Special coating for wind turbine blades and its construction technology

A technology for wind turbines and construction techniques, applied in wind turbine components, wind engines, wind power generation, etc., to achieve the effects of reduced processing workload, good impact resistance, and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The wind power generator blade special coating of the present embodiment comprises: solid content in 80%~70% hydroxyacrylic resin 40kg, titanium dioxide R25kg, quartz powder 1250 order 30kg, clay 0.5kg, wax paste 0.5kg, wax powder 9322F 2kg, 0.5kg of 4050 dispersant, 4500.3kg of leveling agent, 1kg of defoamer 6800, 0.5kg of 10% organotin, 13kg of butyl ester and a small amount of color masterbatch. After the above-mentioned ingredients are prepared, mix them with HDI at the ratio of amino value 6-9:1.

[0026] Construction process:

[0027] (1) After mixing the special paint for wind turbine blades and curing agent HDI according to the amino value calculation ratio of 6-9:1, paint on the two half-moulds of the blade mould, and it needs to be painted twice to form Gel coat layer, the thickness of the gel coat layer is 500μm, if there are other specific needs, it can be painted three times to make the thickness of the gel coat layer more than 500μm;

[0028] (2) The ge...

Embodiment 2~ Embodiment 4

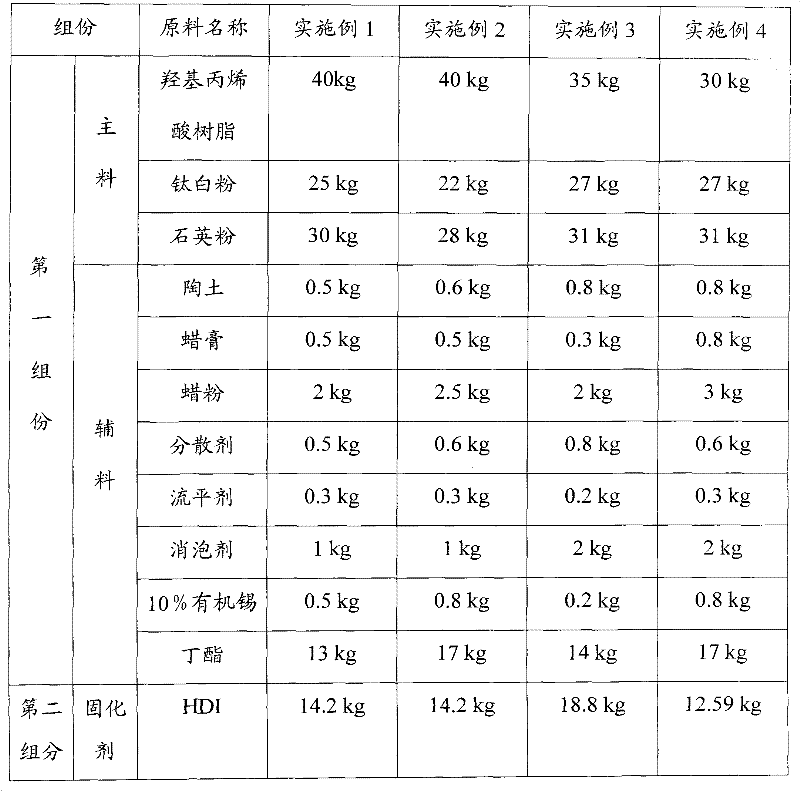

[0033] The components of the wind power generator blade special coating of each embodiment are shown in Table 1, and the construction technology of each embodiment is basically the same as that of Example 1, the difference being that the different proportioning of each component of each embodiment makes the gel coat The tack-free time and the heat-curing time of the leaves were changed.

[0034] Table 1

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap