Positive and negative pressure combined delivery tank

A combined type and tank-transporting technology, which is applied in the direction of conveyors, conveying bulk materials, transportation and packaging, etc., can solve the problems of time-consuming, labor-intensive, environmental pollution, low efficiency, etc., and achieve advanced technology, high degree of installation freedom, and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

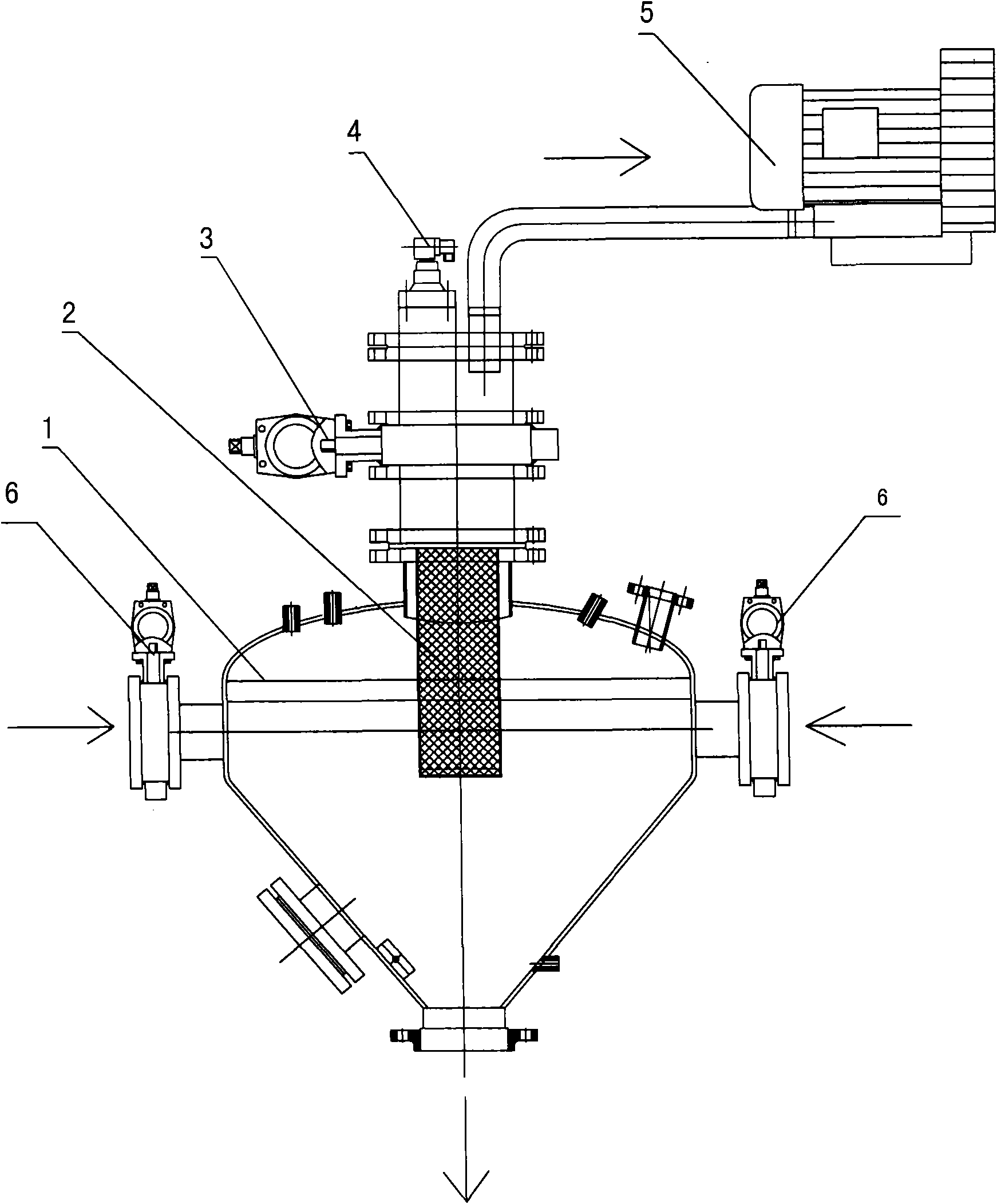

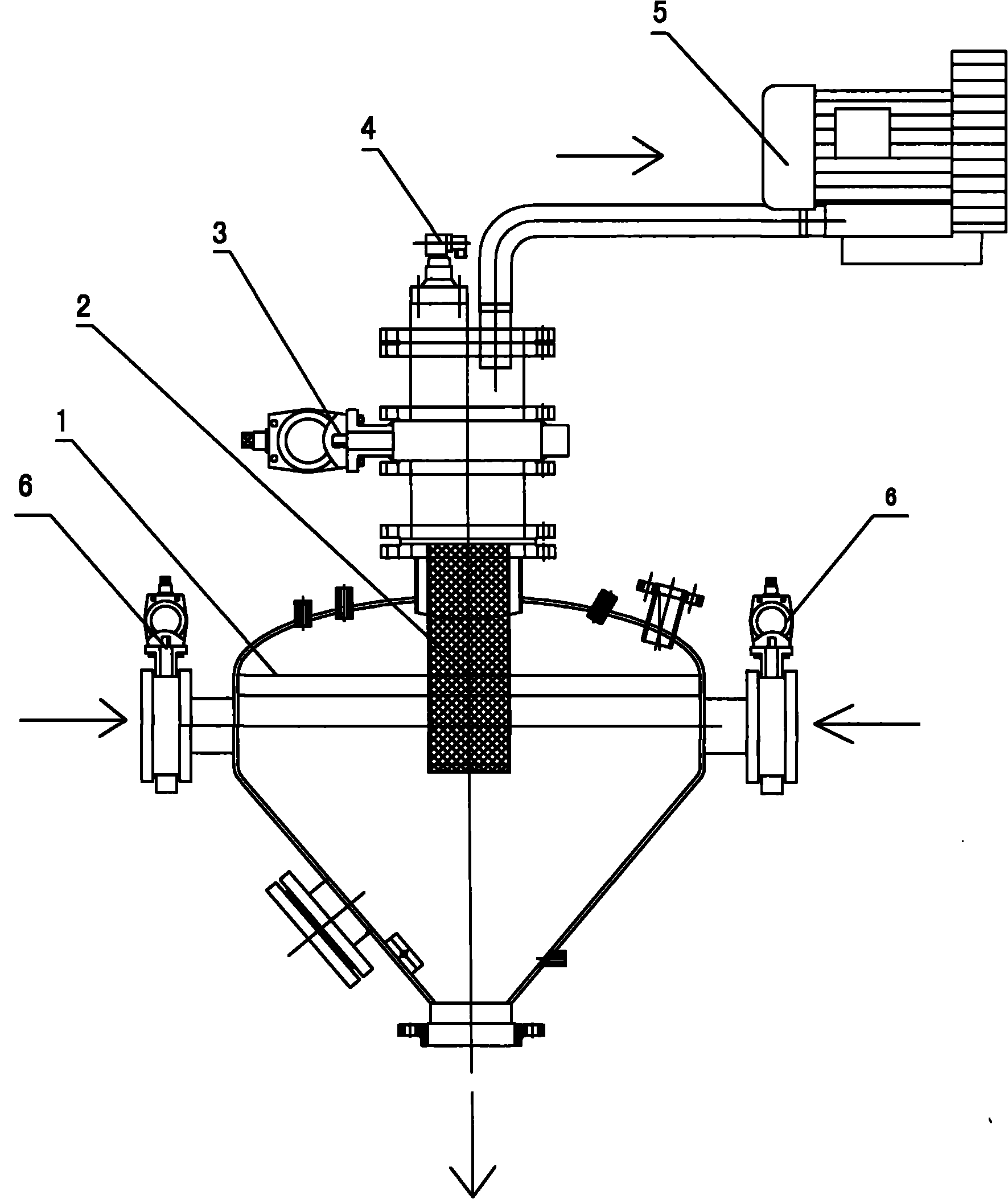

[0013] See figure 1 , the positive and negative pressure combined delivery tank of this embodiment includes: a sending tank 1, a filter element 2 located in the exhaust port on the top of the sending tank 1, a pneumatic butterfly valve 3 arranged on the exhaust port at the top of the sending tank 1, and a pneumatic butterfly valve connected to the pneumatic butterfly valve 3. The vortex suction pump 5 above, the submerged pulse solenoid valve 4 installed above the pneumatic butterfly valve 3 and connected to a high-pressure air source for blowing the adhered material on the filter element 2, and the feed material installed in the middle and upper part of the sending tank 1 The feed valve 6 on the mouth, and the suction sealing valve that is located on the discharge port at the bottom of the sending tank 1.

[0014] In order to facilitate the pressure feeding and emptying of materials, the sending tank 1 is conical.

[0015] The feed valve 6 includes a pair of symmetrical dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com