Speed changing air chamber hole seeding apparatus

An air cavity and hole sowing technology, which is applied in the direction of single seed planters and planter parts, can solve the problems that have not been substantially solved, and it is difficult to ensure the stability of negative pressure in the negative pressure cavity, so as to improve the seed collection rate, The effect of improving quality and stability and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

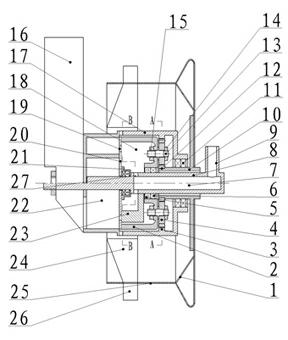

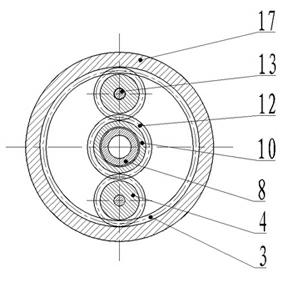

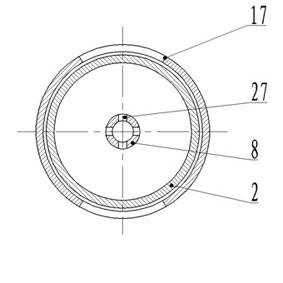

[0010] The features of the present invention and other related features are further described in detail below in conjunction with the accompanying drawings and specific embodiments:

[0011] as attached Figure 1-3 Schematic, the labels in the figure respectively indicate: 1—filming wheel, 2—air cavity, 3—internal gear, 4—air cavity gear, 5—sealing ring, 6—bearing, 7—negative pressure channel, 8—roller Main shaft, 9—negative pressure tube, 10—sleeve (gear bearing seat), 11—bearing, 12—central gear, 13—air chamber gear shaft, 14, 15—nut, 16—kind box, 17—internal tooth bracket , 18—negative pressure chamber, 19—seeding hole, 20—seeding tray, 21—bearing seat, 22—seeding chamber, 23—air-tight block, 24—inoculation box, 25—planting drum, 26—duck beak, 27—negative pressure through hole.

[0012] as attached figure 1 , 2 , 3, the present invention mainly comprises hole sowing cylinder 25, lamination wheel 1, negative pressure seed picker, drum main shaft 8, cooperates by bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com