Safety valve self-check method, system and anesthesia machine

A self-inspection system and safety valve technology, applied in respirator and other directions, can solve problems such as effective opening threshold error, inconvenient accuracy, safety hazards, etc., achieve high accuracy and reliability, improve safety, and be easy to implement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

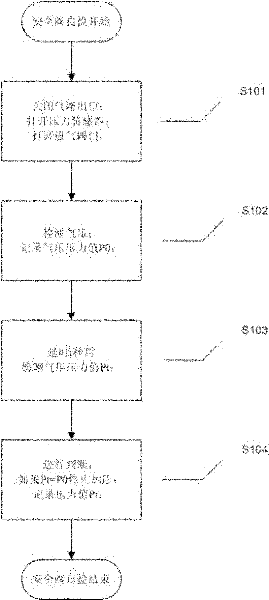

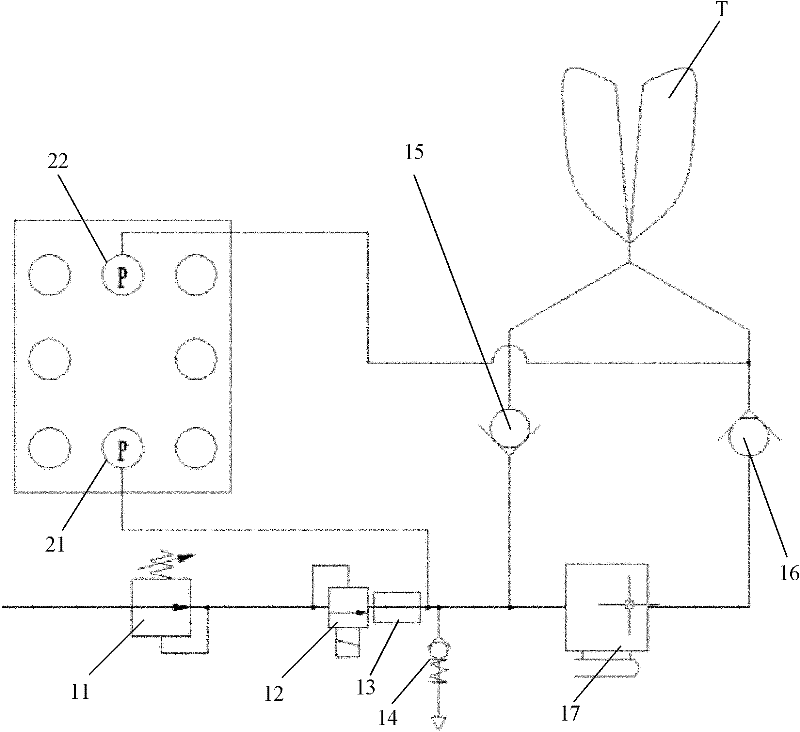

[0050] see figure 1 and Figure 4 To illustrate the safety valve self-inspection method, when the safety valve self-inspection program starts, the following steps are performed in sequence: Step S101, close the air outlet of the air circuit so that the air circuit forms a closed space with only a single air inlet, open the pressure sensor, To prepare for detection, open the intake valve, and continue to inhale air through the intake port, so that the internal pressure of the confined space continues to increase.

[0051] Step S102, detecting the air pressure inside the confined space and recording the air pressure value P0.

[0052] Step S103, re-detect the air pressure value Pt inside the confined space after t seconds have elapsed after detecting the air pressure value P0.

[0053] Step S104, judge. If Pt=P0, it indicates that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com