Suction cup and its holder

A wafer-bearing table and suction cup technology, which is used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to achieve accurate and reliable positioning of wafers, accurate and reliable positioning, and more uniform adsorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

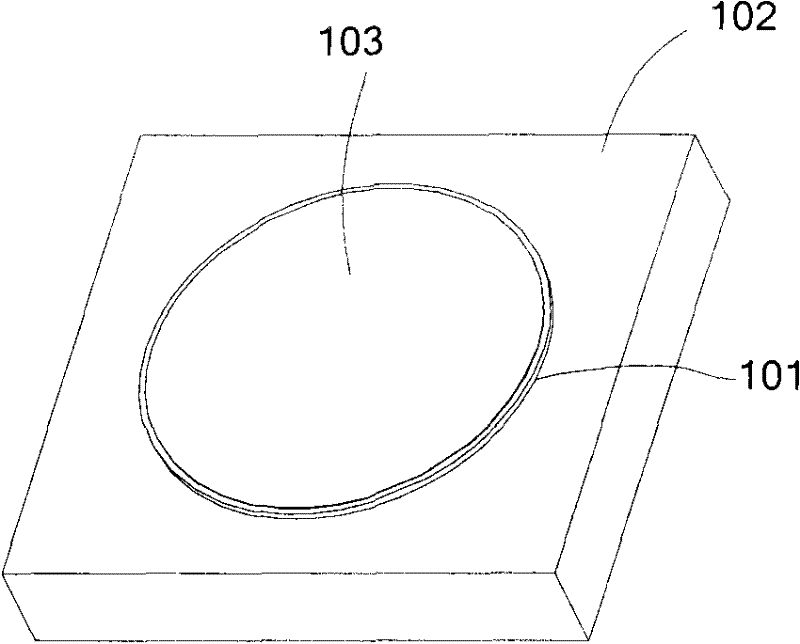

[0019] Figure 1a It is a structural schematic diagram of the wafer stage module carrying wafers.

[0020] The wafer stage module mainly includes a suction cup 101 and a square mirror 102, where the wafer 103 is carried on the suction cup 101, and the suction cup 101 is circular and fixed on the square mirror 102 by vacuum, electrostatic adsorption or other methods. The upper surface of the square mirror 102 is mainly used to carry the suction cup 101 and the wafer 103 , and its lower surface is connected with a multi-degree-of-freedom actuator for adjusting its pose, thereby completing the positioning of the wafer 103 .

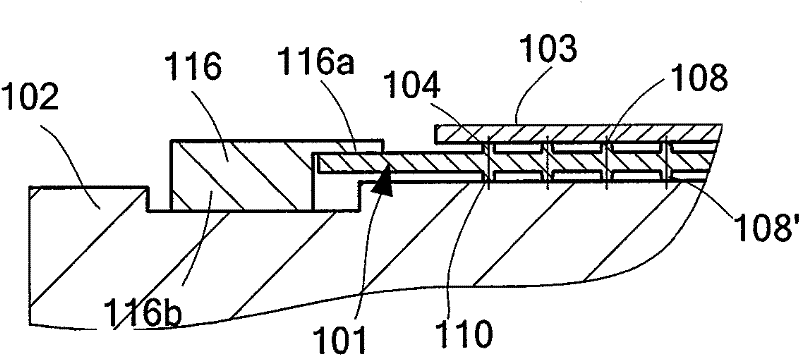

[0021] Figure 1b yes Figure 1a An exploded schematic diagram of the wafer stage module in .

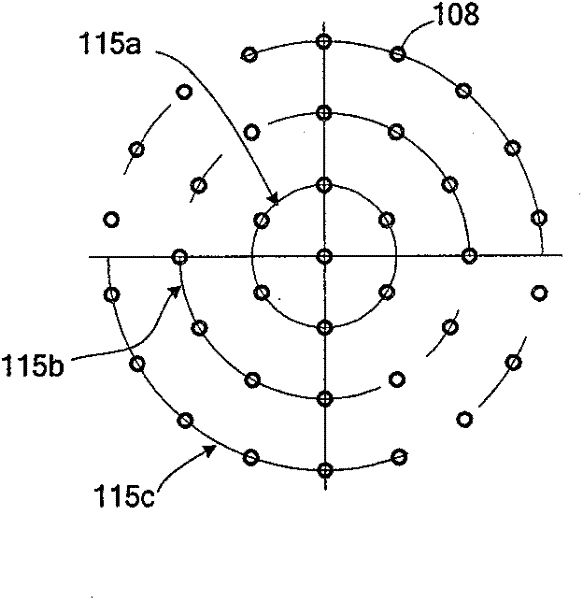

[0022] The present invention is based on the principle of vacuum adsorption. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com