Adaptive led drive power supply

An LED driving and self-adaptive technology, applied in electric light source, light source, electric light circuit layout, etc., can solve the problems of the inability to exert the advantages of LED lighting, and achieve humanized operation, strong controllability, and reduced output ripple. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

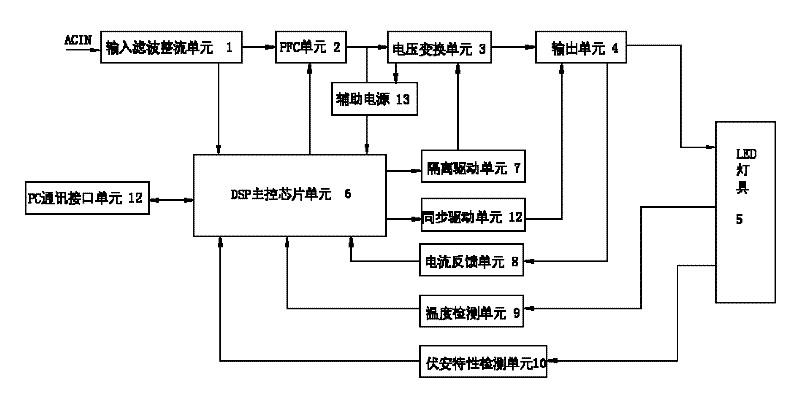

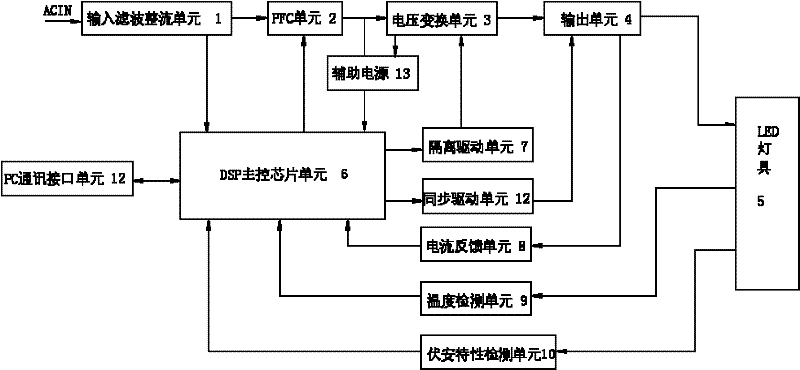

[0029] See figure 1 , the adaptive LED drive power supply of this embodiment includes: input filter rectification unit 1, PCF unit 2, voltage conversion unit 3, output unit 4, DSP main control chip unit 6, isolation drive unit 7, current feedback unit 8, temperature A detection unit 9 , a volt-ampere characteristic detection unit 10 , a synchronous drive unit 11 , a PC communication interface unit 12 and an auxiliary power supply unit 13 .

[0030]The input filtering and rectifying unit 1 is connected to the input terminal of the power supply. The PFC unit 2 is connected to the output terminal of the input filter rectifier unit 1 . The voltage conversion unit 3 is connected to the output end of the PCF unit 2 . The output unit 4 is connected to the output terminal of the voltage conversion unit 3 . The output end of the output unit 4 is connected with the LED lamp 5 . The DSP main control chip unit 6 sends out a PWM pulse width modulation signal to control the isolated dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com