Suspension spring automatic production process

A technology for automatic production of suspension springs, which is applied in the field of spring processing, can solve problems such as inapplicable processing of suspension springs, and achieve the effect of realizing full automation and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

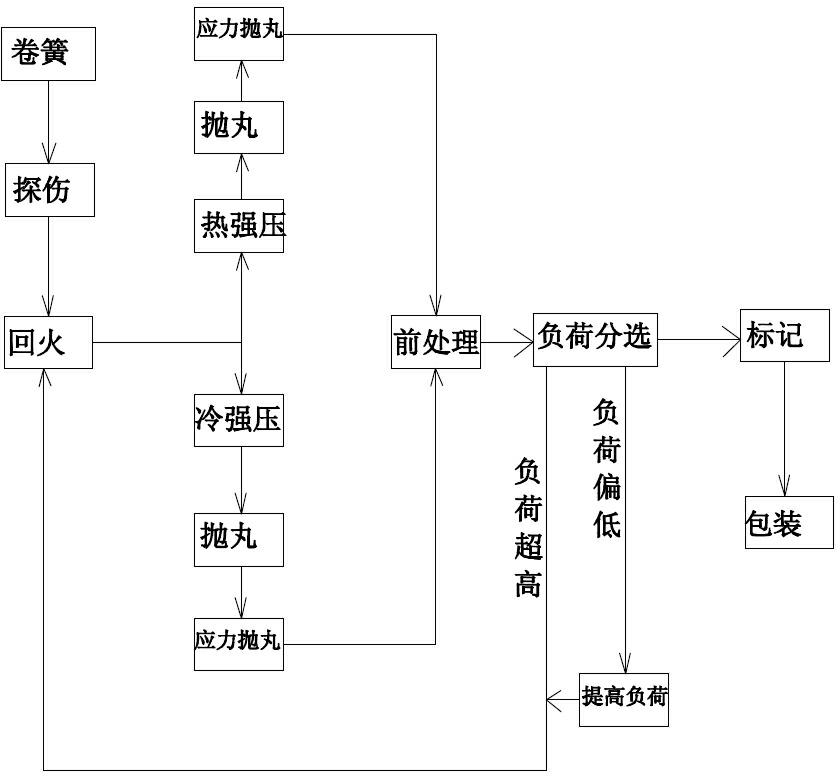

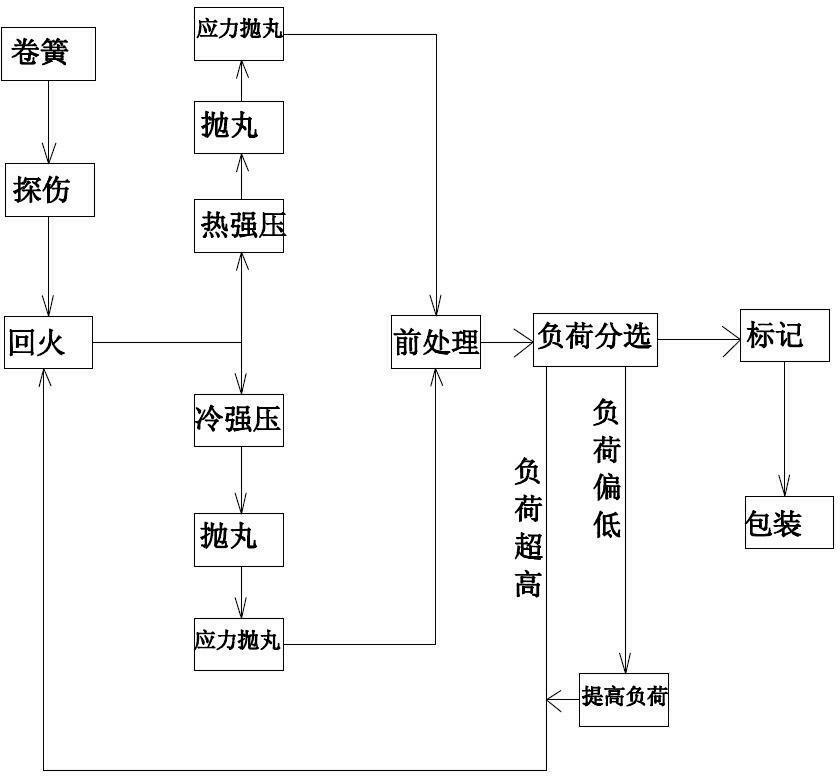

[0023] Embodiment: a kind of suspension spring automatic production technique (see attached figure 1 ), including the following steps: (1) Select the material according to the suspension spring load requirements and coil the spring on the automatic numerical control spring coiling machine. The angle is controlled by the computer when coiling the spring. 5000N is the second type of load, and then the coil spring is automatically and fully inspected by the flaw detector, and sorted according to the flaw detection results. If there is no defect after the flaw detection, it will enter the next process. If a defect is found after the flaw detection, the follow-up processing process is determined according to the defect level, including scrapping and returns;

[0024] (2) The controller receives the signal from the sensor to control the automatic feeder. According to the principle of the same batch of materials and the same load, the same batch of coil springs is transported to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com