Graphene composite material loaded with cobalt niobate oxide and its preparation method and application

A technology of composite materials and cobalt oxides, applied in the direction of negative electrodes, active material electrodes, electrochemical generators, etc., can solve the problems of low theoretical capacity and poor conductivity of niobium-based oxides, and achieve improved electrochemical performance and large capacity , the effect of high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

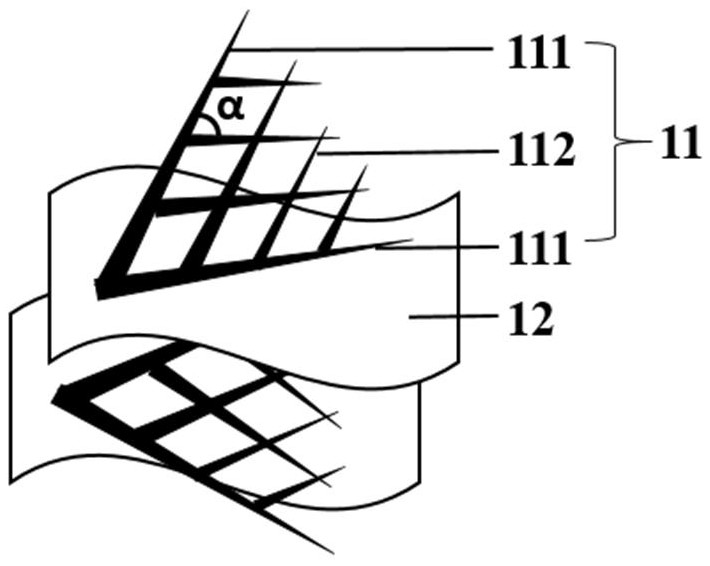

[0036] The present invention also provides a method for preparing the above-mentioned graphene composite material loaded with cobalt niobate oxide, comprising the following steps:

[0037] S1, providing a graphene oxide dispersion, and mixing the graphene oxide dispersion with a mixed solution to obtain a mixture, wherein the mixed solution includes a cobalt source and a niobium source;

[0038] S2, the mixture is sequentially subjected to ball milling and hydrothermal reaction, and then annealed to obtain the cobalt niobate-supported graphene composite material.

[0039] In step S1, the graphene oxide dispersion liquid includes graphene oxide and a dispersing solvent, wherein the graphene oxide can be prepared by the Hummers method, and the dispersing solvent is preferably anhydrous ethanol. In order to make the distribution of the graphene oxide dispersion more uniform, the graphene oxide dispersion can be ultrasonically dispersed and stirred for a certain period of time, sp...

Embodiment 1

[0056] 34 mg of graphene oxide and 40 mL of anhydrous ethanol were stirred in a 100 mL beaker for 10 min, and then ultrasonically dispersed for 30 min to obtain a graphene oxide dispersion.

[0057] 0.25 g of cobalt acetate tetrahydrate, 1.10 g of hydrated niobium oxalate and 60 mL of absolute ethanol were stirred in a 250 mL three-necked flask until completely dissolved to obtain a mixed solution.

[0058] Under the condition of a 60°C water bath, the graphene oxide dispersion was added dropwise to the three-necked flask containing the mixed solution, and stirred during the dropwise addition, and then continued to stir for 30 min after the dropwise addition to obtain a mixture.

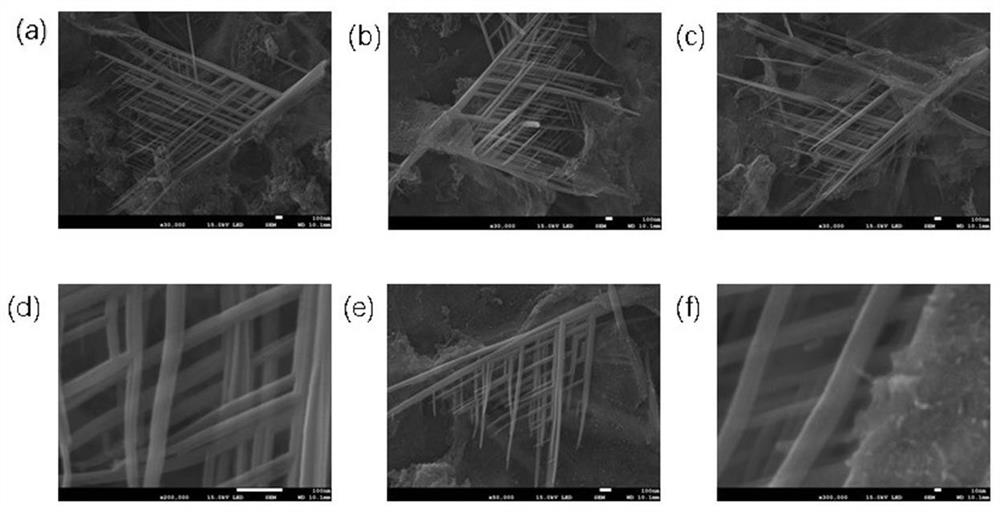

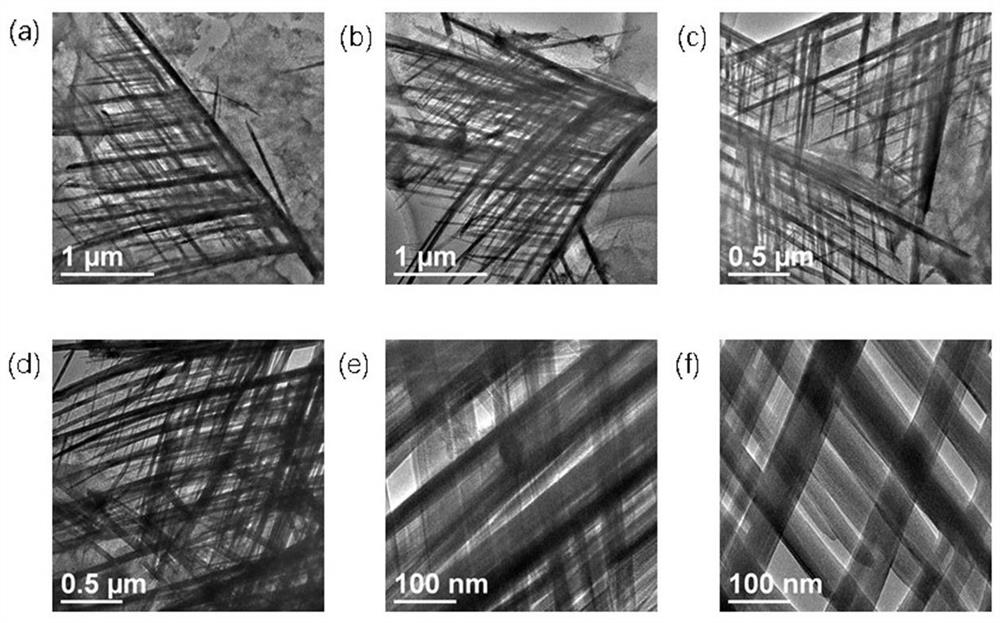

[0059] The mixture was transferred to a ball milling tank for ball milling at a speed of 600 rpm. After ball milling for 10.5 h, the reaction solution was transferred to a hydrothermal kettle, and the hydrothermal reaction was carried out at a temperature of 180 °C, and the reaction was kept at a cons...

Embodiment 2

[0063] 34 mg of graphene oxide and 40 mL of anhydrous ethanol were stirred in a 100 mL beaker for 10 min, and then ultrasonically dispersed for 30 min to obtain a graphene oxide dispersion.

[0064] 0.25 g of cobalt acetate tetrahydrate, 1.10 g of hydrated niobium oxalate and 60 mL of absolute ethanol were stirred in a 250 mL three-necked flask until completely dissolved to obtain a mixed solution.

[0065] Under the condition of a 60°C water bath, the graphene oxide dispersion was added dropwise to the three-necked flask containing the mixed solution, and stirred during the dropwise addition, and then continued to stir for 30 min after the dropwise addition to obtain a mixture.

[0066] The mixture was transferred to a ball milling tank for ball milling at a speed of 600 rpm. After ball milling for 10.5 h, the reaction solution was transferred to a hydrothermal kettle, and the hydrothermal reaction was carried out at a temperature of 180 °C, and the reaction was kept at a cons...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com