proportional valve

A proportional valve and valve body technology, applied in the field of proportional valves, can solve the problems of complex structure of the proportional valve actuator, insufficient anti-interference ability, staying in the scheme design, etc., and achieve the effects of simple structure, good sealing performance and stable control process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

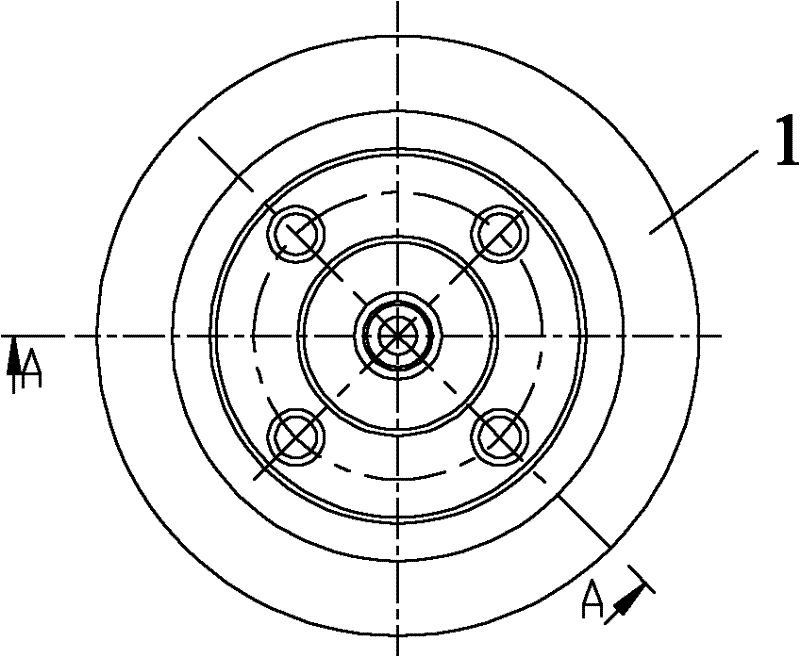

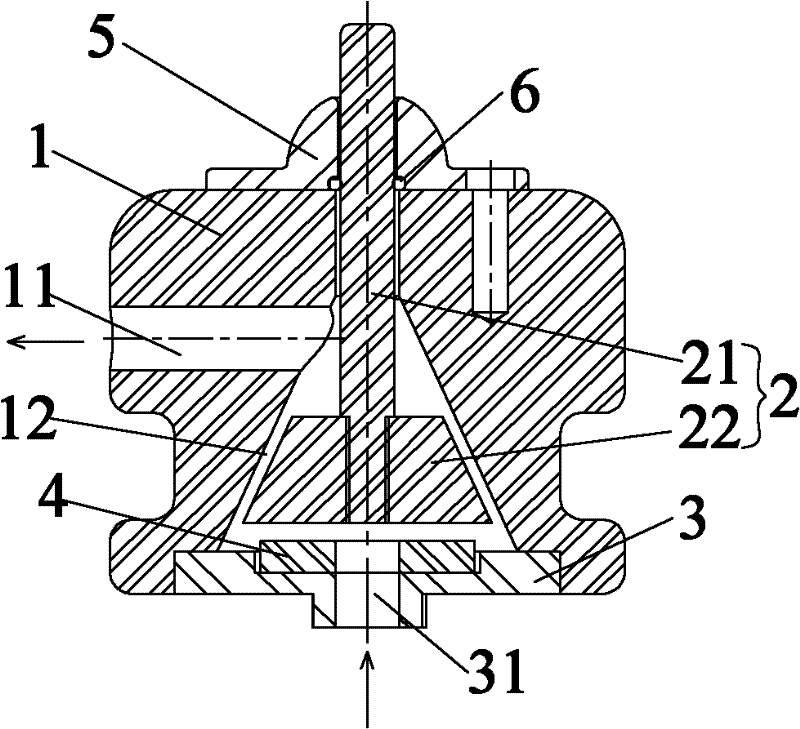

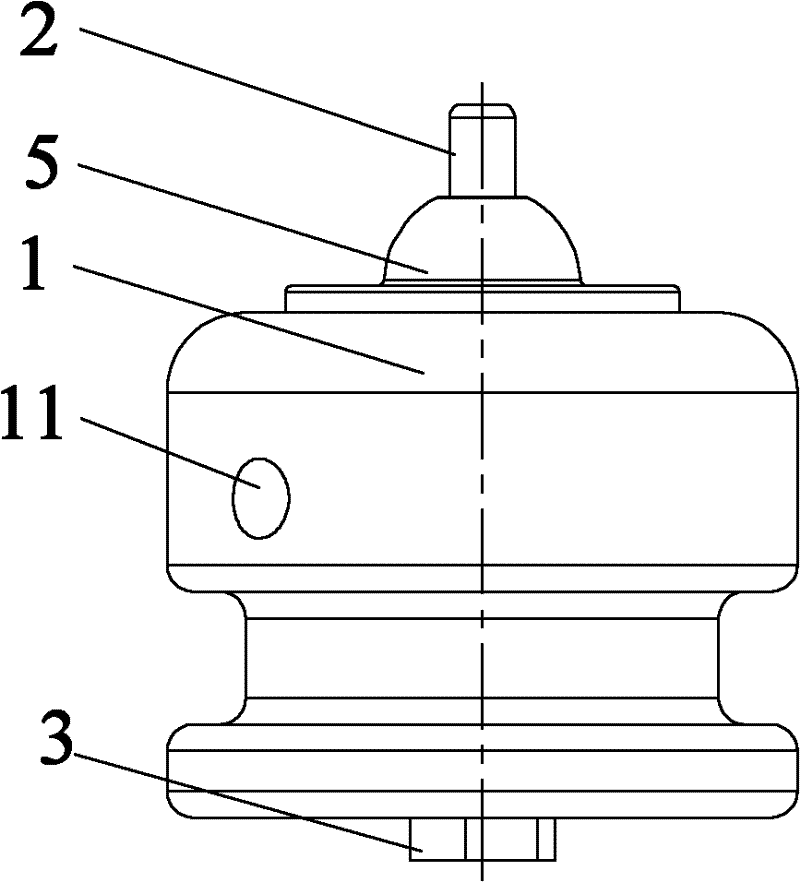

[0021] Such as figure 1 with figure 2 As shown, according to the first embodiment of the present invention, the proportional valve includes a valve body 1 and a valve core 2 disposed in the cavity 12 of the valve body 1 , and the valve core 2 and the valve body 1 are fitted with a conical surface. The valve core 2 includes a cone core 22 with a conical surface and a slide rod 21 fixedly connected with the cone core 22 and slidably arranged in the valve body 1 . A seal ring 6 is provided at the joint between the protruding end of the slide rod 21 and the upper end of the valve body 1, and a gland 5 fixedly connected to the valve body 1 is arranged outside the seal ring 6, and the gland 5 presses the seal ring 6 tightly against the valve body. The joint between the upper end of the body 1 and the slide rod 1 keeps the entire valve body in good airtightness. There is clearance fit between the slide rod 21 and the valve body 1 , and the valve core 2 is suspended in the cavity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com