Continuous press slab entry angle automatic adjustment device

An entry angle, automatic adjustment technology, applied in the direction of presses, household components, flat products, etc., can solve the problems of reduced service life of dual output piston cylinders, complex manufacturing processes, and many rubber seals, etc., to extend service life, improve Lateral exhaust, the effect of reducing failure points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

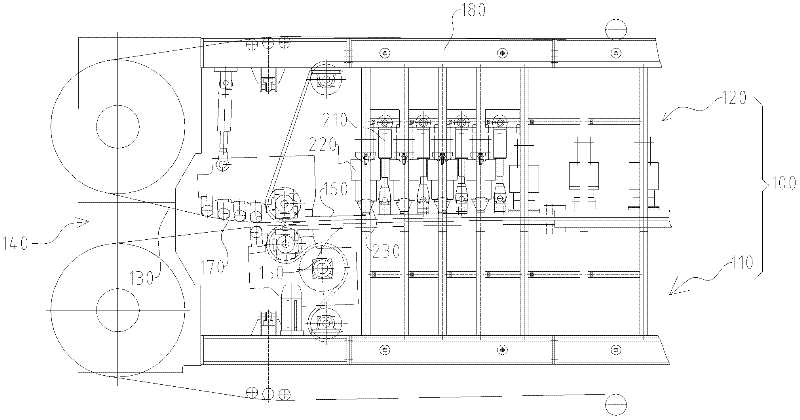

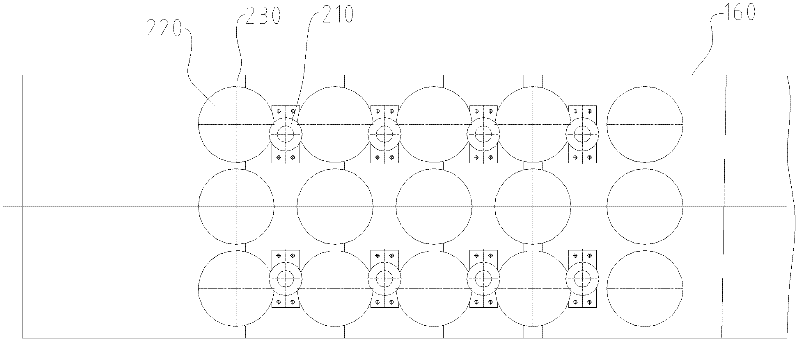

[0035] see Figure 1 to Figure 5 The continuous press 100 shown has a press lower part 110 and a press upper part 120, also has a compaction steel belt 130 running continuously in the press lower part 110 and the press upper part 120 and a feed port 140, in the A feeding heating plate 150, 160 is respectively arranged in the lower part 110 of the press machine and the upper part 120 of the pressing machine. A feeding profile 170 is formed between the feeding heating plate 160 on the top and the feeding heating plate 150 below. The heating plate 160 can adjust the pressing gap relative to the feeding heating plate 150 below, so that a continuous press 100 can press plates with different thicknesses, such as plates with a thickness of 2mm, 16mm, and 25mm.

[0036] The pressing steel strip 130 is supported on the feeding heating plates 150, 160 by rollers.

[0037] The feed profile 170 of the feed opening 140 is adjusted within the range of the feed heating plates 150 , 160 by m...

Embodiment 2

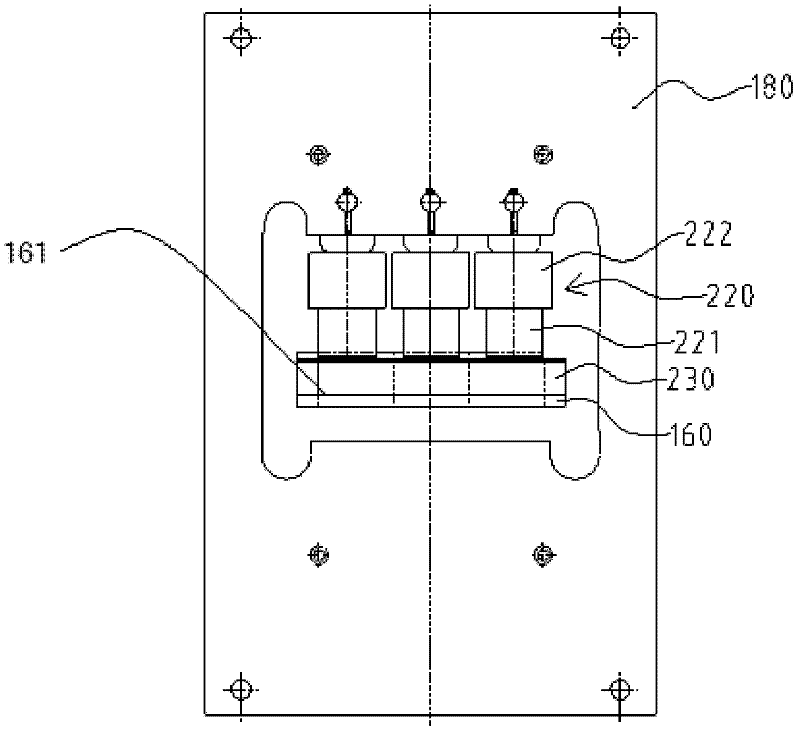

[0051] The difference between the present embodiment and the first embodiment is that the hinge structure between the cylinder body 222 of the plunger cylinder 220 and the upper hinge seat 182 is different, and the rest are the same as the first embodiment.

[0052] see Figure 13 to Figure 15 The top of the cylinder body 222 of the plunger cylinder 220 is symmetrically provided with two parallel inner pits 222e, 222f with the central axis of the cylinder body, and the pit bottoms of the two inner pits 222e, 222f are inner concave arc surfaces of the same diameter . Between the two inner pits 222e, 222f, a strip-shaped upper hinge seat pressing block positioning boss 222g is arranged, and two positioning holes 222h, 222i and two bolts are separated on the upper hinge seat pressing block positioning boss 222g. The inner diameters of the holes 222j, 222k, the positioning holes 222h, 222i are larger than the inner diameters of the bolt holes 222j, 222k.

[0053] A groove 182d i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com