Automatic plate-wrapping method for lead-acid storage battery production

A lead-acid battery, automatic technology, applied in the direction of lead-acid battery, lead-acid battery construction, final product manufacturing, etc., can solve problems such as high labor intensity, serious lead pollution, and unfavorable health of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

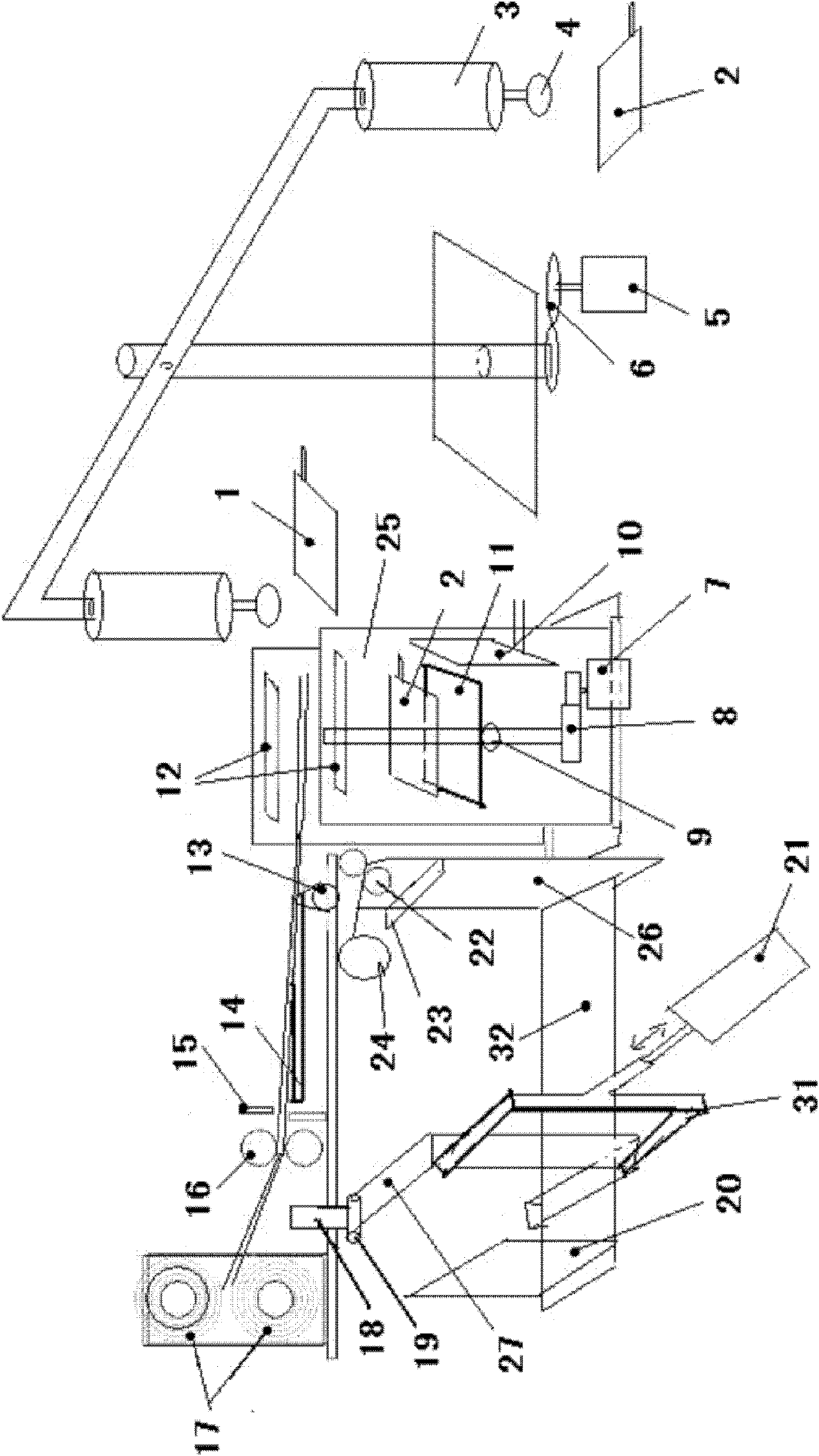

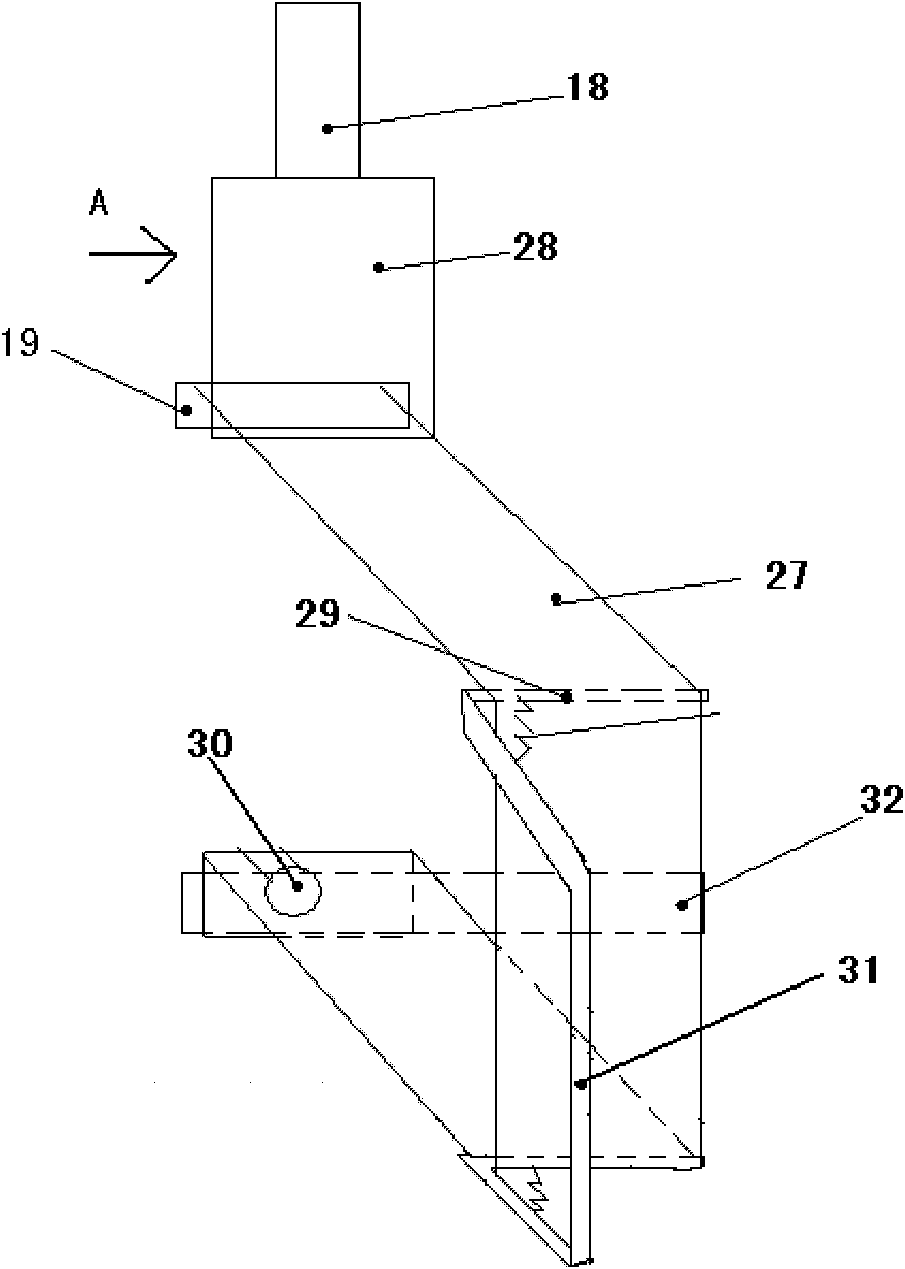

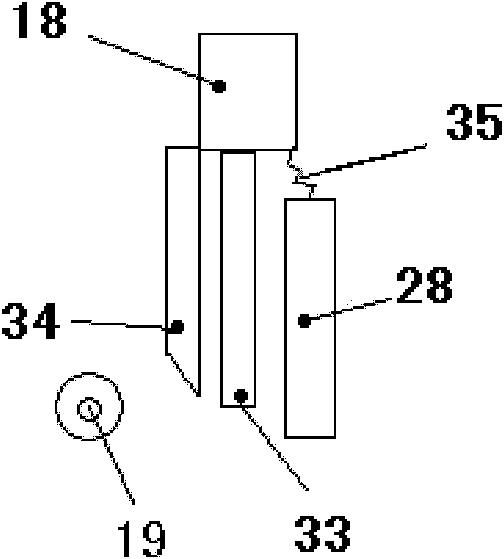

[0015] Such as Figure 1-3 , the automatic wrapping method of the lead-acid storage battery production of the present embodiment, comprises: adopting the automatic sheet feeding device to remove the preset number of positive and negative sheets from the positive sheet stack and the negative sheet stack respectively and alternately stack them one by one on a tray and form a stack of rectangular cylinders; during the process of alternately stacking the positive and negative films one by one on the support, a paper feeding mechanism is used to insert cellophane for isolation between the positive and negative films; After the preset number of positive and negative films are stacked, a packing mechanism uses plastic paper to pack the stack, and finally a wrapping mechanism wraps the stack with plastic tape.

[0016] The film support is horizontally arranged on a vertical liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com