A kind of sand taking method and sand taking device of tailings pond

A tailings pond and sand suction pump technology, which is applied in the field of sand extraction from tailings ponds, can solve difficult-to-reach problems and achieve great social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

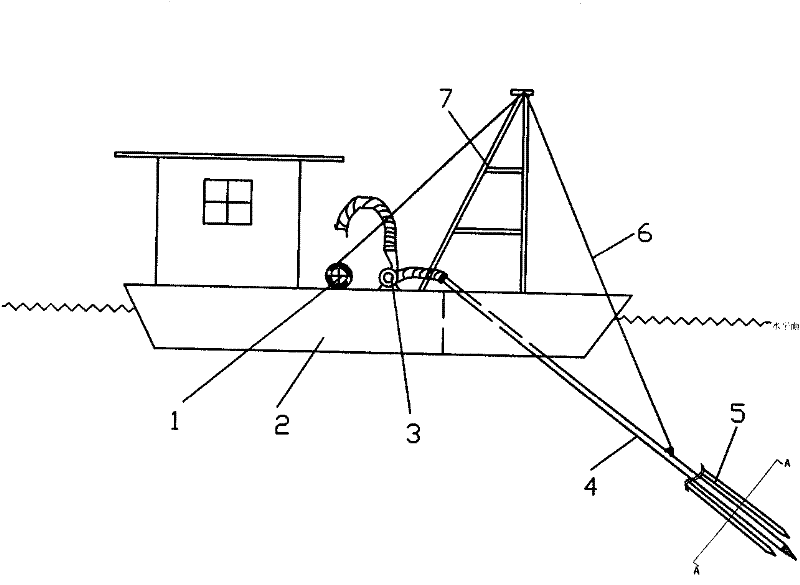

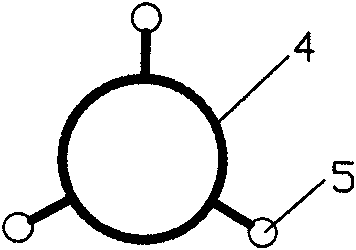

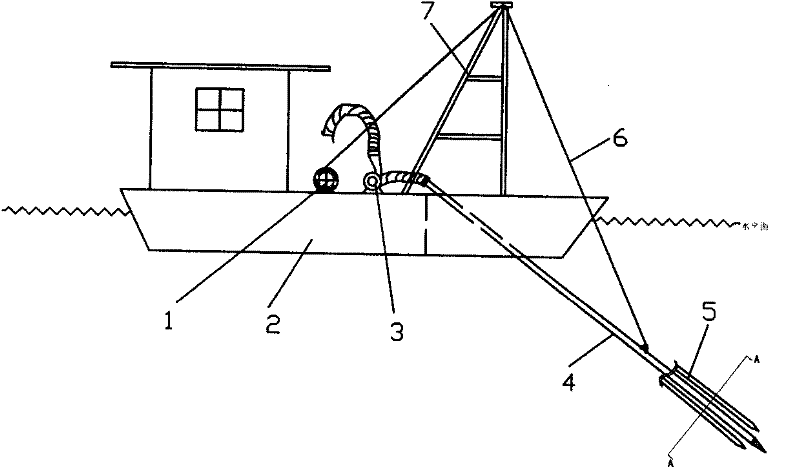

[0015] Make the sand taking device: it includes a pontoon 2, a sand suction pump 3 fixed on the pontoon 2, and a high-pressure water gun 5. The high-pressure water gun 5 is provided with three gun barrels, and the three gun barrels are fixed on the suction pipe 4 of the sand suction pump in parallel and evenly distributed. At the front end, the pontoon 2 is provided with a bracket 7 and a winch 1, the top of the bracket 7 is provided with a pulley, and the steel cable of the winch 1 passes through the front end of the pulley to connect with the suction pipe 4 of the sand suction pump, so that the winch 1 can lift the suction pipe of the sand suction pump 4 and high pressure water gun 5.

[0016] Sand extraction: place the floating boat 2 in the tailings pond, input the front end of the suction pipe 4 of the sand suction pump into the high-pressure water gun 5 to impact the tailings to make slurry, use the sand suction pump 3 on the floating boat 2 to inhale, and exit from the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com