A labyrinth wind blocking device for printing and dyeing industry

A labyrinth-type, wind-blocking technology, applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve the problems of loss of leak-proof effect, guide roller stuck, poor leak-proof effect, etc., to improve decompression blocking, High operating sensitivity and small thermal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

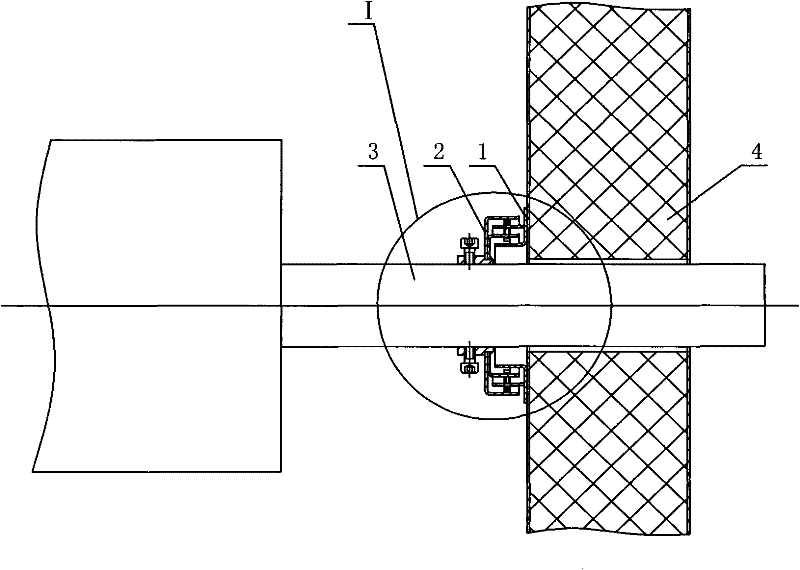

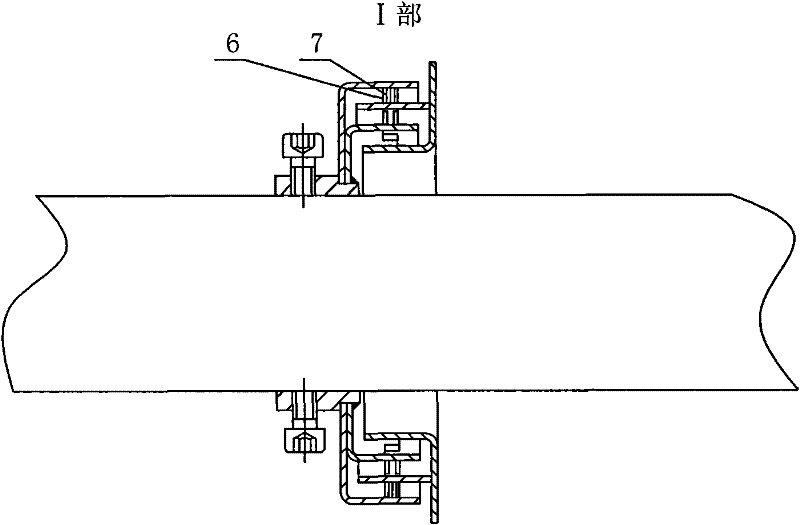

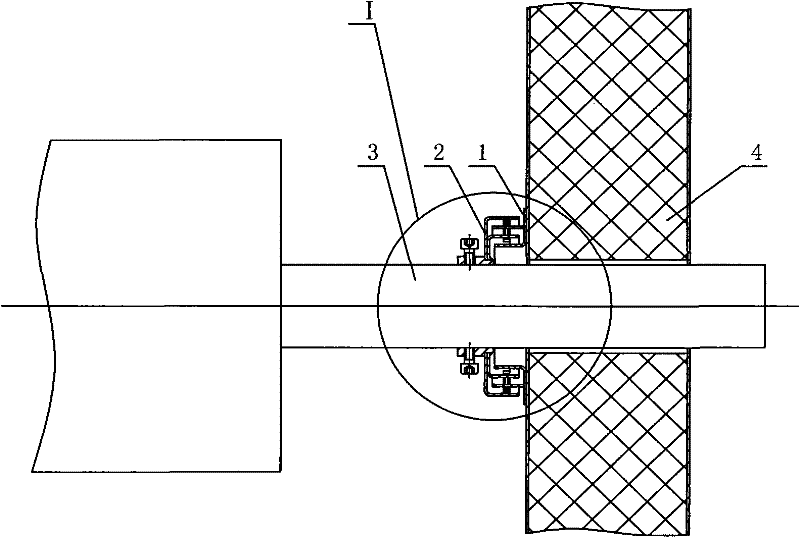

[0017] The labyrinth wind blocking device of the present invention comprises a fixed wind blocking ring 1 connected with the thermal insulation door panel and a rotating wind blocking ring 2 connected with the shaft head of the guide roller.

[0018] The fixed wind blocking ring 1 of the present invention is composed of a fixed inner ring and a fixed outer ring, and is connected and fixed to the inner side of the heat preservation door panel by bolts; a certain distance is formed between the fixed inner ring and the fixed outer ring.

[0019] The rotating wind choke ring 2 of the present invention is composed of a rotating inner ring, a rotating outer ring and a connecting sleeve. The shaft heads of the guide rollers rotate together; a certain distance is formed between the rotating inner ring and the rotating outer ring.

[0020] The center of the rotating wind-blocking ring 2 takes the center of the guide roller as the center of rotation, and the panel connecting the fixed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com