Film double-sided automatic positioning die-cutting gluing method

An automatic positioning and self-positioning technology, used in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc. Fitting and other problems, to achieve the effect of large size change, reduce the loss of raw materials, and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

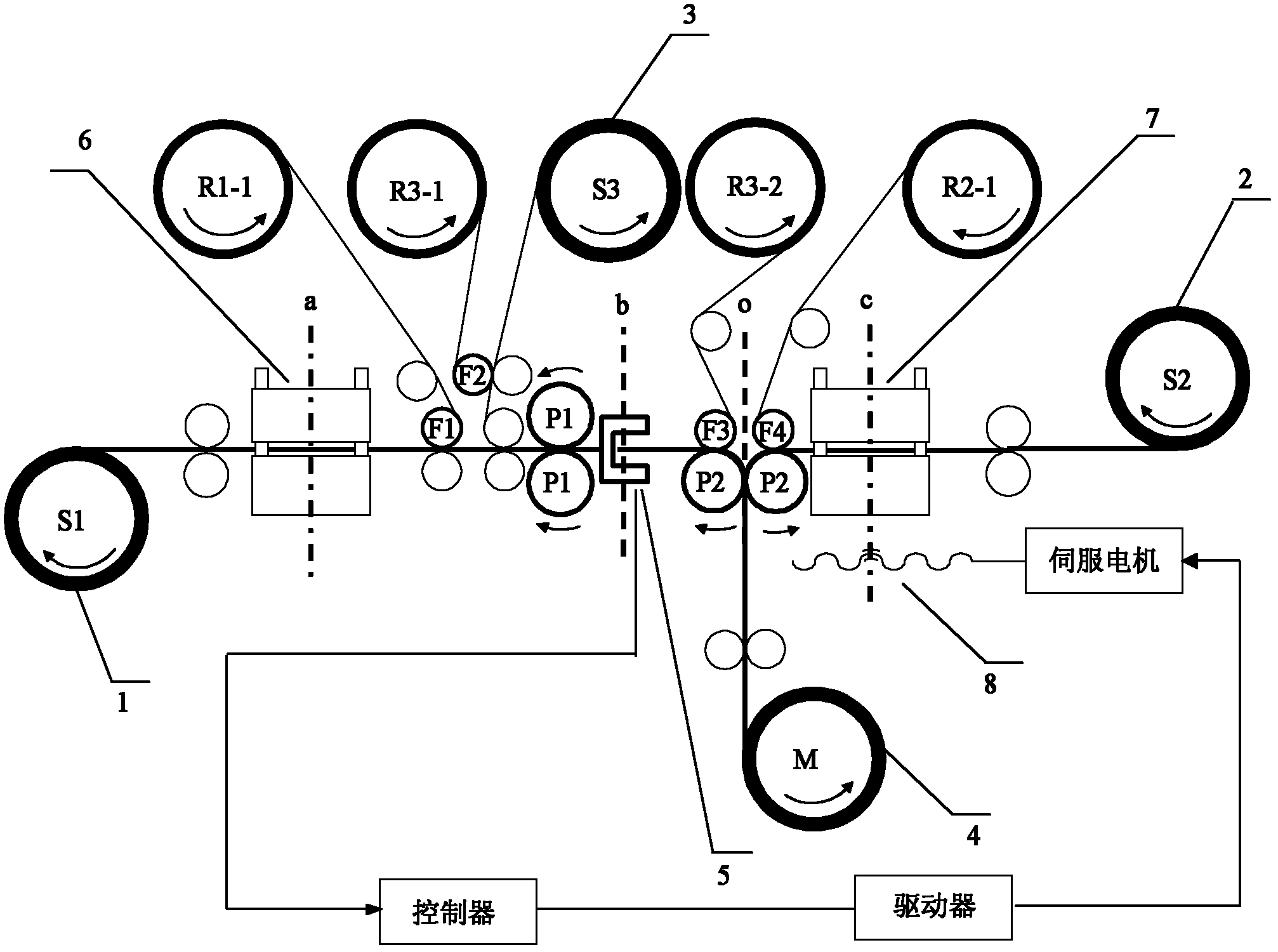

[0055] In this embodiment, according to the process flow of the double-sided self-positioning and laminating method of the film, the specific implementation of the double-sided self-positioning and laminating operation of the film is as follows:

[0056] At one station, the first die-cutting die 6 punches the application film 1, cuts off the upper two layers of the application film 1, and the middle film (ie the application film) is punched into a window. In the figure a is the first The centerline of the punching die. At the position of the color mark sensor 5, there is a window that has been punched at the previous station on the sticking film 1 .

[0057] The color mark sensor 5 detects the displacement between the actual window mark line on the film 1 and the detection reference line b (that is, shifts to the right). The displacement signal is processed by the controller in the control system and sends a control signal to the driver. The servo The motor drives the screw t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com