Double-brake loop chain electric hoist

An electric chain hoist and electric hoist technology, applied in the direction of hoisting device, spring mechanism, etc., can solve problems such as safety accidents, inability to provide sufficient safety measures, etc., achieve high safety, small falling stroke, and improve safety performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

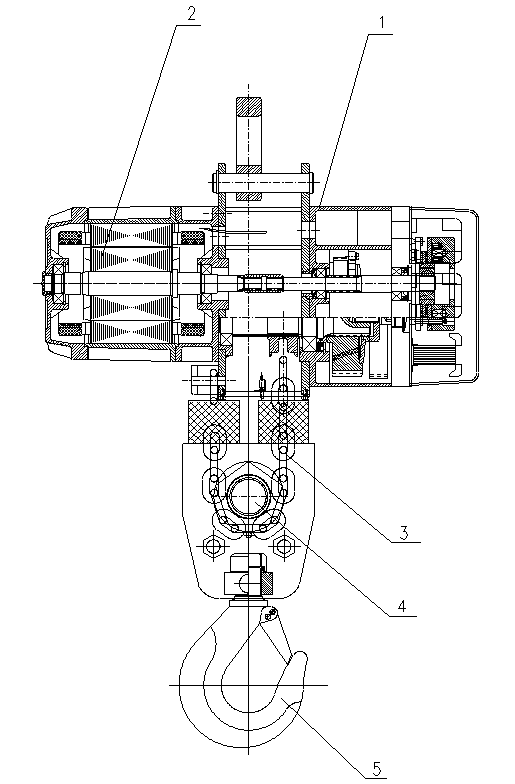

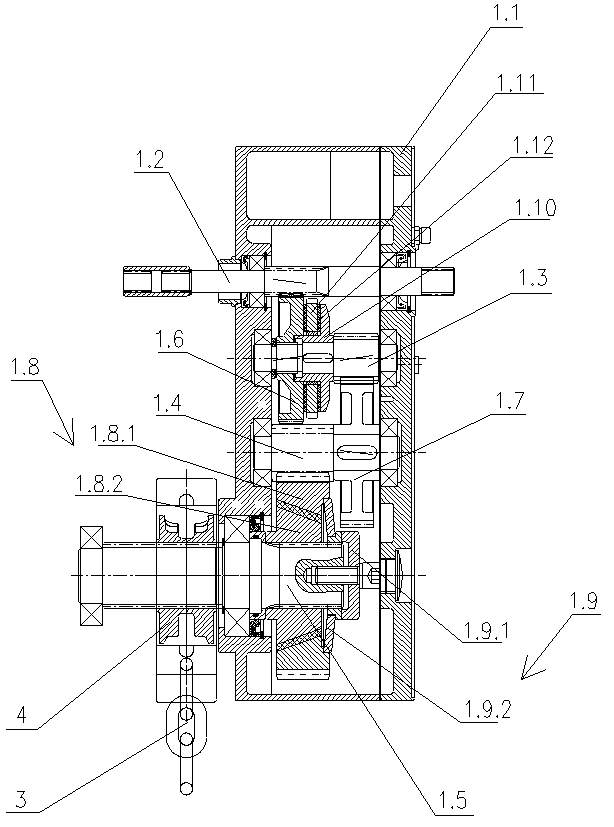

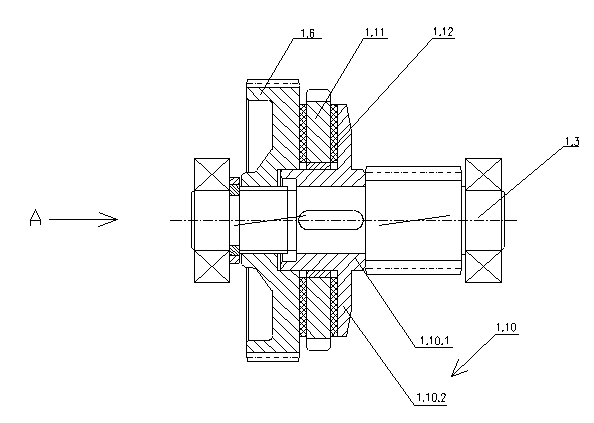

[0020] see Figure 1~3 , the present invention relates to a double-braking electric chain hoist, the electric hoist includes a reduction box 1, a motor 2, a chain 3, a sprocket 4 and a hook 5, the motor 2 is connected to the input shaft of the reduction box 1, The sprocket 4 is set on the output shaft of the reduction box 1, the motor 2 is fixed on the reduction box 1, and the reduction box 1 is a reduction mechanism using a parallel shaft multi-stage transmission wheel, that is, the box of the reduction box 1 The first shaft 1.2, the second shaft 1.3, the third shaft 1.4 and the fourth shaft 1.5 are installed in the body 1.1, and the first transmission wheel 1.6, The secondary transmission wheel 1.7 and the tertiary transmission wheel 1.8, the first shaft 1.2 drives the second shaft 1.3 through engagement with the primary transmission wheel 1.6, and the second shaft 1.3 transmits through the engagement with the secondary transmission wheel 1.7 The third shaft 1.4 is transmit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com