A swash plate type plunger pump, a flow plate of a motor and its associated cylinder

A technology of swash plate plunger pump and distribution plate, which is applied in the hydraulic field, can solve problems such as increased internal leakage, large sliding friction power consumption, and speed restriction, and achieves improved self-priming capacity, good boosting effect, and allowable speed high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The specific implementation, features and functions of a swash plate type plunger pump, a flow plate of a motor and its matching cylinder according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

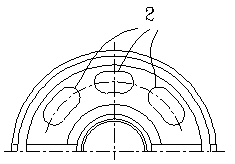

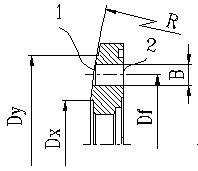

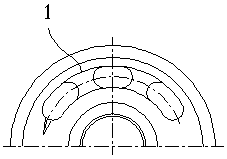

[0067] like Figure 2a-2d As shown, the valve plate and the cylinder adopt spherical flow distribution. The projection of the distribution window 3 on the front spherical side of the distribution plate on its back (plane side) is misaligned with the distribution window 4 on the back plane side, and the outer diameter D1 of the distribution window 4 on the back plane side is larger than the outer diameter d1 of the distribution window 3 on the front spherical side , the inside diameter D2 of the flow distribution window 4 on the back plane side is greater than the inside diameter d2 of the flow distribution window 3 on the front spherical side.

[0068] In order to ensure that the flat side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com