Full-automatic intelligent cut-off water-sealed valve system and method for hot dirty gas

A technology of hot dirty gas and water-sealed valves, which is applied in the sealing of water supply pipeline systems, pipeline systems, engines, etc., can solve the problems of high price, large pipe diameter, tens of thousands or even hundreds of thousands of yuan, and achieve labor saving Cost, the effect of improving reliability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

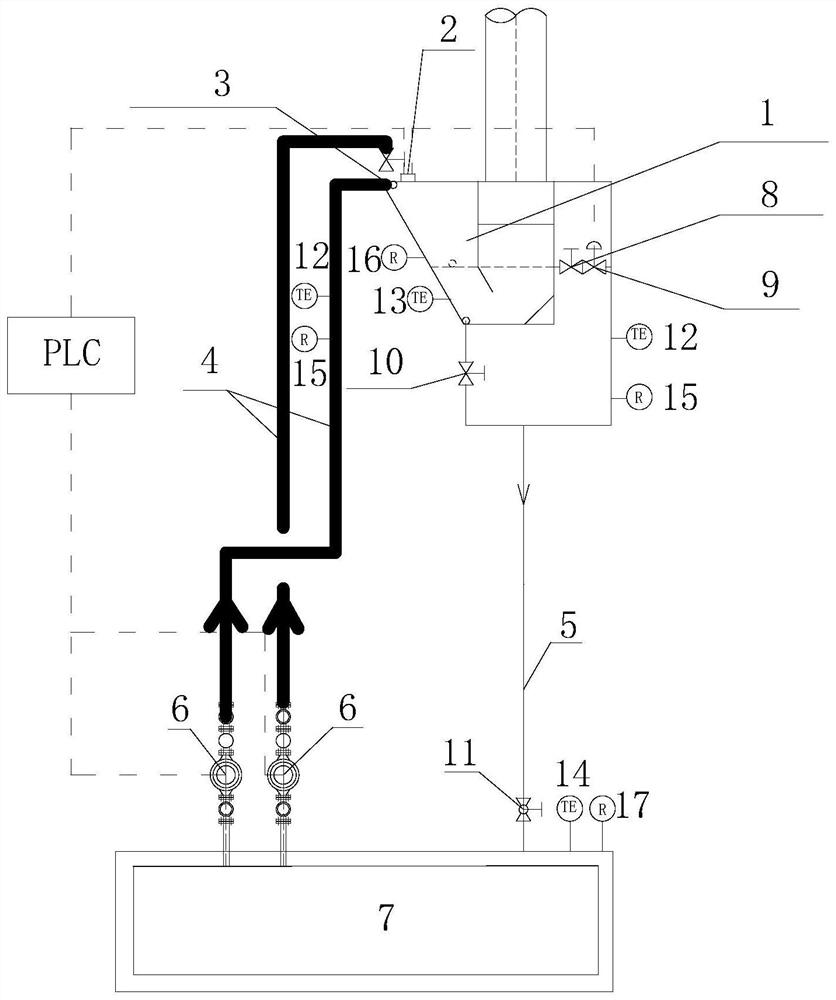

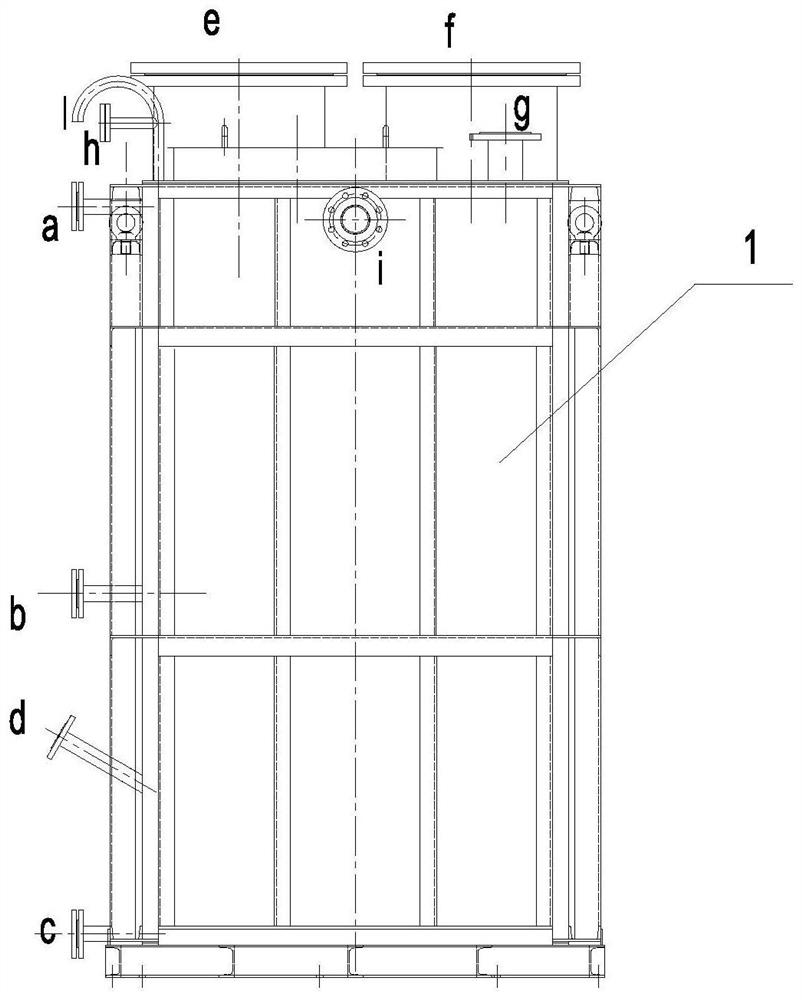

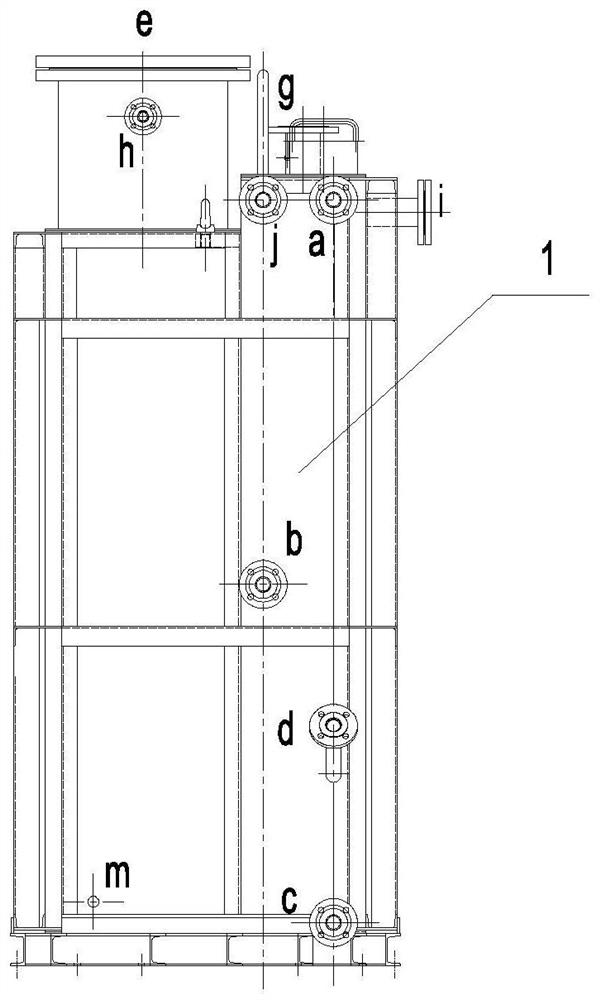

[0030] The specific embodiments provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0031] like Figure 1-3 As shown in the figure, a fully automatic intelligent cut-off water seal valve system for hot dirty gas includes a water seal valve body 1, a radar level gauge 2, a float switch 3, an upper water pipe 4, a return water pipe 5, a water tank 7, Water pump 6 and solenoid valve 9.

[0032] The water seal valve body 1 is a box-type structure, and the top is provided with a gas inlet e, a gas outlet f, and a gas discharge port h; the side wall of the box body is sequentially provided with a high-level water outlet j, a middle-level drain port from top to bottom Water outlet b and low water outlet c; and water inlet a, which is set at the same horizontal position as the high water outlet j, the water inlet a is connected to the outlet of the water pump 6 through the upper water pipe 4, and the inlet of the water pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com