Backlight module, surface light source module and light guide grid structure

A technology of backlight module and grid structure, which is applied in the field of surface light source modules that can emit light uniformly, and can solve the problems of long light guide distance consumption, difficult diffusion and homogenization of light-emitting diode point light sources, and inability to easily achieve flexibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

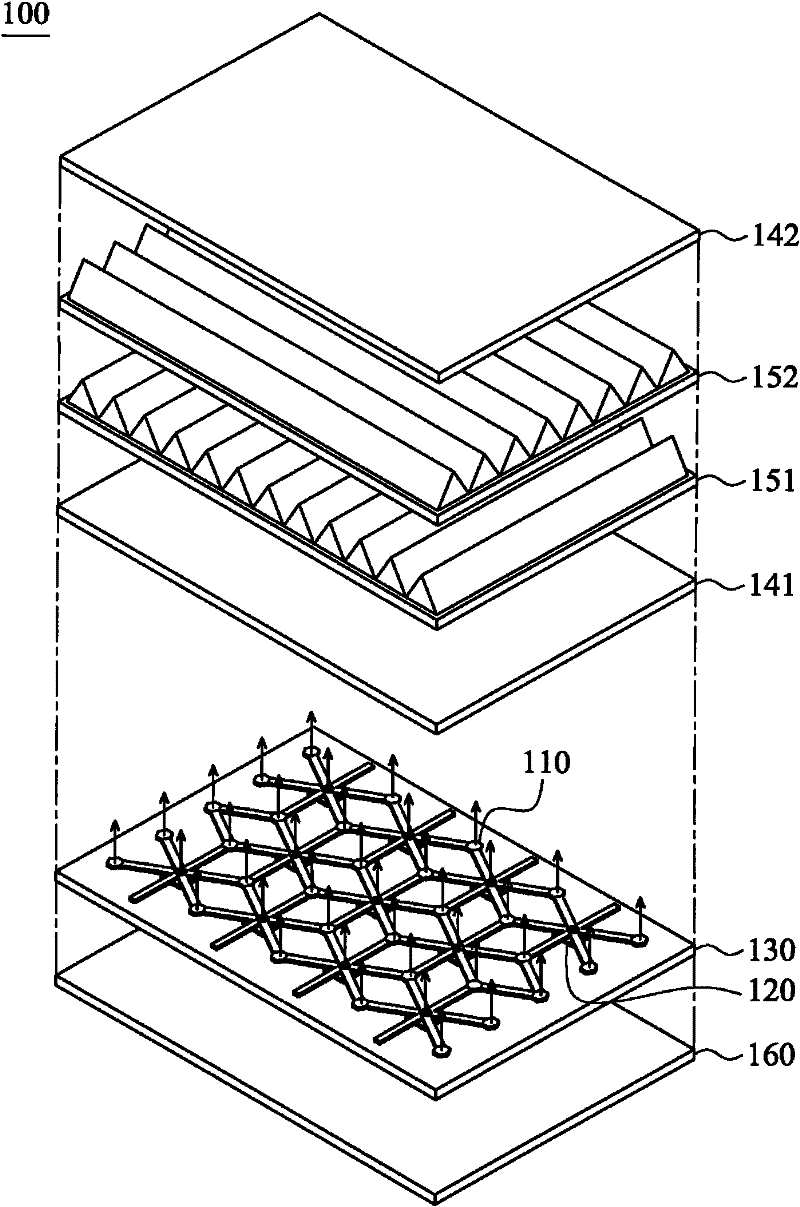

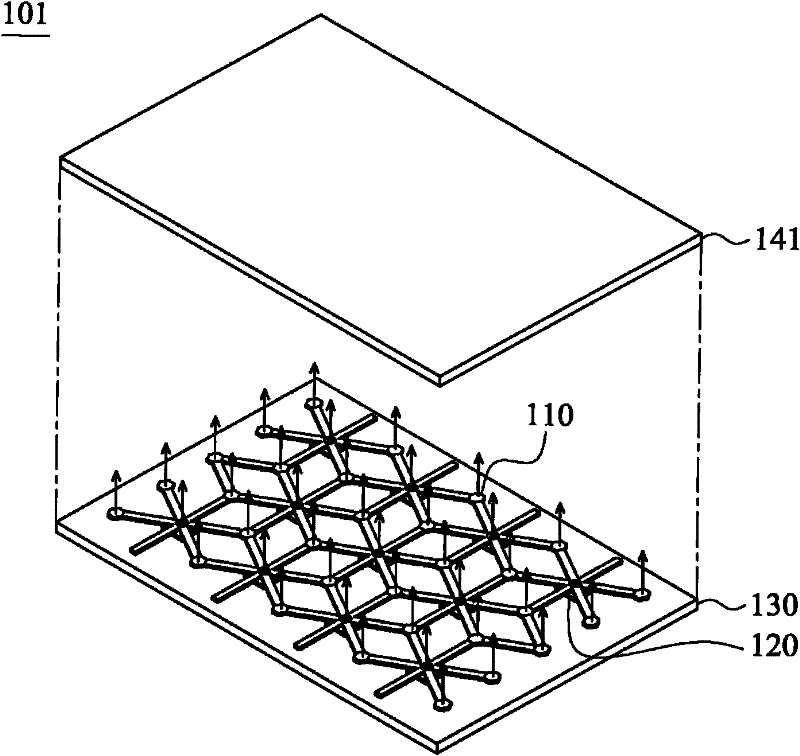

[0068] refer to Figure 1A , which is a backlight module 100 showing an embodiment of the present invention, including a light guide grid structure 110, a light source (light emitting diode) 120, a substrate 130, a diffusion film 141, a diffusion film 142, a prism sheet 151, a prism sheet 152, and a heat dissipation backplane 160. The light source 120 is disposed on the substrate 130 . Wherein, the prism sheet 151 may be a vertical row prism sheet, and the prism sheet 152 may be a horizontal row prism sheet. refer to Figure 1B , which is a characteristic part of the surface light source module (surface light source module 101 ) showing an embodiment of the present invention, including a light guide grid structure 110 , a light source (light emitting diode) 120 , a substrate 130 and a diffusion film 141 .

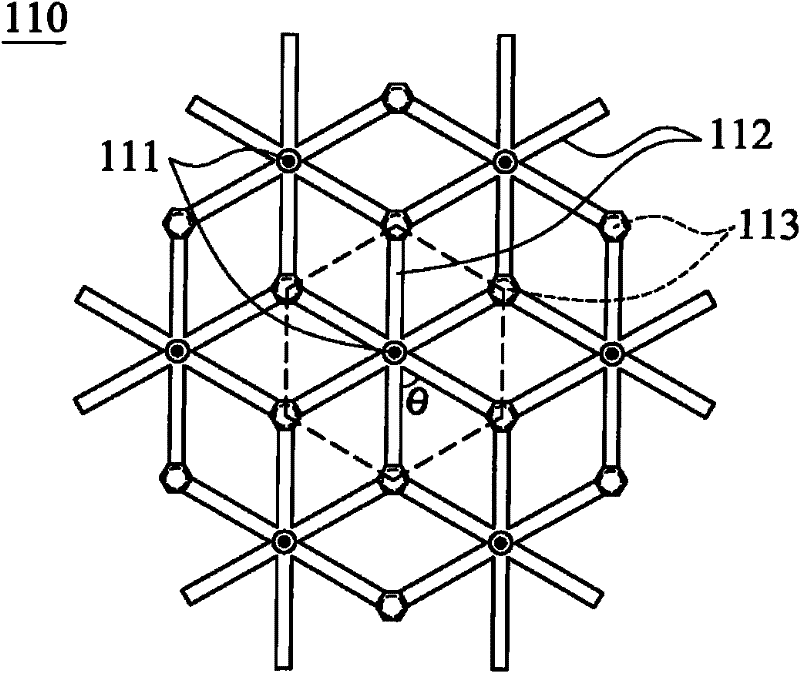

[0069] Figure 2A It is an embodiment showing the grid distribution of the light guide grid structure, Figure 2B It is a cross-sectional view showing the detailed stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com