manual wood splitter

A wood splitter and manual technology, applied in the direction of wood splitting devices, wood processing equipment, manufacturing tools, etc., can solve the problems of inconvenient wood splitting work, lower production efficiency, no energy supply such as electric energy, etc., and achieve easy transportation and carrying, The effect of short transmission distance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

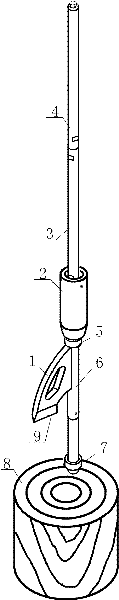

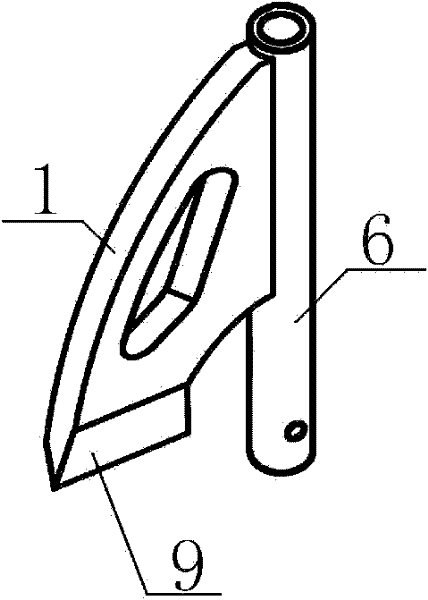

[0019] Figure 1 to Figure 3 Shown in is the manual wood splitter of the present invention. The wood splitter comprises an ax head 1, a hammer head 2 and a guide rod 3, the shape of the end face of the ax head 1 is triangular, and the hammer head 2 is a cylinder. The side of the ax 1 is provided with a guide hole 6, and the bottom of the ax 1 is provided with an ax blade 9 towards the side of the base 8, and the ax blade 9 is provided with a gap at the side connection with the guide hole 6, and the gap is shortened by setting the gap. The length of the ax blade 9, thereby improving the impact strength of the ax blade 9. The top of the guide hole 6 is provided with a tup 2, the tup 2 is provided with a guide hole, the guide rod passes through the guide hole 6 of the tup 2 and the guide hole 6 of the ax, and the end of the guide rod is fixed on the base 8 simultaneously, the ax 1 and the ax The tup 2 can slide up and down along the guide rod, and now a guide rod only needs to ...

Embodiment 2

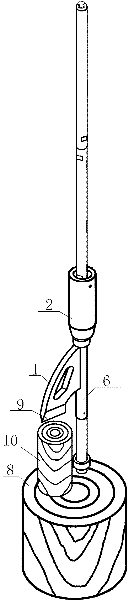

[0023] The base may not be provided in the manual wood splitter, and at this time, the end of the guide rod is directly fixed on the ground, and the side of the ax head facing the ground is provided with an ax blade.

[0024] Others are the same as embodiment 1.

Embodiment 3

[0026] Such as Figure 4 As shown, two parallel guide holes or guide grooves 6 are provided on the side of the ax head 1 . The top of the guide hole or the guide groove 6 is respectively provided with a hammer, and the hammer is provided with a guide hole or a guide groove, and the manual wood splitter is provided with two parallel guide rods, and the two guide rods pass through the corresponding ax head and the hammer head respectively. Pilot holes or slots, the ends of which are fixed to the ground or base.

[0027] Also can be provided with three or more parallel guide holes or guide grooves on the side of described axe, the top of each guide hole or guide grooves is respectively provided with hammer head, and hammer head is provided with guide holes or guide grooves, and guide bar respectively Through the guide hole or guide groove of the hammer head and the guide hole and guide groove of the axe, the end of the guide rod is fixed on the ground or the base.

[0028] Othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com