Anti-corrosive paint and application thereof

A technology of anti-corrosion coatings and auxiliary materials, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of easy cracking and falling off, threatening the safe operation of thermal power plants, and corrosive and destructive chimneys and flues.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

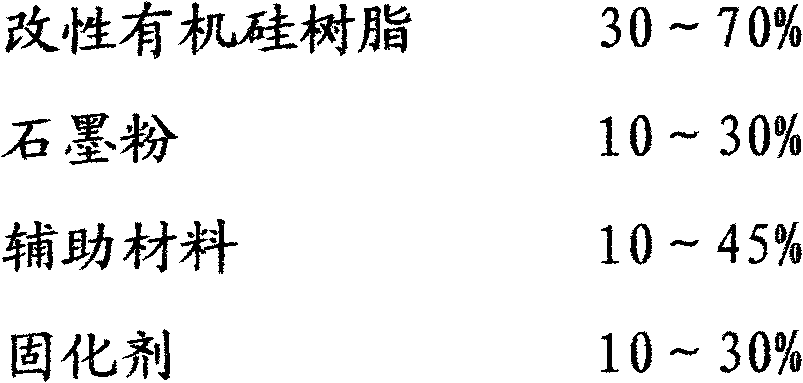

[0022] An anti-corrosion coating consisting of the following components:

[0023]

[0024] Put the resin into the dispersion cylinder, add graphite powder, filler, solvent, etc. in sequence under high-speed dispersion (about 800rpm), and through physical grinding, adjust the viscosity, etc., to meet the technical requirements of the product.

Embodiment 2

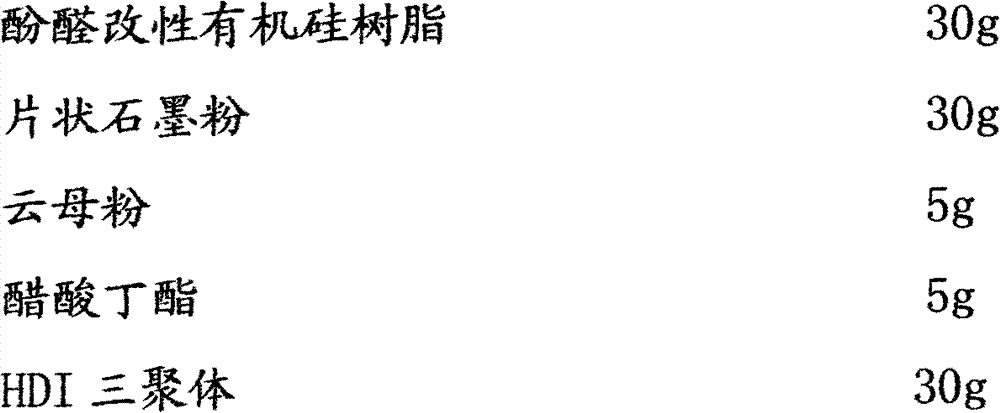

[0026] An anti-corrosion coating consisting of the following components:

[0027]

Embodiment 3

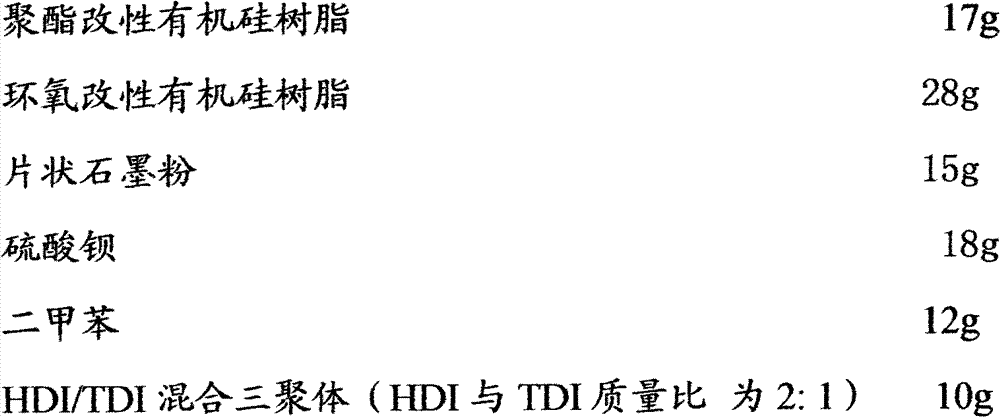

[0029] An anti-corrosion coating consisting of the following components:

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com