Lithium ion secondary battery anode material and preparation method

A secondary battery and negative electrode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of high cost, non-compliance, cumbersome preparation methods, etc., and achieve the effects of low cost, environmental protection, and high capacity retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The "lithium-ion secondary battery negative electrode material and preparation method thereof" provided by the present invention is to use the unburned carbon of a fuel oil (or coal-fired) fly ash as the carbon material, and the preparation method of the unburned carbon carbon material comprises the following steps: First, impregnate the fuel (or coal) fly ash, stir at room temperature at 200rpm for 2 hours, filter and separate the solid and liquid, then wash with distilled water several times to remove the residual impregnating agent, and dry at 105°C for 24 hours , that is, to obtain the unburned carbon material, so as to solve the existing multi-type carbon materials (such as: natural graphite, coal, carbon fiber and metastable spherical carbon (MCMB), and even non-graphitized carbon materials derived from resins. ) have problems such as low capacitance, environmental pollution and high price.

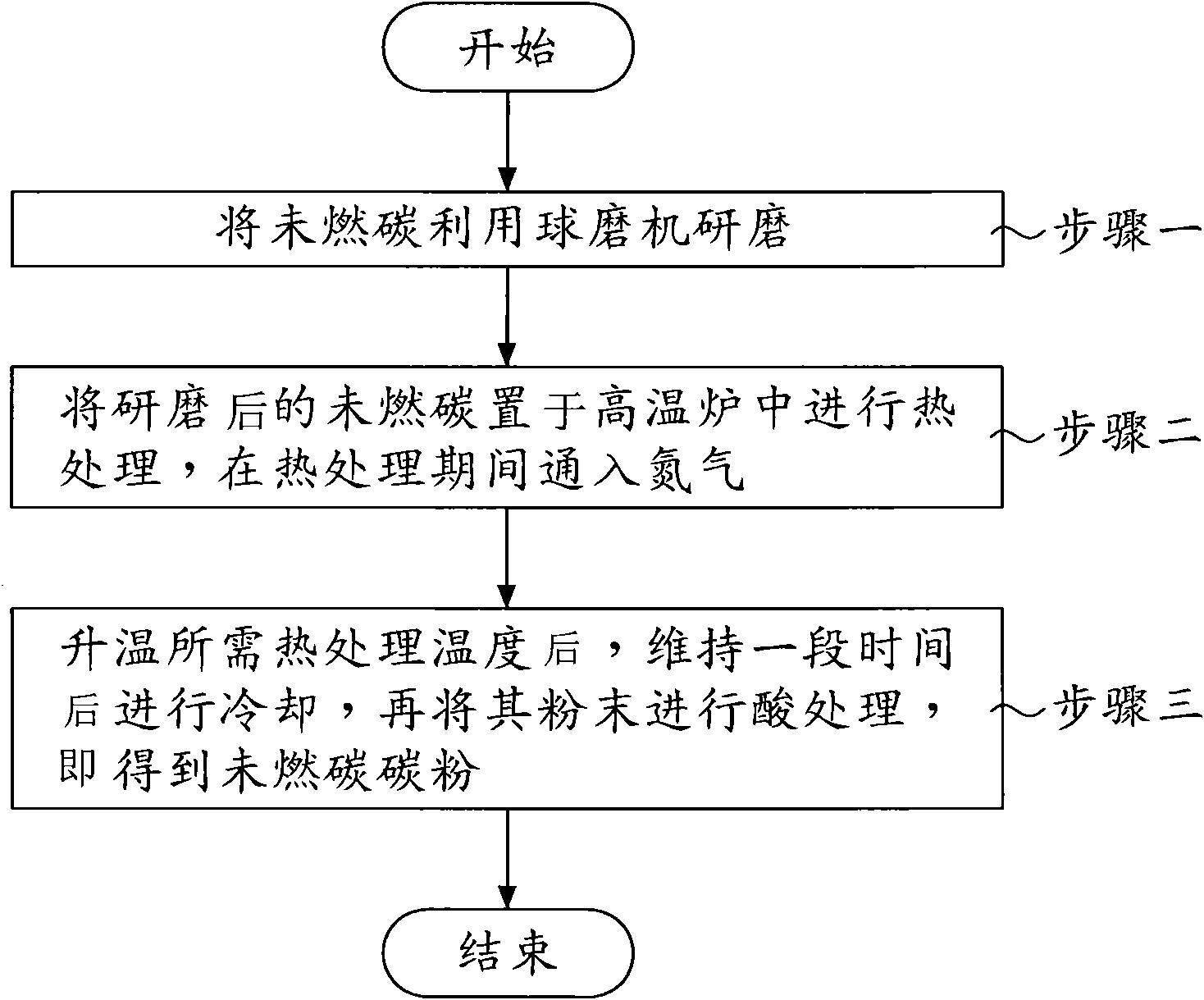

[0029] figure 1 For the preparation method of unburned carbon powder of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com