A high-performance corrosion-resistant dry-mixed waterproof mortar

A waterproof mortar and corrosion-resistant technology, applied in the field of mortar, can solve problems such as inconvenience of use and self-coagulation, and achieve the effect of increasing the density, reducing the water-binder ratio, and reducing the amount of cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A high-performance corrosion-resistant dry-mixed waterproof mortar is prepared from the following raw materials in parts by weight:

[0040] 60 parts of cement, 35 parts of mineral powder, 10 parts of fly ash, 300 parts of recycled fine aggregate, 5 parts of compound admixture;

[0041] The compound admixture is prepared from the following raw materials in parts by weight: 40 parts of fly ash, 5 parts of water repellent, 40 parts of expansion agent, 2 parts of air-entraining water reducer, 2 parts of anti-crack short fiber, water retention Thickener 2 parts.

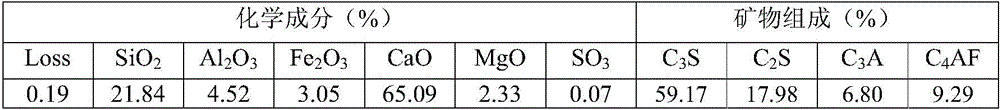

[0042] Among the above raw materials, the C3A content of the cement is less than 7%, and the composition is as follows:

[0043]

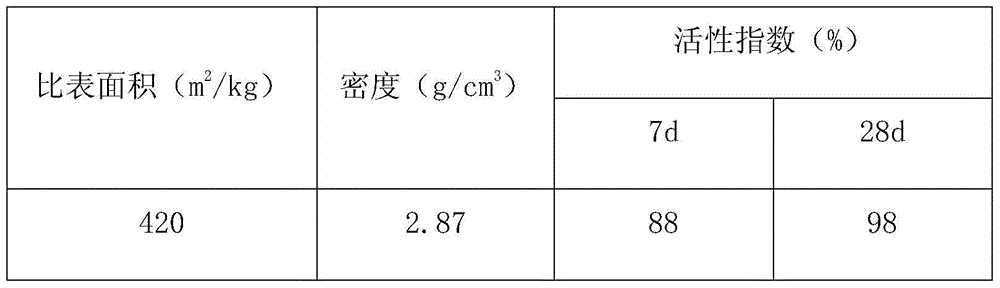

[0044] The fly ash is Class I fly ash, the 45 micron sieve is not more than 12%, and the loss on ignition is not more than 5%. The ore powder is S95 grade steel slag fine powder, and the 45 micron sieve is not more than 1%. Recycled fine aggregate refers to the fine aggregate obt...

Embodiment 2

[0046] A high-performance corrosion-resistant dry-mixed waterproof mortar is prepared from the following raw materials:

[0047] 70 parts of cement, 45 parts of mineral powder, 30 parts of fly ash, 500 parts of recycled fine aggregate, and 10 parts of compound admixture;

[0048] The compound admixture is prepared from the following raw materials in parts by weight: 60 parts of fly ash, 7 parts of water-repellent agent, 50 parts of expansion agent, 5 parts of air-entraining water reducer, 4 parts of anti-crack short fiber, water-retaining 10 parts of thickener.

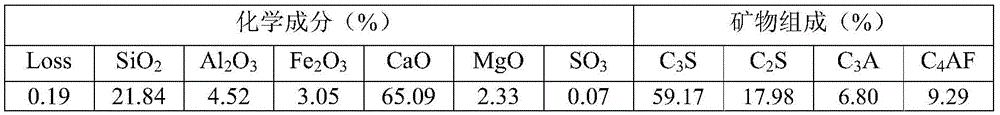

[0049] Among the above raw materials, the fly ash is Class I fly ash. The ore powder is S95 steel slag powder. Recycled fine aggregate refers to the fine aggregate obtained after waste concrete is separated, crushed, shaped, and screened. The water-repellent agent adopts silicone-based water-repellent agent. The expansion agent adopts UEA expansion agent. The air-entraining superplasticizer adopts high-performanc...

Embodiment 3

[0051] A high-performance corrosion-resistant dry-mixed waterproof mortar is prepared from the following raw materials in parts by weight:

[0052] 65 parts of cement, 40 parts of mineral powder, 20 parts of fly ash, 400 parts of recycled fine aggregate, 8 parts of compound admixture;

[0053]The compound admixture is prepared from the following raw materials in parts by weight: 50 parts of fly ash, 6 parts of water-repellent agent, 45 parts of expansion agent, 4 parts of air-entraining water-reducing agent, 3 parts of crack-resistant short fiber, water-retaining Thickener 6 parts.

[0054] Among the above raw materials, the fly ash is Class I fly ash, the 45 micron sieve residue is not more than 12%, and the loss on ignition is not more than 5%. The ore powder is S95 grade steel slag fine powder, and the sieve residue of 45 microns is not more than 1%. The regenerated fine aggregate refers to the fine aggregate obtained after separation, crushing, shaping and screening of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com