A multi-purpose single arm portal crane

A crane, multi-purpose technology, applied in the direction of cranes and other directions, can solve problems such as the rationality of the force of the metal structure affecting the crane, the overall stability of the crane, the rise of the center of gravity of the single-arm gantry crane, and the inability to adapt to the crane grab operation. , to achieve the effect of improving dynamic performance and working stability, improving the stability of the whole machine, and increasing the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

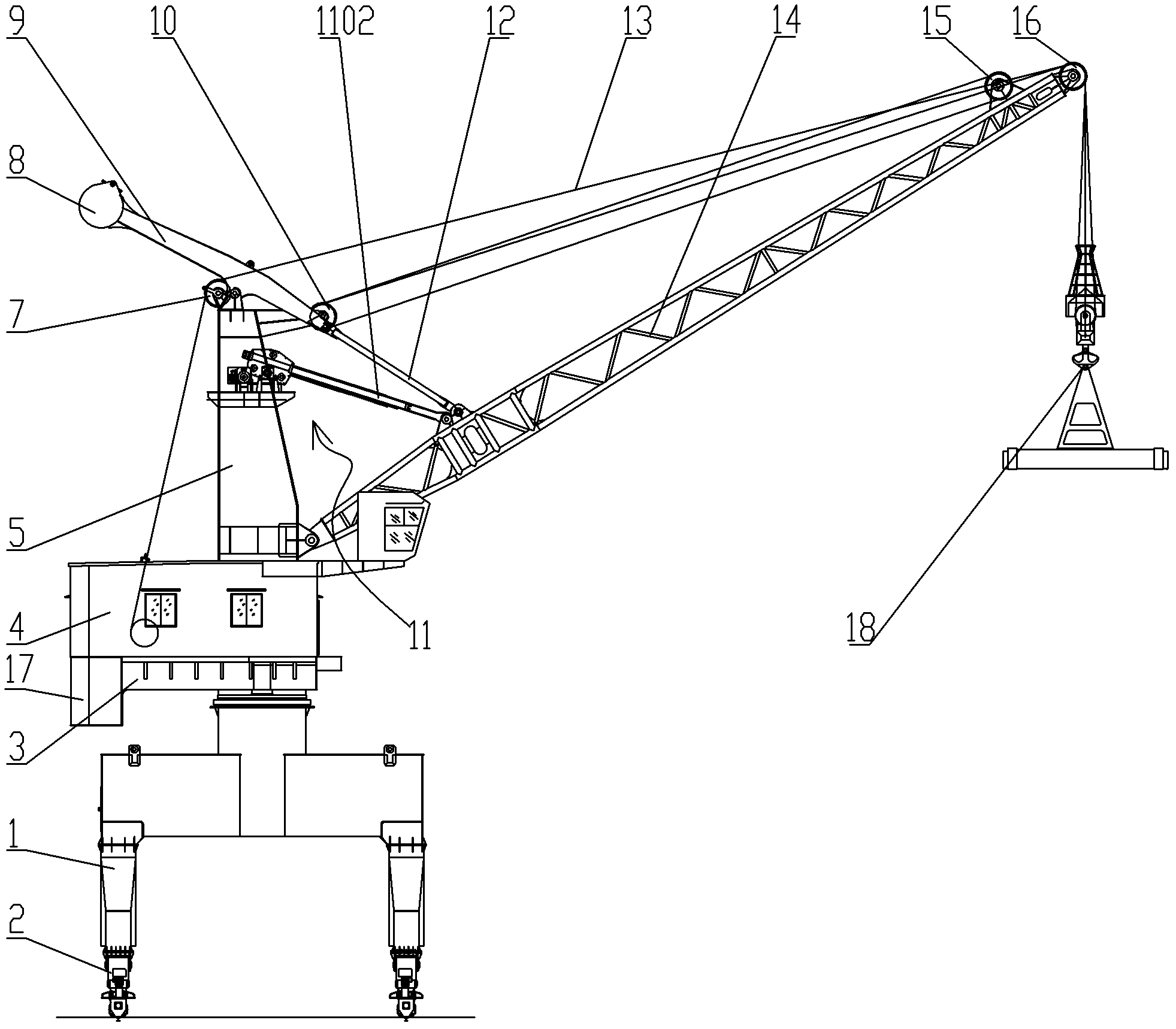

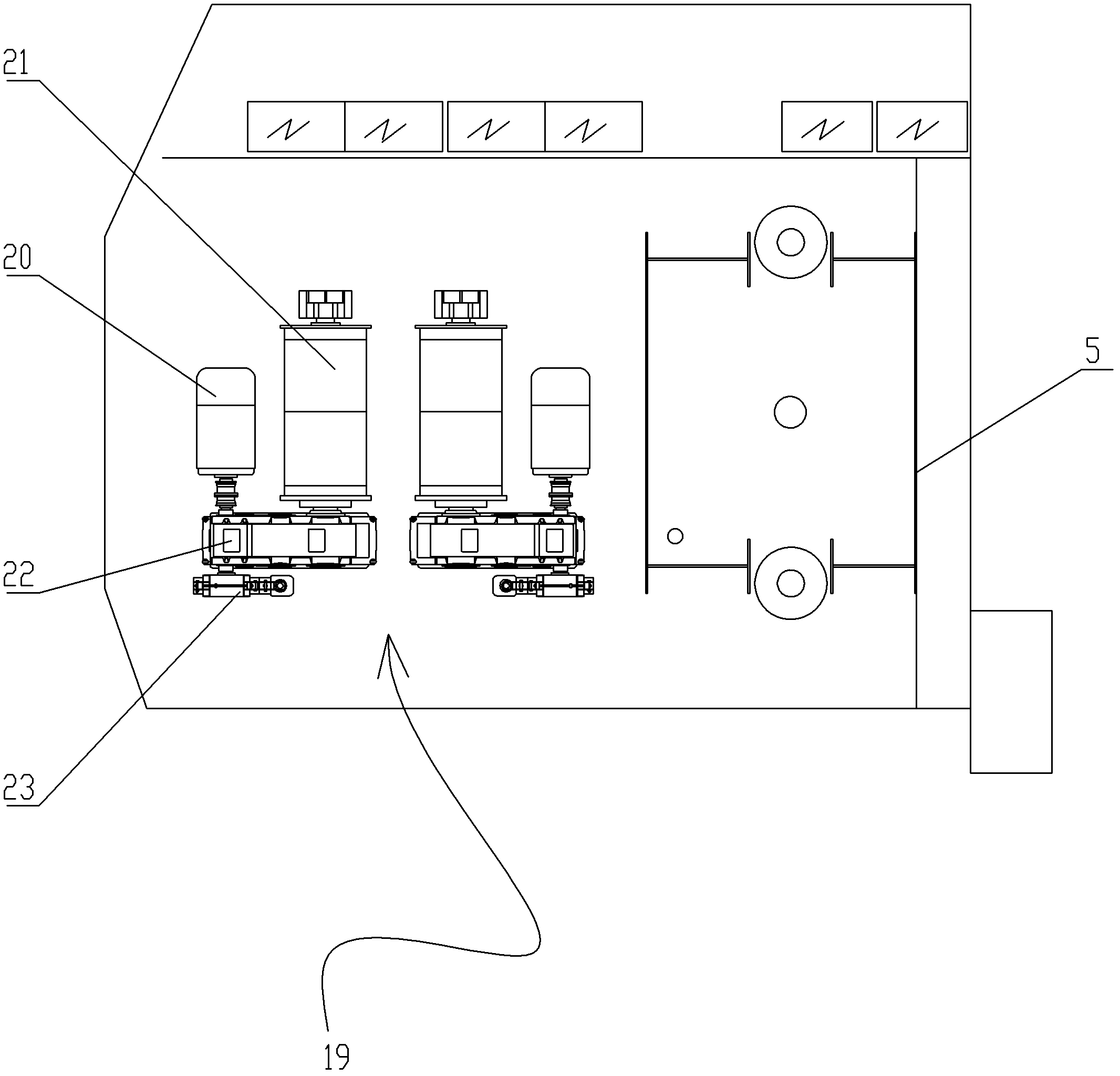

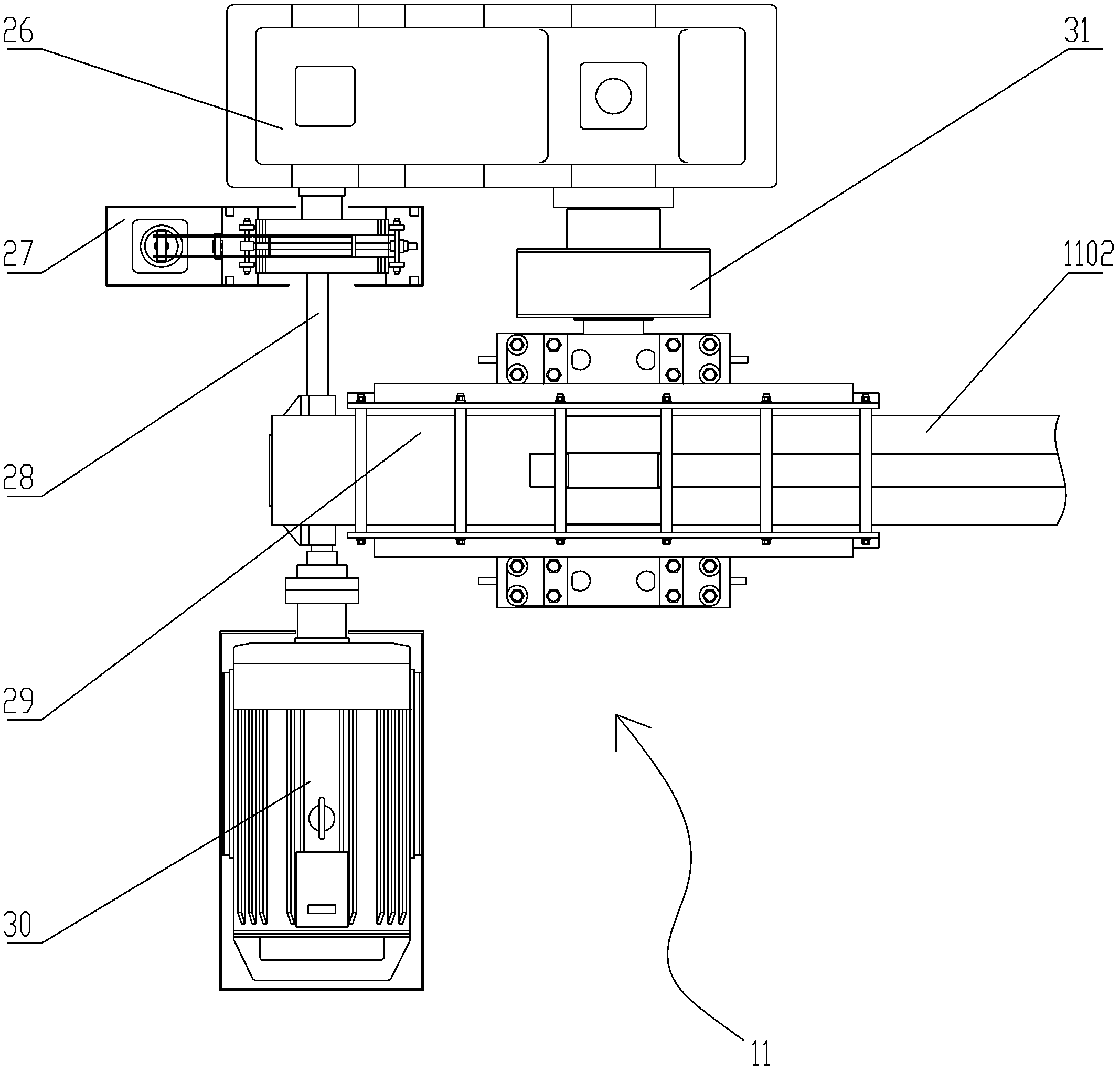

[0021] A multi-purpose single-arm portal crane, comprising a portal frame 1, a running mechanism 2 is provided below the portal frame 1, and a turntable 3 that can rotate relative to the portal frame 1 is provided above the portal frame 1. The rotary table 3. A plate girder column 5 is arranged on the top, and a balance block 20 is provided on the rear side. The lower end of the plate girder column 5 is hinged to the front side with a boom 14, and the front end of the boom 14 is provided with a boom Lifting pulley 16, the upper end of the plate beam type column 5 is provided with a column lifting pulley 7, and a luffing mechanism 11 is provided between the middle part of the plate beam type column 5 and the boom 14. The above-mentioned turntable 3 is provided with a machine room 4, and the above-mentioned lifting driving device 19 is wound with a wire rope 13, and the above-mentioned wire rope 13 goes around the above-mentioned column lifting pulley 7 and the above-mentioned ji...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com