Automatic degumming method and device for multi-wire cutting of monocrystal/ polycrystalline silicon wafer

A polysilicon wafer and multi-wire cutting technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, work accessories, etc., can solve the problems of easy edge chipping and chipping on the adhesive surface, and achieves convenient application, obvious effect, and method Feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

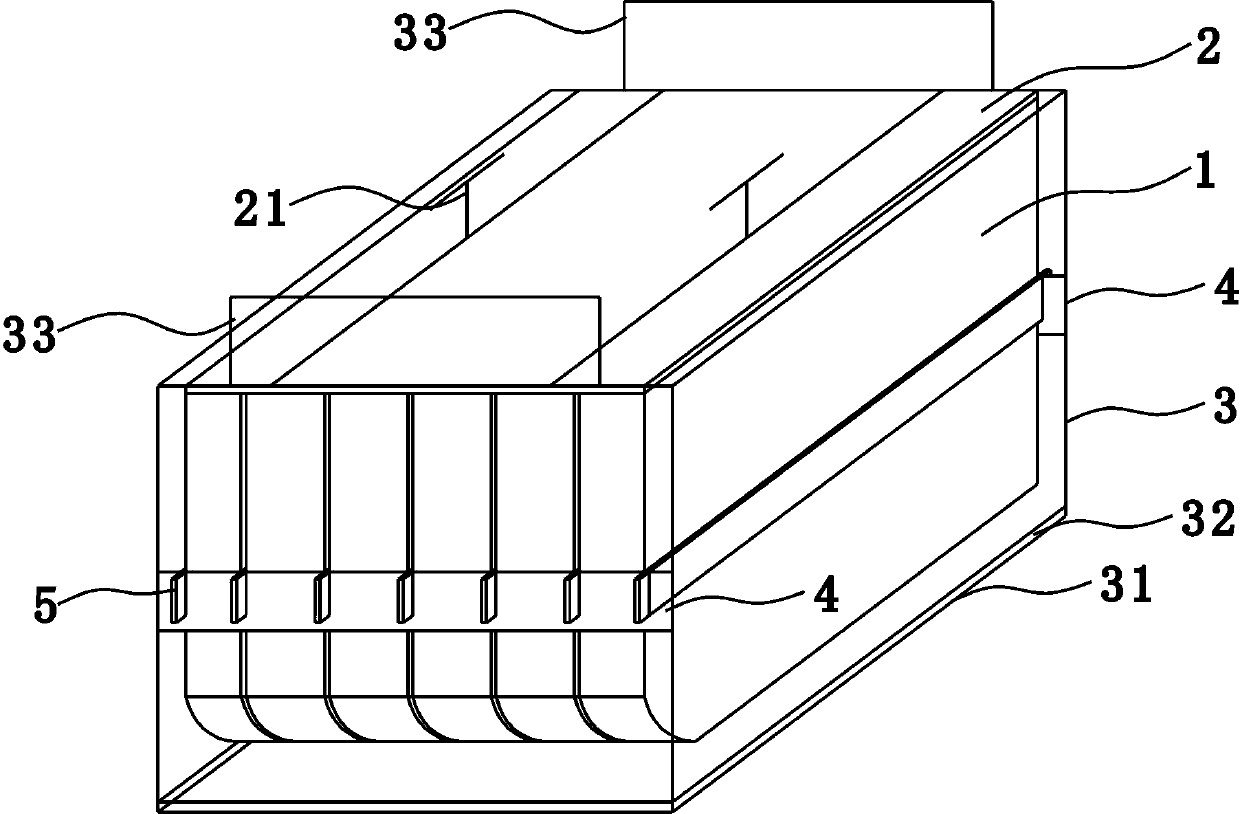

[0026] The device and method of the present invention will be further described below in conjunction with the accompanying drawings.

[0027] see figure 1 , this implementation case includes the workpiece (silicon wafer) 1 to be degummed on the glass strip of the connecting plate 2, and the bearing frame 3 that can accommodate the suspended workpiece (silicon wafer) 1. The bearing frame 3 includes a bottom plate 31, which is respectively arranged on the front The baffles 4 that cooperate with the workpiece (silicon wafer) 1 on the side and rear sides, the two baffles 4 on the front side and the rear side are provided with sheet-shaped positioning inserts 5 inserted in the workpiece (silicon wafer) 1 at intervals, and connecting plates 2 Suspended on the bearing frame 3, bonded to the connecting plate 2 glass strips, the bottom of the workpiece (silicon wafer) 1 to be degummed is suspended relative to the bottom plate 31, and the bottom plate 31 is laid with a buffer layer for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com