Manipulators used in the production of refrigerant tanks

A technology of manipulator and refrigerant tank, applied in the field of manipulator, can solve the problems of high labor intensity, danger and low efficiency, and achieve the effect of improving production efficiency and reducing risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

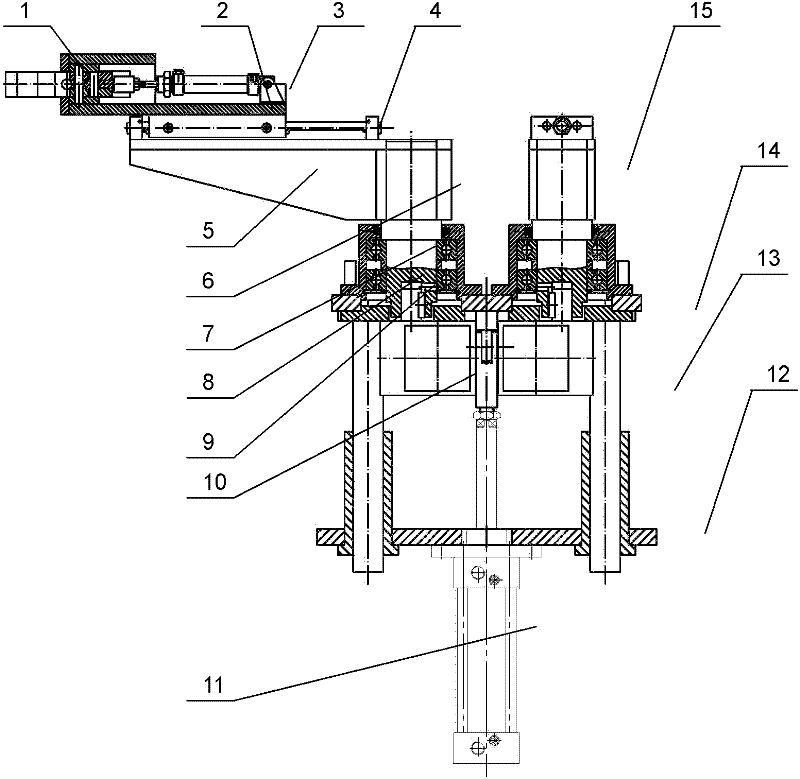

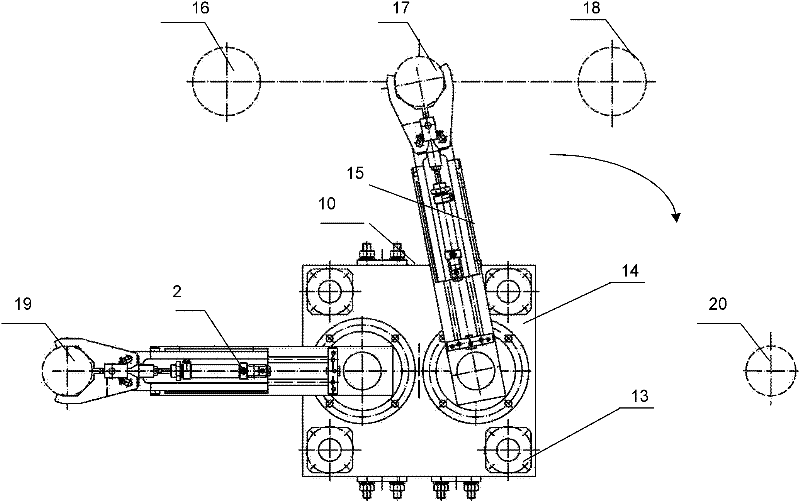

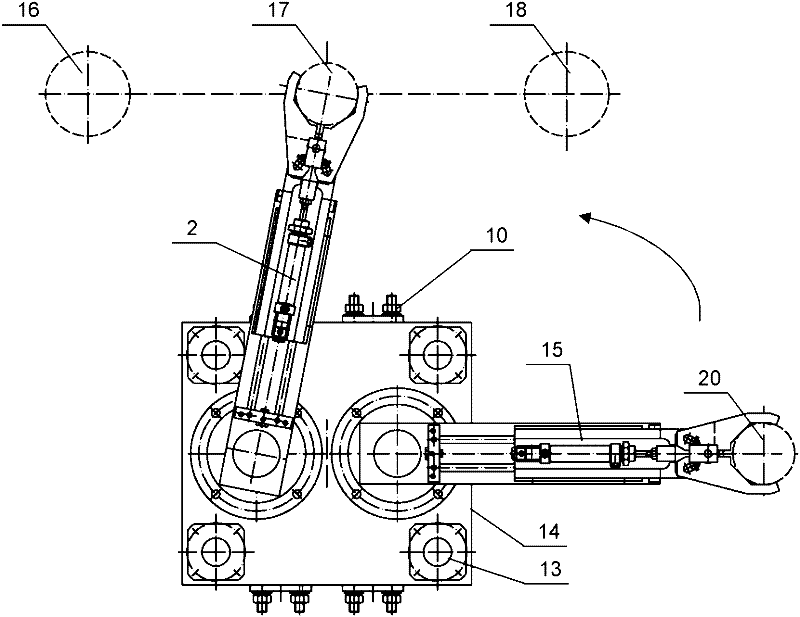

[0022] The present invention will be further described below in conjunction with accompanying drawing:

[0023] see Figure 1 to Figure 11 , a manipulator used in the production of refrigerant tanks, including a manipulator assembly, the manipulator assembly includes a feeding assembly 2 and a feeding assembly 15, the manipulator assembly consists of a gripper 1, a gripper elastic cylinder 3, a gripper telescopic cylinder 4 and Composed of swing arm 5, under the action of jaw elastic cylinder 3, the jaw can produce clamping and loosening actions to realize the clamping and loosening of the refrigerant tank; under the action of jaw telescopic cylinder 4, the jaw Two actions of extending and retracting can be produced to avoid interference with the left column 16 and the right column 18 of the punching machine. The feeding manipulator 2 is connected with the rack and pinion swing cylinder 10 through the shaft 6, driven by the rack and pinion swing cylinder 10, the feeding manip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com