Explosion-proof device for boiler

An explosion-proof device and boiler technology, which is applied in the direction of lighting and heating equipment, fluid heaters, etc., can solve the problems of personal casualties, boilers with simple structure, and damage to the main body of the boiler, and achieve the effect of good explosion-proof effect, simple structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

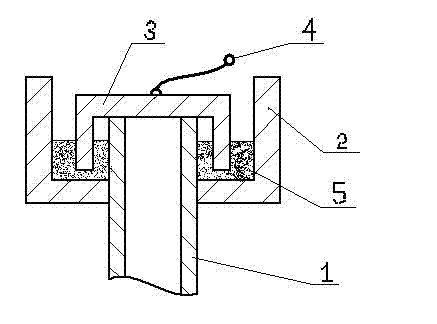

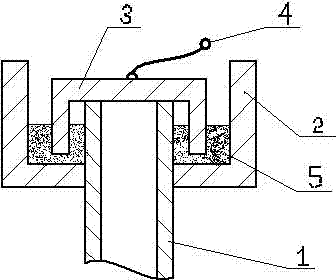

[0011] Below in conjunction with drawing, the present invention is described in detail:

[0012] As shown in the accompanying drawings, in the figure: 1, the middle hollow shaft, 2, the groove, 3, the cover plate, 4, the hinge, 5, the sealing water layer. It includes an intermediate hollow shaft that can go deep into the airflow channel inside the boiler body, a groove that surrounds the upper end of the intermediate hollow shaft, and its connection with the intermediate hollow shaft is a seamless and fixed connection, and covers the upper end surface of the intermediate hollow shaft. Cover with raised edges. A rock wool sealing ring to prevent gas leakage is provided at the contact between the cover plate and the upper end surface of the intermediate hollow shaft. A hinge connected with the boiler body is arranged on the cover plate to prevent the cover plate from flying away and hurting people when an explosion occurs.

[0013] The above-mentioned embodiments are only one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com