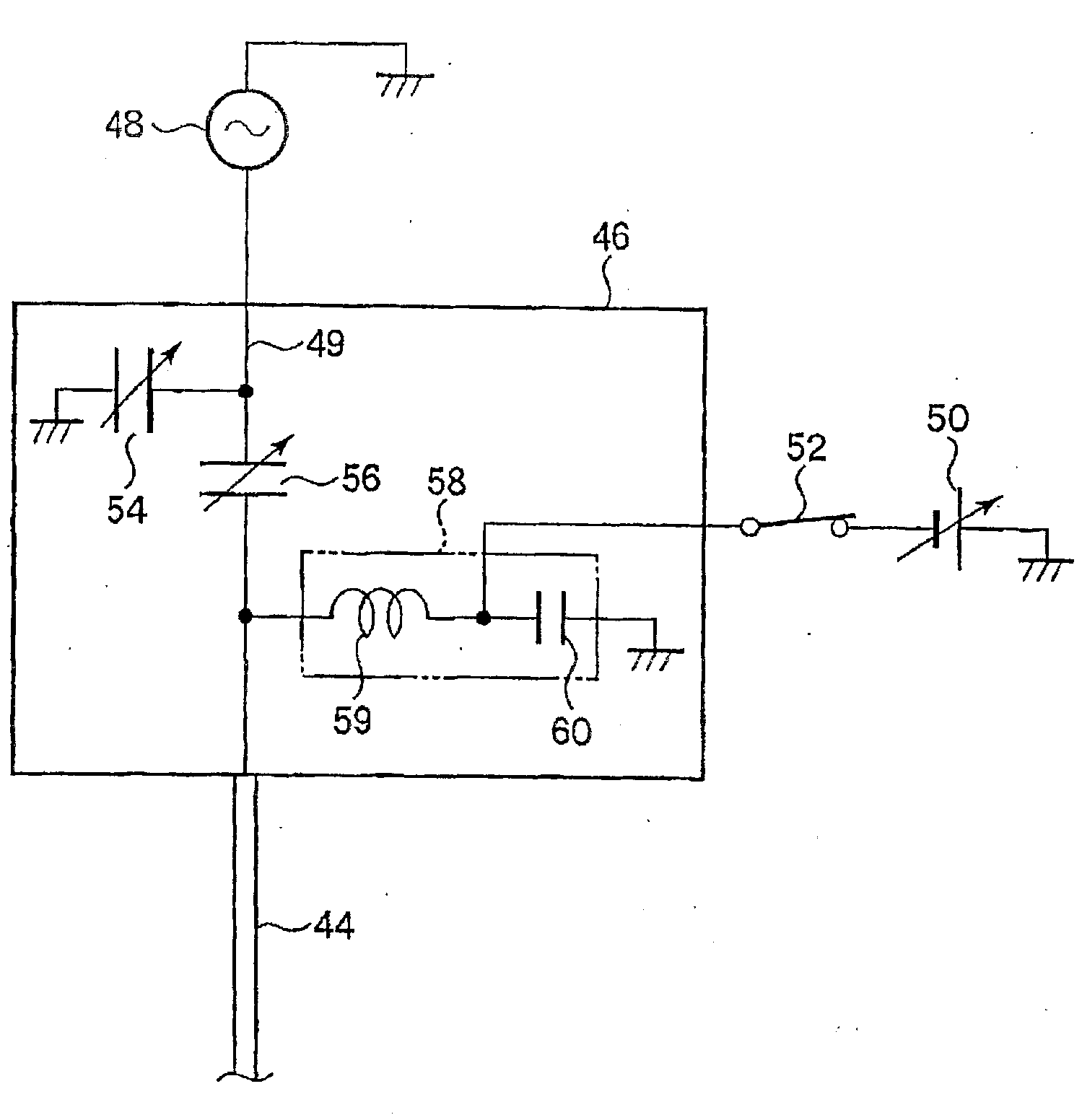

[0214] First, the first embodiment will be described. figure 1 It is a schematic cross-sectional view showing the plasma etching apparatus of the first embodiment of the present invention.

[0215] The plasma etching apparatus is configured as a capacitive coupling type parallel plate plasma etching apparatus, and has a substantially cylindrical chamber (processing container) 10 made of, for example, aluminum whose surface is anodized. The chamber 10 is safely grounded.

[0216] At the bottom of the chamber 10, a cylindrical susceptor support 14 is arranged via an insulating plate 12 made of ceramic or the like, and a susceptor 16 made of, for example, aluminum is provided on the susceptor support 14. The susceptor 16 constitutes a lower electrode, and a semiconductor wafer W as a substrate to be processed is mounted thereon.

[0217] On the upper surface of the susceptor 16, an electrostatic chuck 18 for holding the semiconductor wafer W by electrostatic force is provided. The el...

Embodiment approach 2

[0363] Next, the second embodiment of the present invention will be described.

[0364] Figure 34 It is a schematic cross-sectional view showing a plasma etching apparatus according to a second embodiment of the present invention. in Figure 34 In, and figure 1 The same components are denoted by the same symbols, and the description is omitted.

[0365] In this embodiment, an upper electrode 34' having the following structure is provided instead of the upper electrode 34 of the first embodiment. The upper electrode 34' is composed of a ring-shaped outer upper electrode 34a arranged opposite to the base 16 at a predetermined interval, and a disc-shaped inner upper electrode 34b arranged on the radially inner side of the outer upper electrode 34a in an insulated state constitute. They are related to the generation of plasma, and have a relationship in which the outer upper electrode 34a is the main and the inner upper electrode 34b is the auxiliary.

[0366] As in Figure 35 As sh...

no. 3 approach

[0409] In the third embodiment, components common to the first and second embodiments are denoted by the same symbols.

[0410] Figure 40 It is a schematic cross-sectional view showing the plasma etching apparatus of the third embodiment of the present invention.

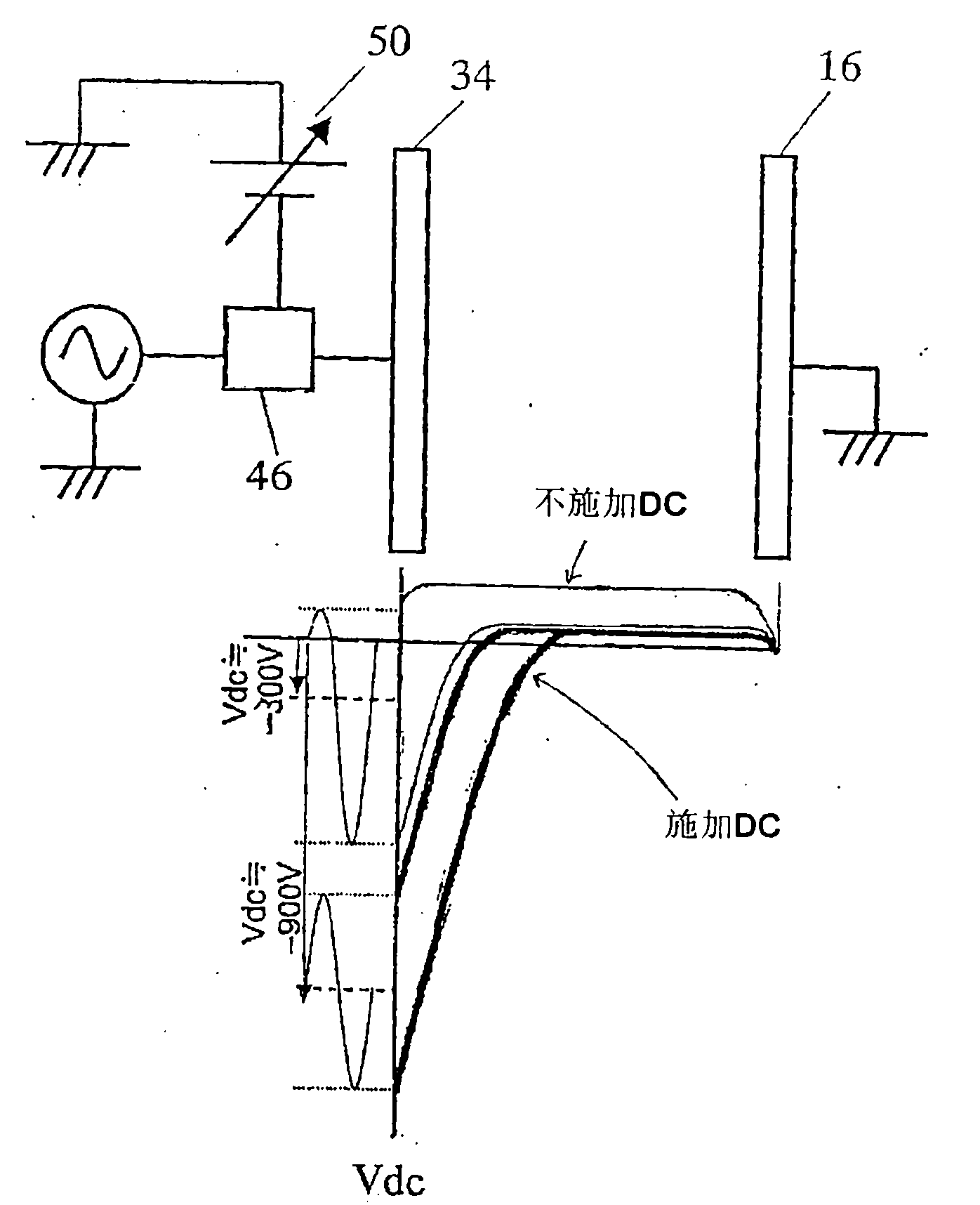

[0411] That is, it is applied from the first high-frequency power supply 88 to the susceptor 16 as the lower electrode, for example, 40 MHz high-frequency (RF) power for plasma generation, and from the second high-frequency power source 90 to the susceptor as the lower electrode 16 A lower RF dual-frequency application type plasma etching device that applies high-frequency (RF) power of, for example, 2 MHz for ion introduction, as shown in the figure, connects a variable DC power source 50 to an upper electrode 34 to apply it A plasma etching device with a specified direct current (DC) voltage. use Figure 41 The plasma etching apparatus will be described in detail.

[0412] This plasma etching apparatus is configured a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com