Gyratory crusher with arrangement for restricting rotation

一种回转破碎机、破碎机的技术,应用在谷物处理等方向,能够解决液压泵复杂、被污垢堵塞、易破裂等问题,达到简单设计、减少停机的次数、强大而简单反自转功能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

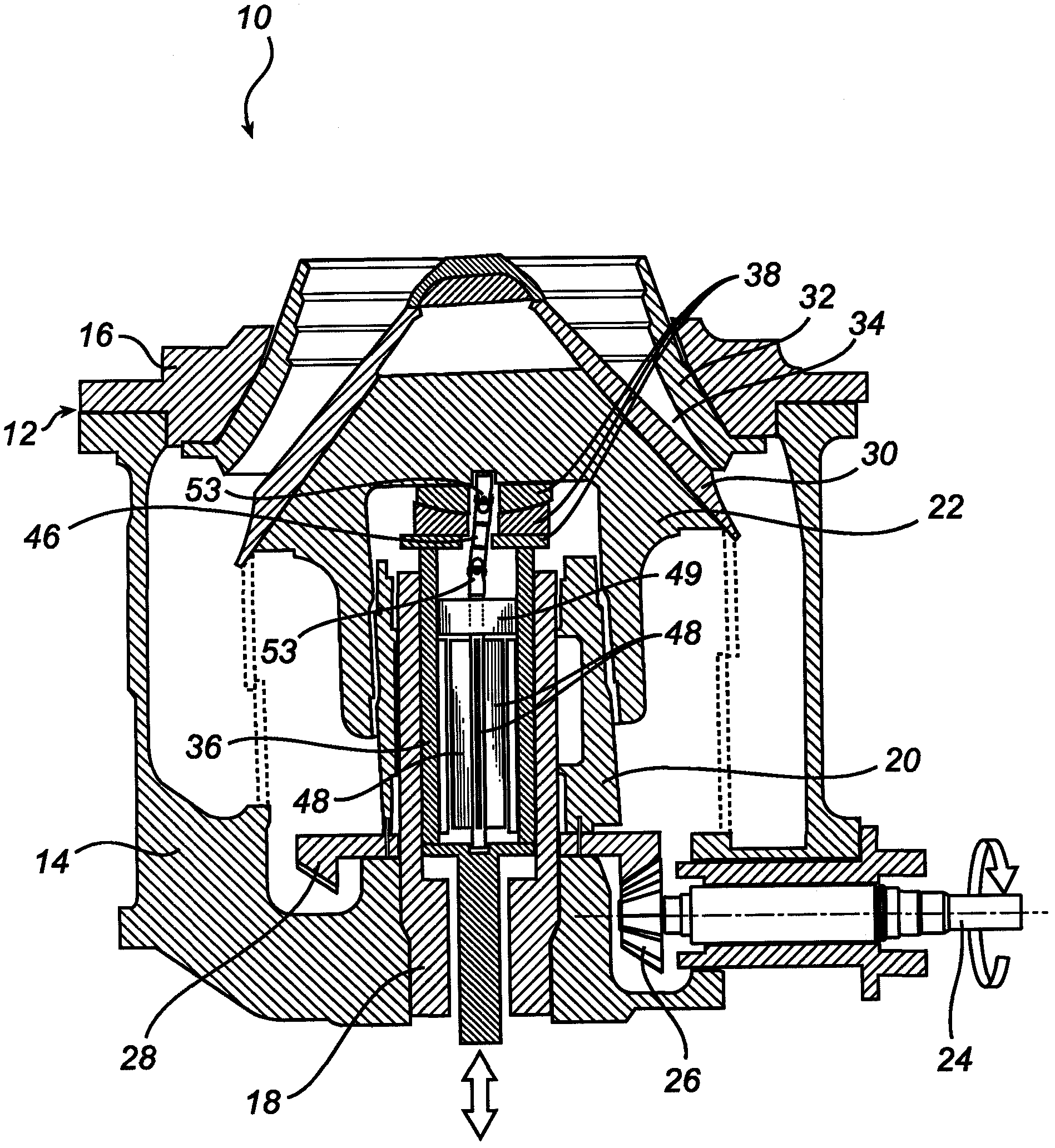

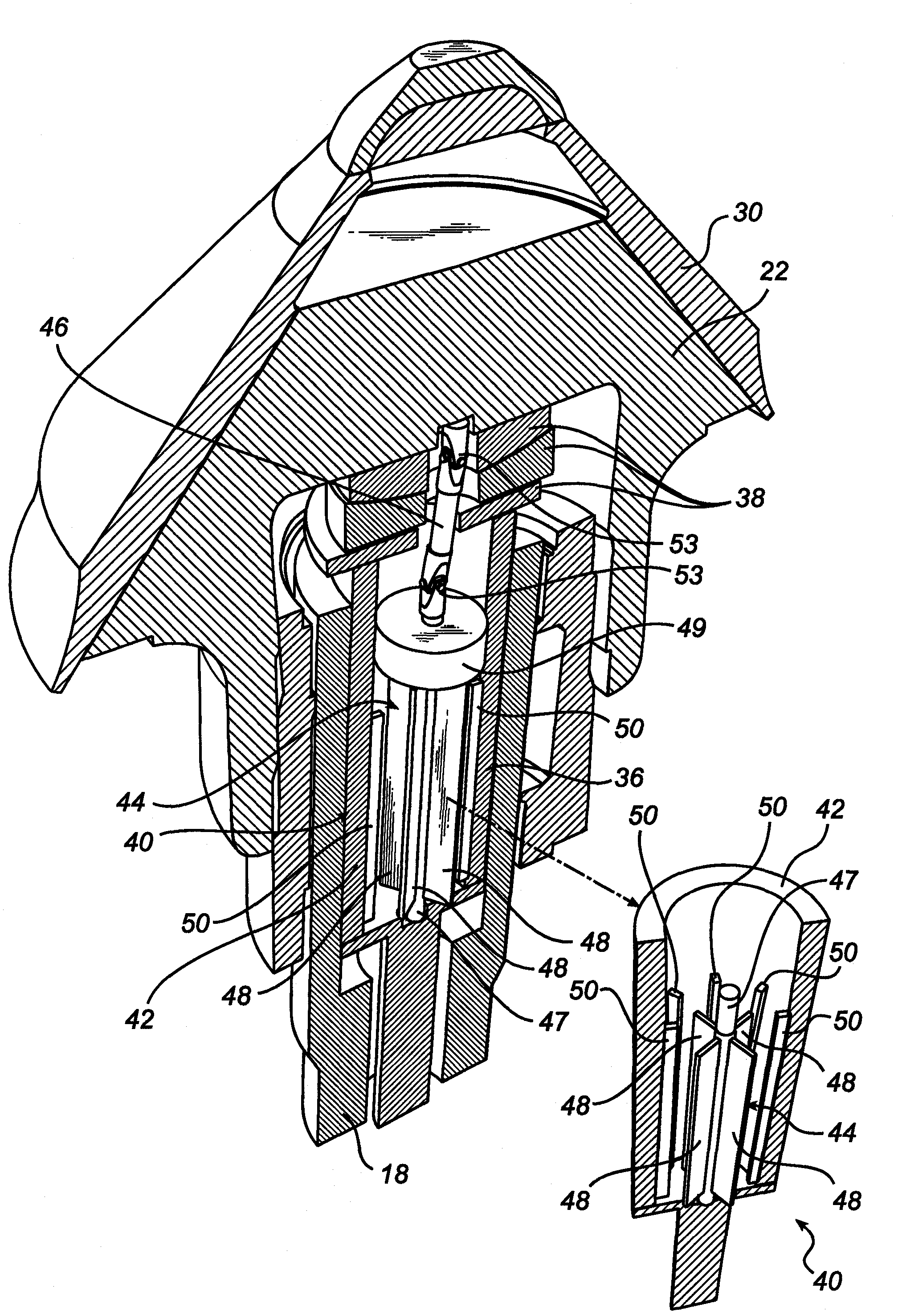

[0023] figure 1 A gyratory crusher 10 is schematically shown having a frame 12 including a frame bottom 14 and a frame top 16 . A vertical center shaft 18 is fixedly attached to the frame bottom 14 of the frame 12 . The eccentric 20 is arranged rotatably about the central axis 18 . The crushing head 22 is rotatably mounted about the eccentric 20 and thus about the central axis 18 . The drive shaft 24 is arranged such that the eccentric 20 is rotated about the central axis 18 by means of a bevel gear 26 meshing with a ring gear 28 connected to the eccentric 20 . Such as figure 1 As shown and known per se from the prior art, the outer circumference of the eccentric 20 is slightly inclined with respect to the vertical plane. Due to the inclination of the periphery of the eccentric 20, the crushing head 22 will also be slightly inclined with respect to the vertical plane. figure 1 The crusher 10 shown is of a version without top bearings.

[0024] The first crushing shell 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com