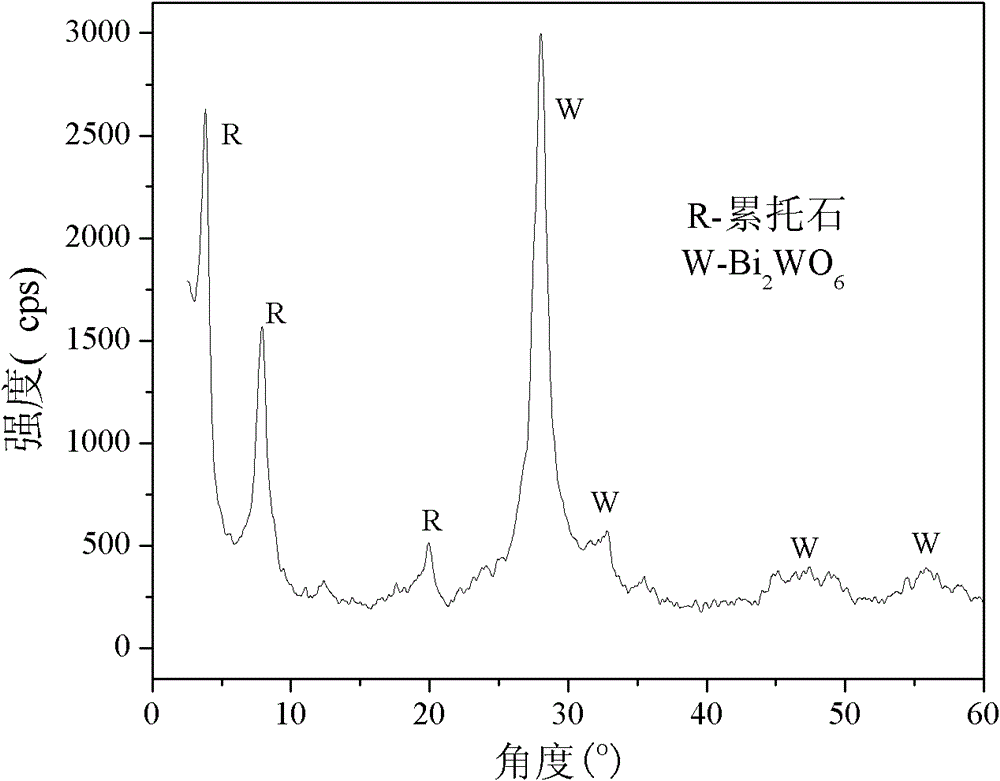

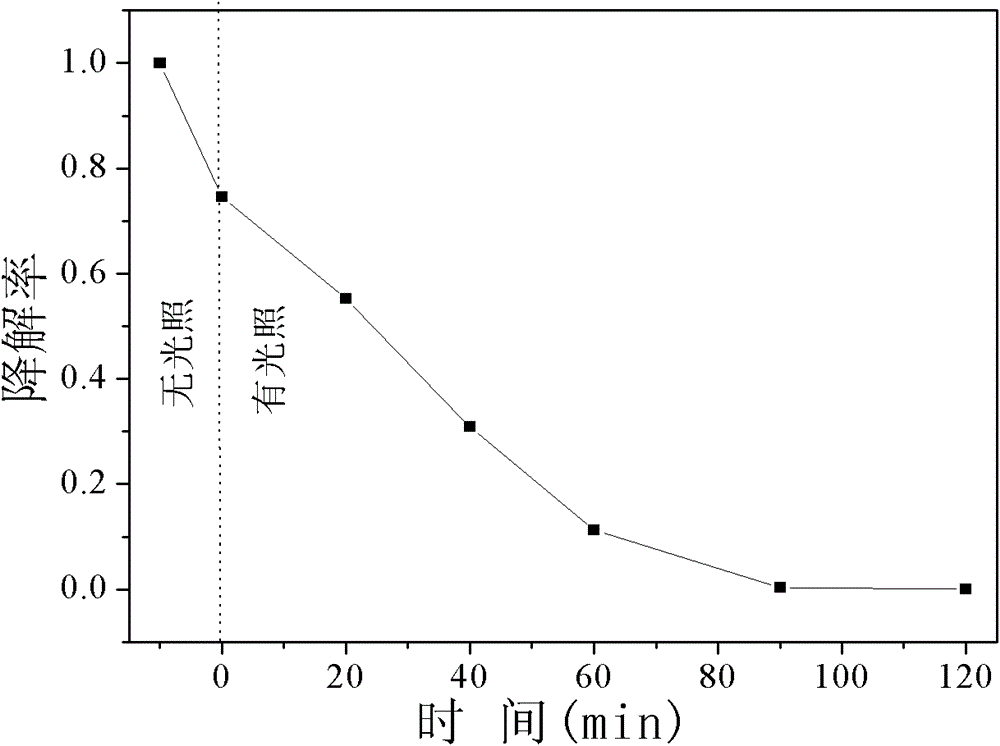

Preparation method of nanometer Bi2WO6/rectorite composite catalyst

A composite catalyst and rectorite technology, which is applied in physical/chemical process catalysts, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of small powder specific surface area, difficulty in separation and recovery, low utilization efficiency, etc., and achieve strong adsorption , high visible light activity, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A Visible Light Responsive Nano-Bi 2 WO 6 The preparation method of / rectorite composite catalyst, it comprises the steps:

[0024] 1) Take by weighing 5.6738g citric acid, be dissolved in the deionized water of 300mL, be mixed with citric acid solution, standby; Take by weighing 0.8086g (NH 4 ) 6 W 7 o 24 ·6H 2 O, dissolved in 390mL deionized water, prepared as (NH 4 ) 6 W 7 o 24 Solution, standby; Weigh 2.9104g of Bi(NO 3 ) 3 ·5H 2 O (the molar ratio of Bi ions to citric acid is 1:3), was added to the citric acid solution prepared above, and then stirred at a constant temperature of 80°C to form a white precipitate and obtain a solution containing the white precipitate; Ammonium tetraacetic acid-ammonia solution (weigh 5.2604g of ethylenediaminetetraacetic acid and dissolve in 50mL of ammonia water; the molar ratio of ethylenediaminetetraacetic acid to citric acid is 2:3), slowly add dropwise to the above solution containing white precipitate , and then co...

Embodiment 2

[0031] A Visible Light Responsive Nano-Bi 2 WO 6 The preparation method of / rectorite composite catalyst, it comprises the steps:

[0032] 1) Take by weighing 5.6738g citric acid, be dissolved in the deionized water of 300mL, be mixed with citric acid solution, standby; Take by weighing 0.8086g (NH 4 ) 6 W 7 o 24 ·6H 2 O, dissolved in 390mL of deionized water, prepared as (NH 4 ) 6 W 7 o 24 Solution, standby; Weigh 2.9104g of Bi(NO 3 ) 3 ·5H 2 O (the molar ratio of Bi ions to citric acid is 1:3), was added to the citric acid solution prepared above, and then stirred at a constant temperature of 80°C to form a white precipitate and obtain a solution containing the white precipitate; Ammonium tetraacetic acid-ammonia solution (weigh 5.2604g of ethylenediaminetetraacetic acid and dissolve in 50mL of ammonia water; the molar ratio of ethylenediaminetetraacetic acid to citric acid is 2:3), slowly add dropwise to the above solution containing white precipitate , and then...

Embodiment 3

[0038] A Visible Light Responsive Nano-Bi 2 WO 6 The preparation method of / rectorite composite catalyst, it comprises the steps:

[0039] 1) Take by weighing 5.6738g citric acid, be dissolved in the deionized water of 300mL, be mixed with citric acid solution, standby; Take by weighing 0.8086g (NH 4 ) 6 W 7 o 24 ·6H 2 O, dissolved in 390mL of deionized water, prepared as (NH 4 ) 6 W 7 o 24 Solution, standby; Weigh 2.9104g of Bi(NO 3 ) 3 ·5H 2 O (the molar ratio of Bi ions to citric acid is 1:3), was added to the citric acid solution prepared above, and then stirred at a constant temperature of 80°C to form a white precipitate and obtain a solution containing the white precipitate; Ammonium tetraacetic acid-ammonia solution (weigh 5.2604g of ethylenediaminetetraacetic acid and dissolve in 50mL of ammonia water; the molar ratio of ethylenediaminetetraacetic acid to citric acid is 2:3), slowly add dropwise to the above solution containing white precipitate , and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com