A New Type of Load Holding Valve

A load holding valve, a new type of technology, applied in the field of hydraulic valves, can solve the problems of difficult control of orifice size tolerance, high requirements for oil cleanliness, high machining accuracy, etc., to achieve good self-centering effect and clean oil Low requirement for high pressure and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

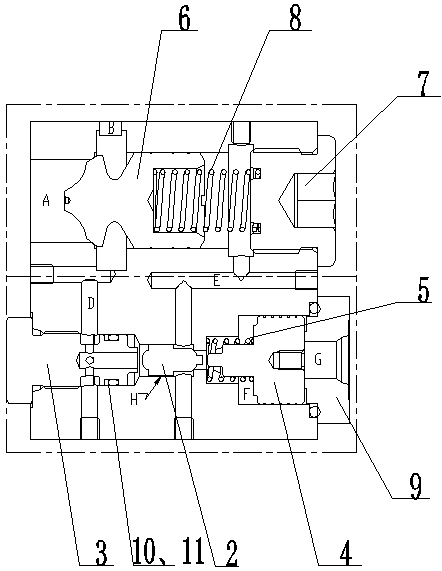

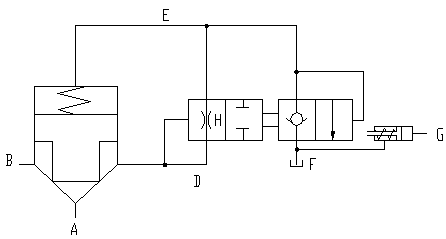

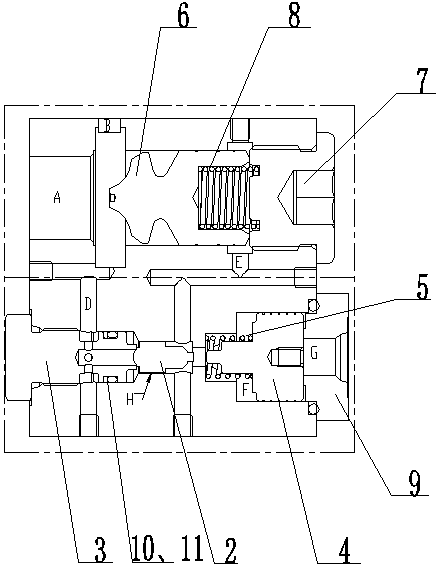

[0032] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

[0033] Such as figure 1 and figure 2 As shown in Fig. 1, a new type of load-holding valve, the valve body is provided with through step-type valve core installation holes I and valve core installation holes II, and the valve core installation holes I and valve core installation holes II are arranged in parallel. The spool installation hole Ⅰ is used to install the one-way valve part, and the spool installation hole Ⅱ is used to install the pilot control part.

[0034] The one-way valve core 6 is installed in the valve core installation hole I, and the spring chamber at the right end of the one-way valve core 6 is provided with a spring I8. A screw plug 7 is installed at the right end of the spool mounting hole I, and the spring I8 is placed between the one-way valve core 6 and the screw plug 7 . In orde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com