A special interface for sf6 inflatable equipment live test micro water

A technology for inflatable equipment and electrified testing, which is applied to measuring devices, liquid tightness measurement using liquid/vacuum degree, instruments, etc. It can solve problems such as short maintenance period, lack of pre-test, equipment beyond the test period, etc., to achieve High safety performance, wide application range and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

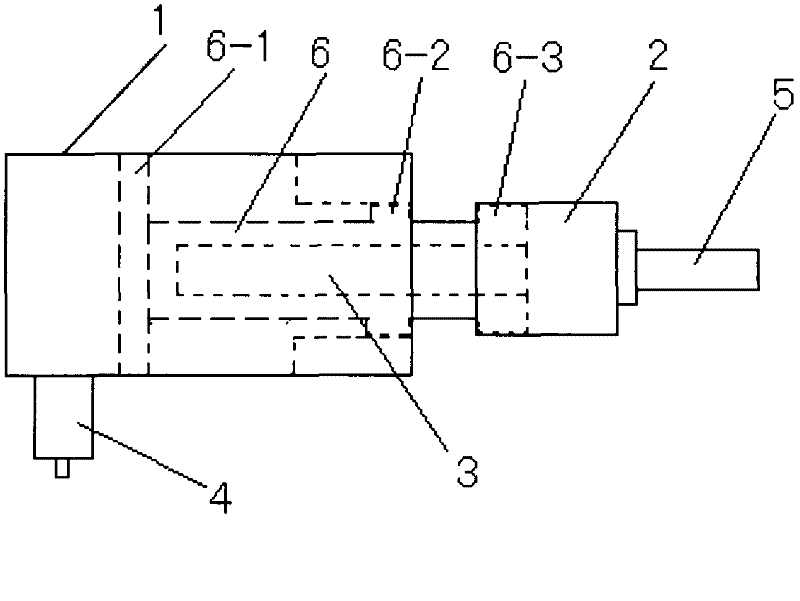

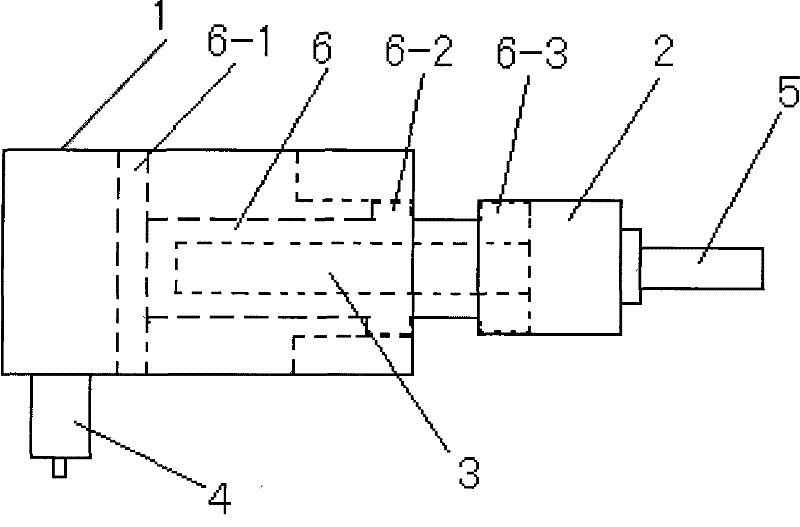

[0009] The specific embodiment: below in conjunction with accompanying drawing, the best embodiment of the present invention is described in detail:

Embodiment

[0010] Embodiment: a special interface for SF6 inflatable equipment live test micro-water (see the accompanying drawings), which includes a sealing nut 1, the front end of the sealing nut 1 is provided with a gas release valve 4, and the thimble connecting rod is movably connected in the sealing nut 1 6. The rear end of the thimble connecting rod 6 is movably connected to the quick interface filter device 2, the front and rear bosses of the sealing nut 1 are provided with threads, and the front part of the quick interface filter device 2 is provided with threads, and the thimble connecting rod The front end boss 6-1, the middle boss 6-2 and the rear boss 6-3 of 6 are provided with threads, and the front and rear parts of the sealing nut 1 pass through the front boss 6-1 and the middle boss respectively. 6-2 is threadedly connected with the thimble connecting rod 6, and the thimble connecting rod 6 can move back and forth in the sealing nut 1. The thimble connecting rod 6 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com