Anionic water-based waterproof paint and preparation method thereof

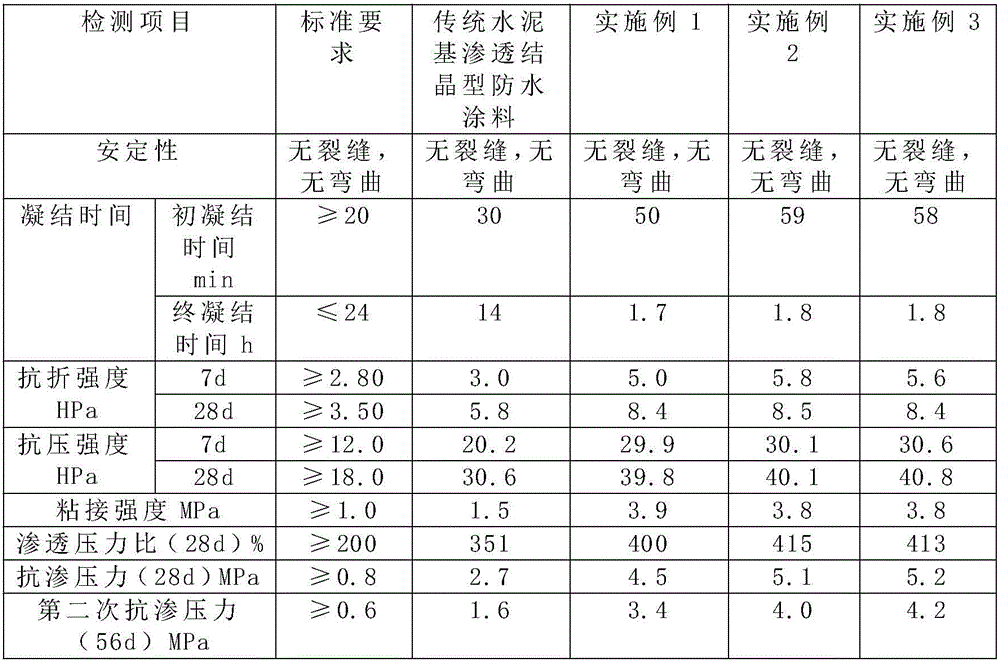

A waterproof coating and anion technology, applied in the field of building waterproof coatings, can solve the problems of easy generation of dust, low impermeability pressure, timely maintenance, etc., and achieve the effects of improving bonding strength, increasing impermeability pressure, and improving wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] An anionic water-proof coating, comprising the following components by weight: 20 parts of sodium silicate; 20 parts of sodium tetrapolyphosphate; 1.5 parts of hydroxypropyl methylcellulose with a molecular weight of 40,000 to 60,000; 0.5 parts of penetrant T ; 1 part of penetrant BX; 1 part of penetrant JFC; 1 part of isooctyl diethylhexanol; 80 parts of water.

[0029] The above-mentioned anionic water-proof paint is prepared by the following method:

[0030] Accurately weigh each component according to the formula requirements, first add water into the mixing tank, turn on the mixer, rotate at 400 rpm, slowly add sodium silicate, sodium tetrapolyphosphate and additives, stir for 30 minutes to dissolve completely , and then stop the machine to discharge and filter the package to obtain the anion water waterproof coating.

Embodiment 2

[0032] An anionic water-proof coating, comprising the following components by weight: 10 parts of modified sodium silicate; 15 parts of sodium tetrapolyphosphate; 1.5 parts of hydroxypropyl methylcellulose; 1 part of penetrant T; 1 part of penetrant BX 1.5 parts of isooctyl alcohol diethylhexanol; 60 parts of water; the modified sodium silicate is composed of the following parts by weight: 20 parts of sodium silicate; 10 parts of magnesium sulfate; 5 parts of aluminum sulfate; 1 part of sodium sulfonate; 1 part of sodium hydroxide; 80 parts of water obtained by reaction.

[0033] The above-mentioned anionic water-proof paint is prepared by the following method:

[0034] (1) Accurately weigh each component according to the recipe requirements, first add sodium silicate into the mixing tank, add water, turn on the mixer, rotate at 300 rpm, stir for 20 minutes to obtain an aqueous solution of sodium silicate, and then slowly add hydrogen Sodium oxide, after stirring for 20 minut...

Embodiment 3

[0037] Prepare described anionic water-proof coating according to the following method:

[0038] (1) Take the following components by weight according to the formula: 30 parts of sodium silicate, 5 parts of magnesium sulfate, 10 parts of aluminum sulfate, 5 parts of sodium lignosulfonate, 3 parts of sodium hydroxide, and 60 parts of water. Add sodium silicate into the mixing tank, add water, turn on the mixer at a speed of 300 rpm, stir for 20 minutes to obtain an aqueous solution of sodium silicate, then slowly add sodium hydroxide, and stir for 20 minutes at a speed of 300 rpm. Slowly add magnesium sulfate, aluminum sulfate, and sodium lignosulfonate, and stir for 40 minutes under the conditions of 50°C and 400 rpm to obtain the modified sodium silicate, which is set aside.

[0039] (2) Take the following components in parts by weight according to the formula requirements: 15 parts of modified sodium silicate, 15 parts of sodium tetrapolyphosphate, 2 parts of hydroxypropyl m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap