Cloth attaching machine

An applicator and applicator technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as poor adhesion, waste of double-sided tape and friction cloth, time-consuming and labor-intensive, and solve errors and inconsistencies. , the effect of improving quality and life, reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

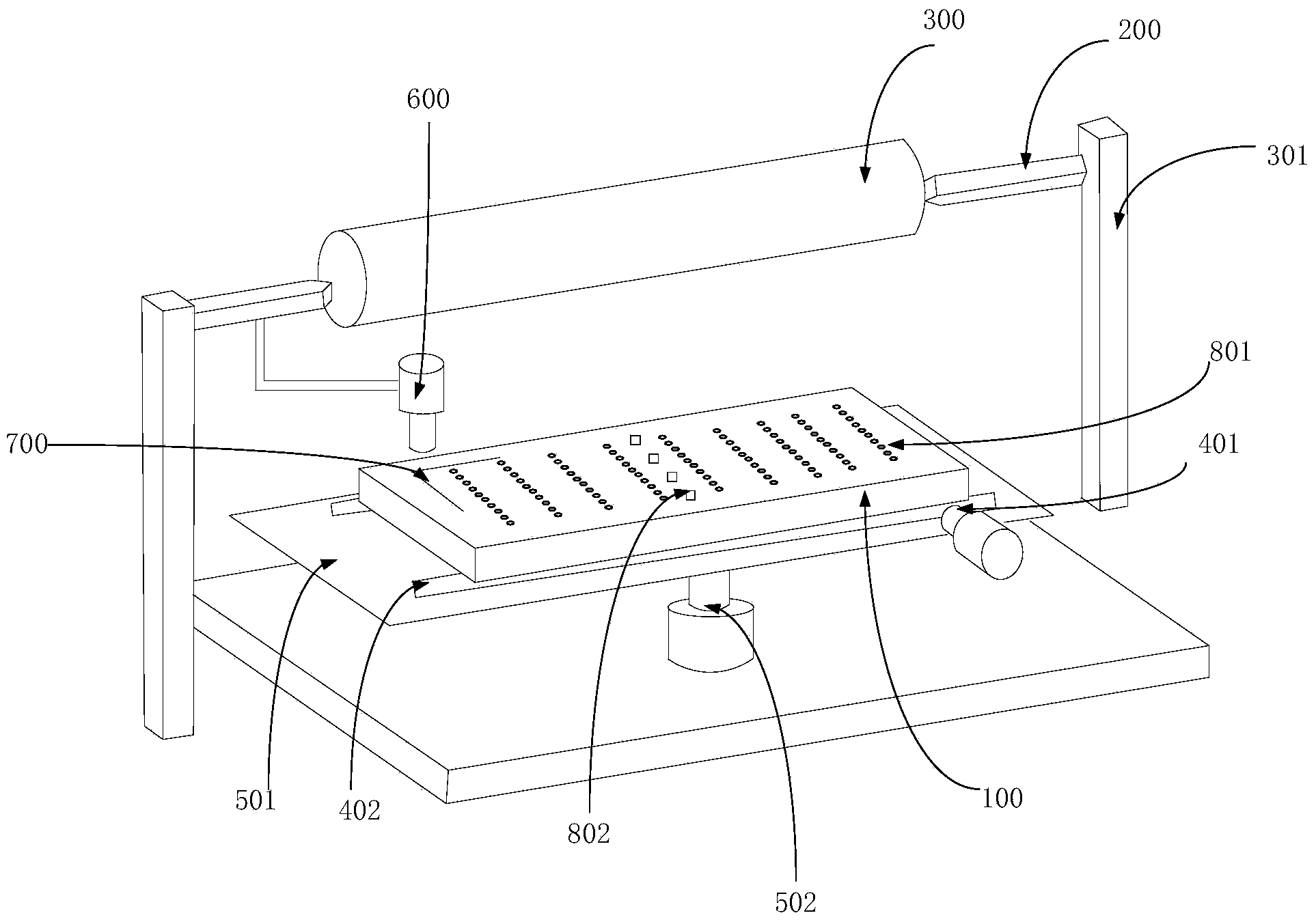

[0050] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0051] Aiming at the problem of large alignment errors and low efficiency in the prior art that requires manual alignment, the present invention provides a cloth applicator that can realize automatic and accurate alignment, improve alignment accuracy, and improve production efficiency.

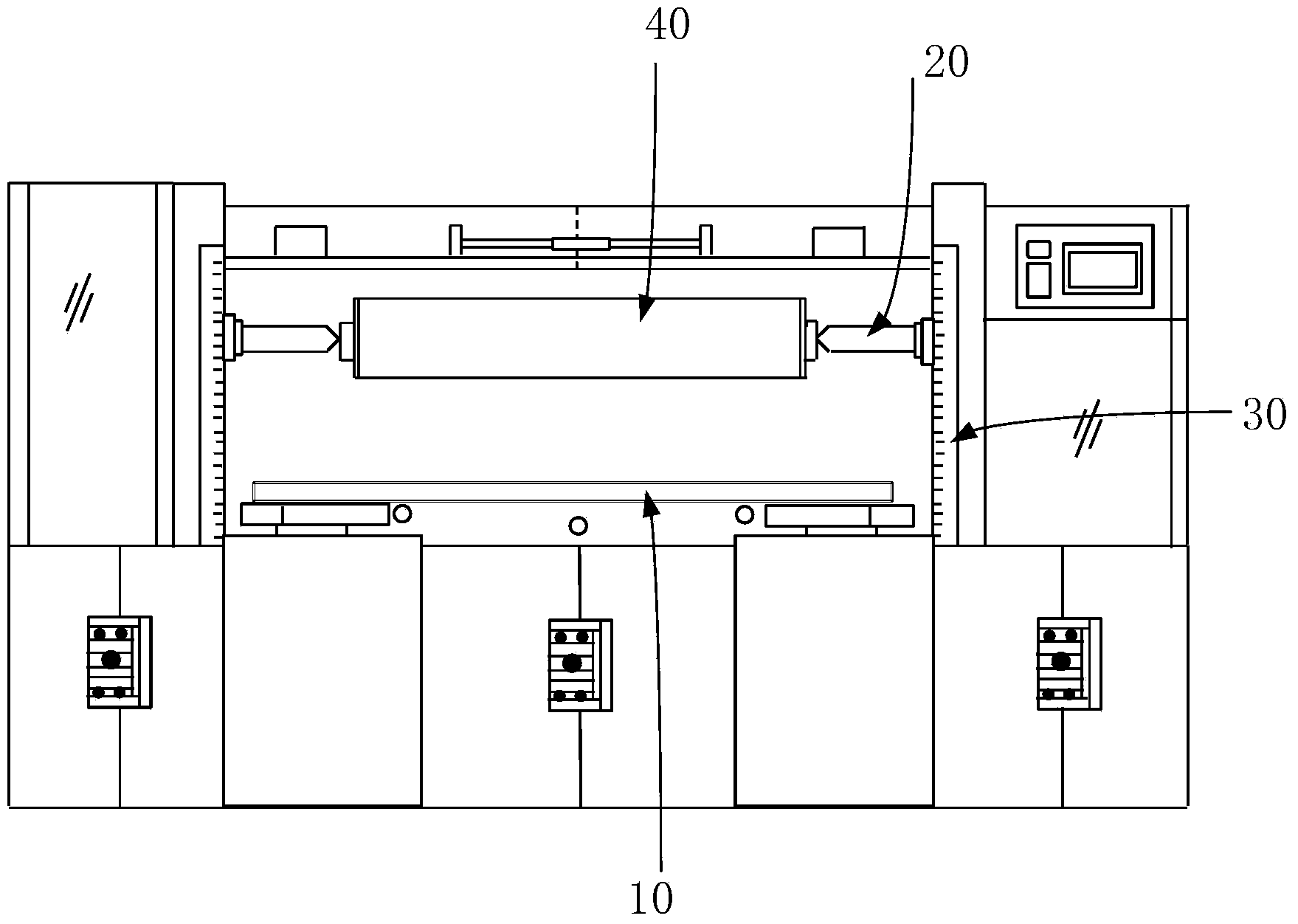

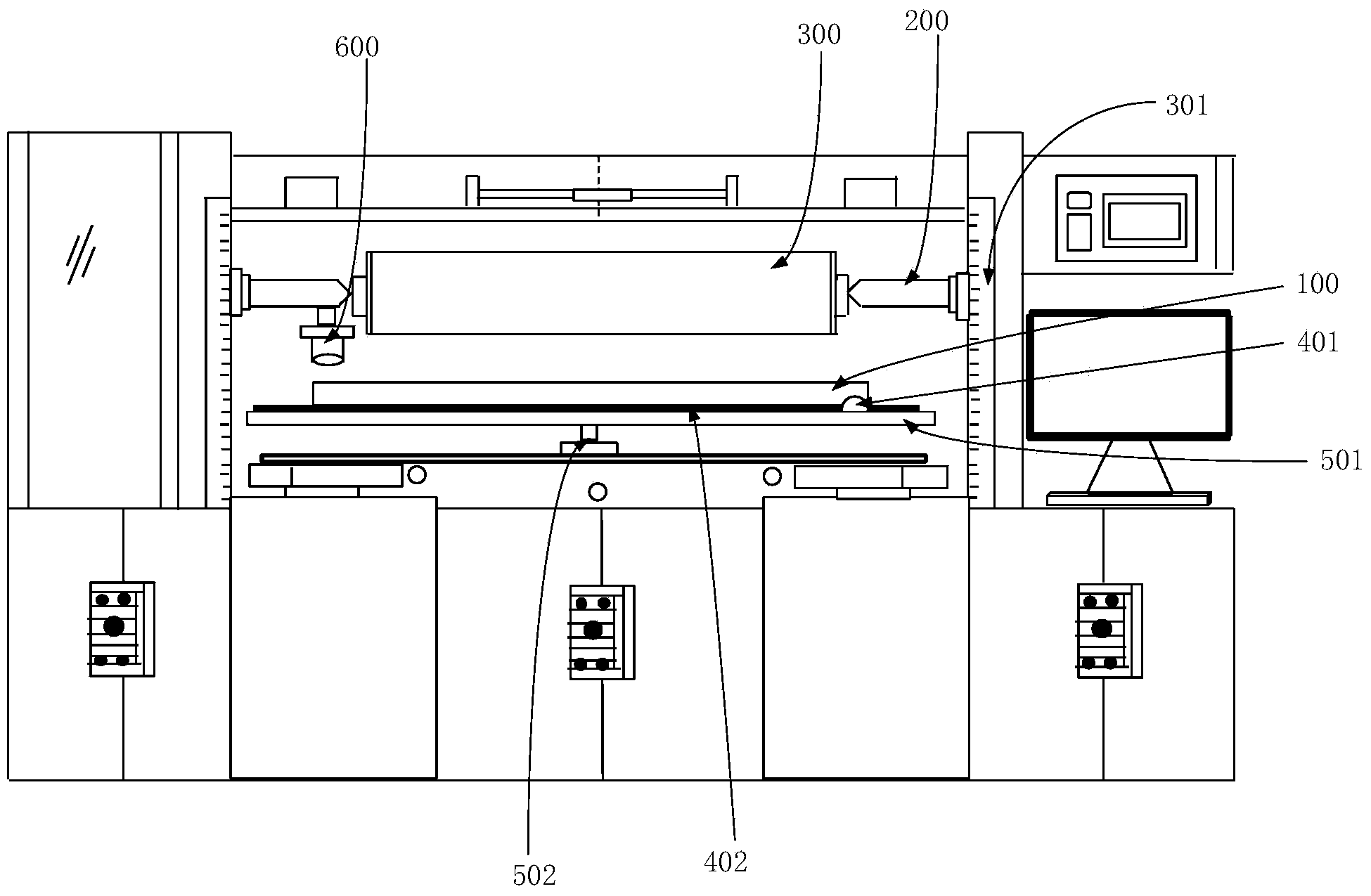

[0052] like figure 2 and image 3 As shown, the patching machine provided by the present invention includes:

[0053] The movable abutment 100 is used to place friction cloth and double-sided tape;

[0054] The movable clamping mechanism 200 is arranged above the base 100, and is used to clamp and fix the roller 300 to be pasted;

[0055] The roller driving mechanism 301 is used to move the clamping mechanism 200 to move the rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com